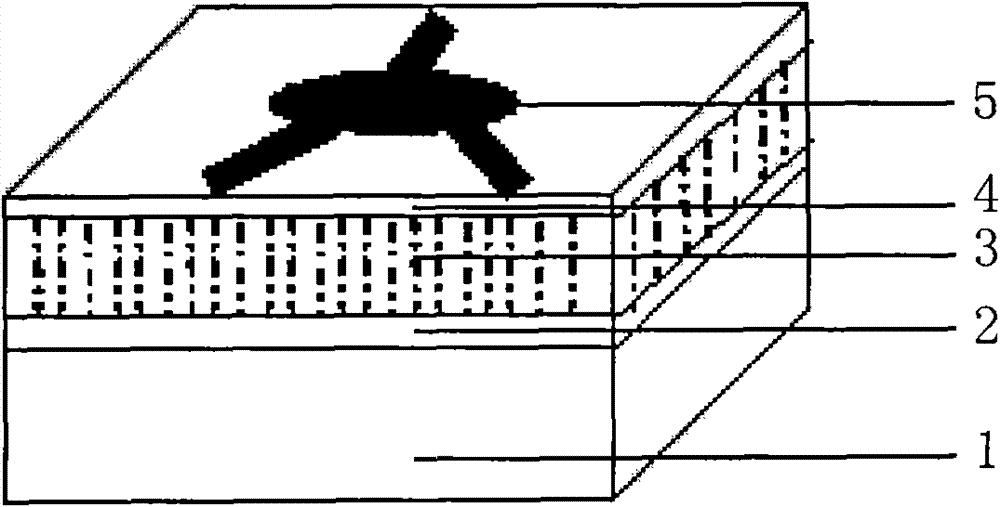

Integrated microstrip circulator and preparation method thereof

A circulator and microstrip technology, applied in the electronic field, can solve problems such as large dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

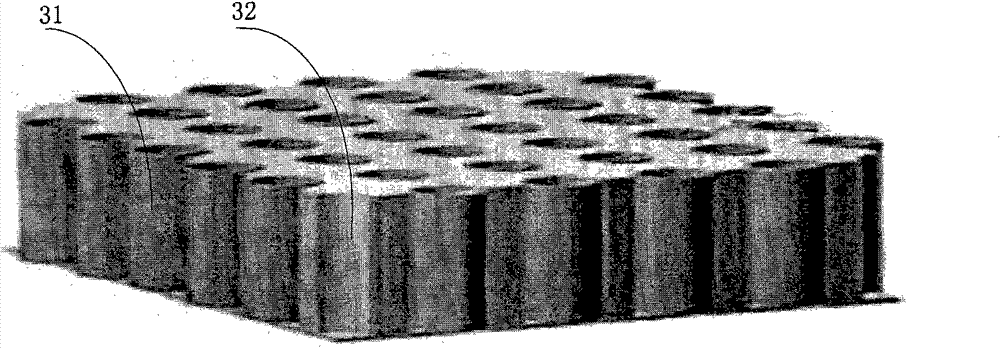

[0028] (1) adopting DC magnetron sputtering method to prepare 2 micron thick gold (Au) film on GaAs substrate;

[0029] (2) Utilize radio frequency magnetron sputtering method to prepare 40 micron thick aluminum film on gold film, the purity of aluminum target is 99.9%;

[0030] (3) the aluminum film that step (2) obtains is put into the H of 70g / L 3 PO 4 In the solution, under the working voltage of 30V and the temperature of 18°C, the first anodic oxidation treatment was performed for 0.5 hours; then the sample after the first oxidation treatment was placed in 70g / L H 3 PO 4 The solution was soaked for 0.5 hours; finally the sample was put into 70g / L H 3 PO 4 In the solution, under the working voltage of 30V and the temperature of 18°C, the first anodic oxidation treatment was performed for 1 hour. Its surface morphology is observed with a scanning electron microscope, and its average pore size is 50nm.

[0031](4) Electroplating elemental magnetic metal cobalt in the ...

Embodiment approach 2

[0038] Except that the secondary anodizing voltage in the step (3) is 45V, other steps are the same as the first embodiment.

Embodiment approach 3

[0040] Except that the secondary anodic oxidation voltage in step (4) is 60V, other steps are the same as that of Embodiment 1.

[0041] Table 1 Implementation Effects

[0042] Example

[0043] In Table 1, the volume reduction ratio and weight reduction ratio of the samples prepared in the three embodiments are compared with the existing separate assembly type circulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com