Light-emitting diode with light filtering film and manufacturing method thereof

A technology of light emitting diodes and filter films, applied in the optical field, can solve the problems of serious light decay, shorten the development time of epitaxy, etc., and achieve the effect of reducing light decay and good production compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

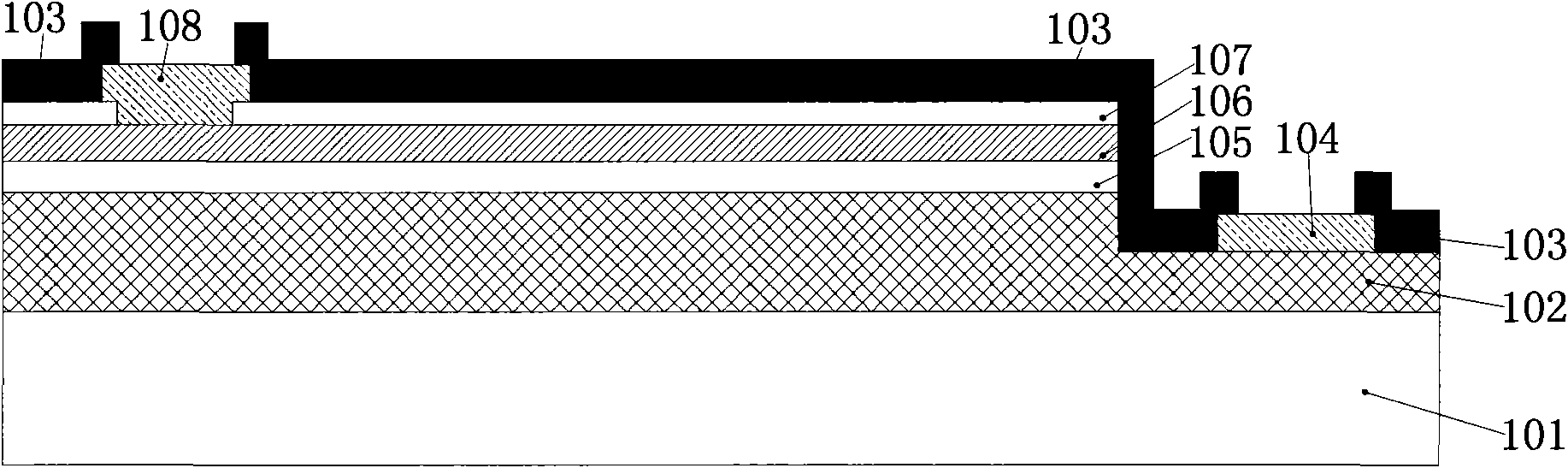

[0015] In the following, the present invention will be described in detail with reference to the accompanying drawings and embodiments.

[0016] Compared with traditional LED chips, the manufacturing process of the LED chip with filter film of the present invention adds processes such as a filter film, and the chip manufacturing process is now described.

[0017] Step 1: Etching part of the epitaxial layer on the GaN epitaxial layer, including the P-type GaN layer 106, the light-emitting layer multi-quantum well structure MQW 105, etch to the N-type GaN layer 102;

[0018] Step 2: depositing a transparent conductive layer 107 on the P-type gallium nitride layer 106 of the light emitting diode;

[0019] Step 3: deposit metals 104 and 108 on the P and N electrodes of the LEDs respectively;

[0020] Step 4: growing the filter film layer 103 in areas other than the P and N electrodes of the light-emitting diodes by electron beam evaporation or ion beam sputtering coating system; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com