Current strengthening and efficient energy saving method of prebaked aluminium electrolysis cell

An aluminum electrolytic cell, high-efficiency and energy-saving technology, applied in the field of aluminum electrolysis, can solve the problems of less than 50% utilization rate of electric energy and high pressure of energy-saving and emission reduction in the aluminum electrolysis industry

- Summary

- Abstract

- Description

- Claims

- Application Information

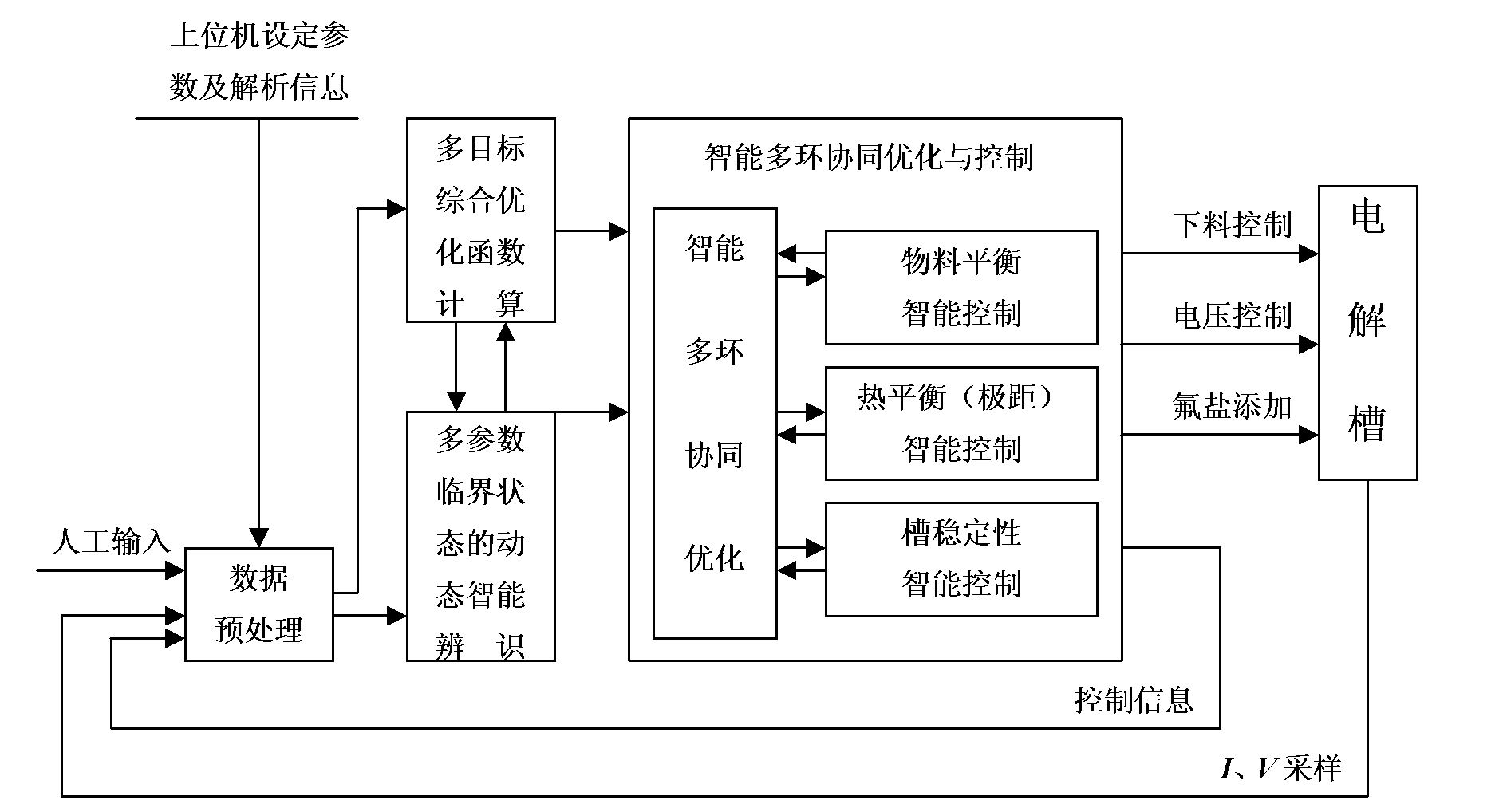

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In the 160kA aluminum electrolysis series and 200kA aluminum electrolysis series of an aluminum plant, through the application of "pre-baked aluminum electrolytic cell current strengthening and high efficiency and energy saving technology", process optimization and control technology transformation and upgrading are carried out online. The main process technical parameters are as follows:

[0062] Anode current density: from 0.72A / cm 2 Increased to 0.83A / cm 2 ;

[0063] Slot working voltage (including the apportioned external busbar voltage drop and other black voltages): reduced from 4.15 to 4.20V to 3.80 to 3.86V (among them, the average working voltage of new slots in the series with a slot age of less than 1 year is 3.66V) ;

[0064] Electrolysis temperature: reduced from 945-955°C to 925-935°C;

[0065] Superheat: 8~12℃;

[0066] Alumina concentration: 1.8-2.5%;

[0067] Anode effect coefficient: ≤0.02 times / tank·day.

[0068] The results of industrial applic...

Embodiment 2

[0070] In the 300kA aluminum electrolysis series and 400kA aluminum electrolysis series of an aluminum plant, through the application of "pre-baked aluminum electrolytic cell current strengthening and high efficiency and energy saving technology", process optimization and control technology transformation and upgrading are carried out online. The main process technical parameters are as follows:

[0071] Anode current density: from 0.72A / cm 2 Increased to 0.81A / cm 2 ;

[0072] Slot working voltage (including black voltage such as apportioned external bus voltage drop): reduced from 4.17 to 4.23V to 3.65 to 3.76V;

[0073] Electrolysis temperature: reduced from 950-965°C to 925-935°C;

[0074] Alumina concentration: 1.8-2.5%;

[0075] Anode effect coefficient: ≤0.018 times / tank·day.

[0076] The results of industrial application and statistical assessment in the past year show that the control accuracy and reliability of process parameters have been significantly improved. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com