Method for preparing carbon nano tube with great inside diameter and controllable length

A carbon nanotube and large inner diameter technology, which is applied in the field of carbon nanotube preparation by catalytic chemical vapor deposition, can solve the problems of uneven tube diameter and uncontrollable length, and achieve the effect of simple equipment, more carbon source and solvent, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

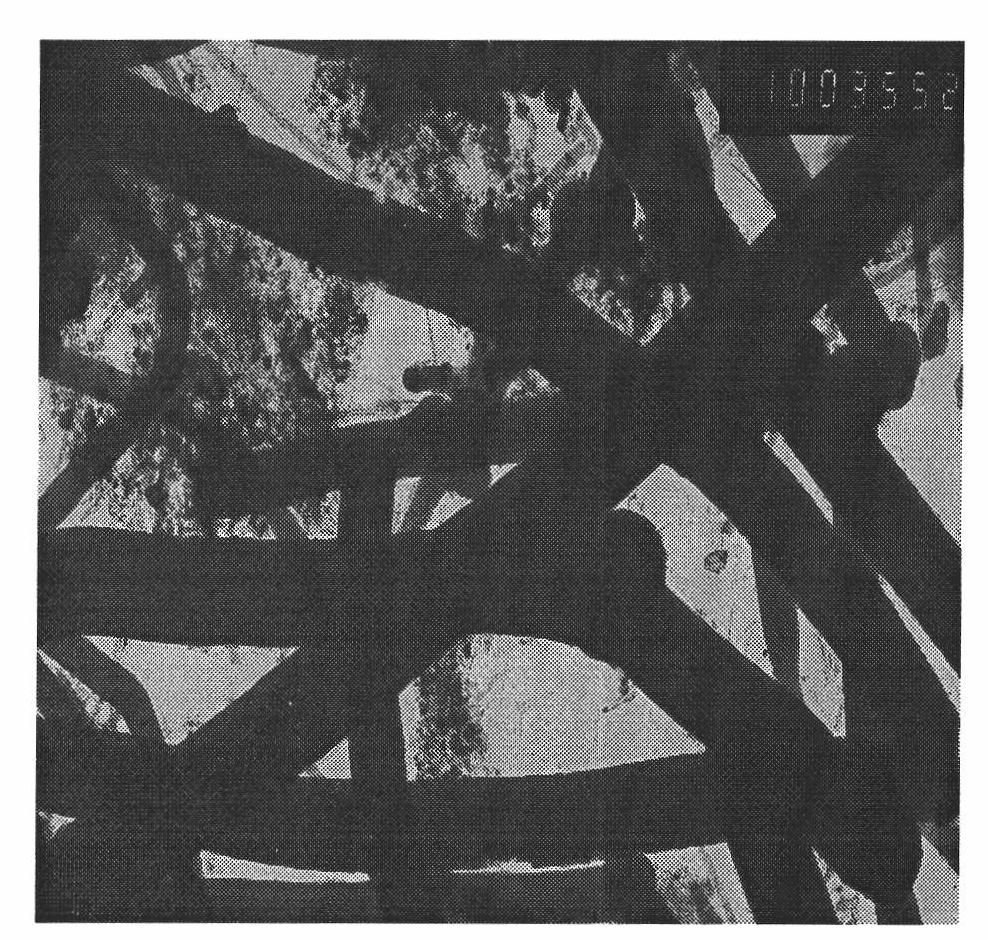

[0022] The synthesis is carried out in a horizontal quartz reactor. Under the condition of nitrogen protection, the temperature is raised to 950 ° C ~ 1100 ° C, the heating rate is 10 ~ 20 ° C / min, and the hydrogen gas is introduced at 10 ~ 100 L / h for about 5 minutes. Finally, the xylene solution in which ferrocene, sulfur, and thiophene are dissolved is input by the advection pump, and the catalyst solution is sprayed into the end of the reactor. The concentration is 50-80mg / ml, the thiophene concentration is 0.2-0.5ml / 100ml, the molar ratio of ferrocene to sulfur is 10:0.5-10:2, the nitrogen flow rate is 50-100L / h, and the reaction time is 60 minutes. The black flocculent product was collected at the end of the quartz tube and the exhaust gas bottle, and was determined to be 100-700nm carbon fibers by scanning electron microscope and transmission electron microscope, and there were amorphous carbon spheres at the same time. The yield was 4-6g, which was 15-20 times that ...

Embodiment 2

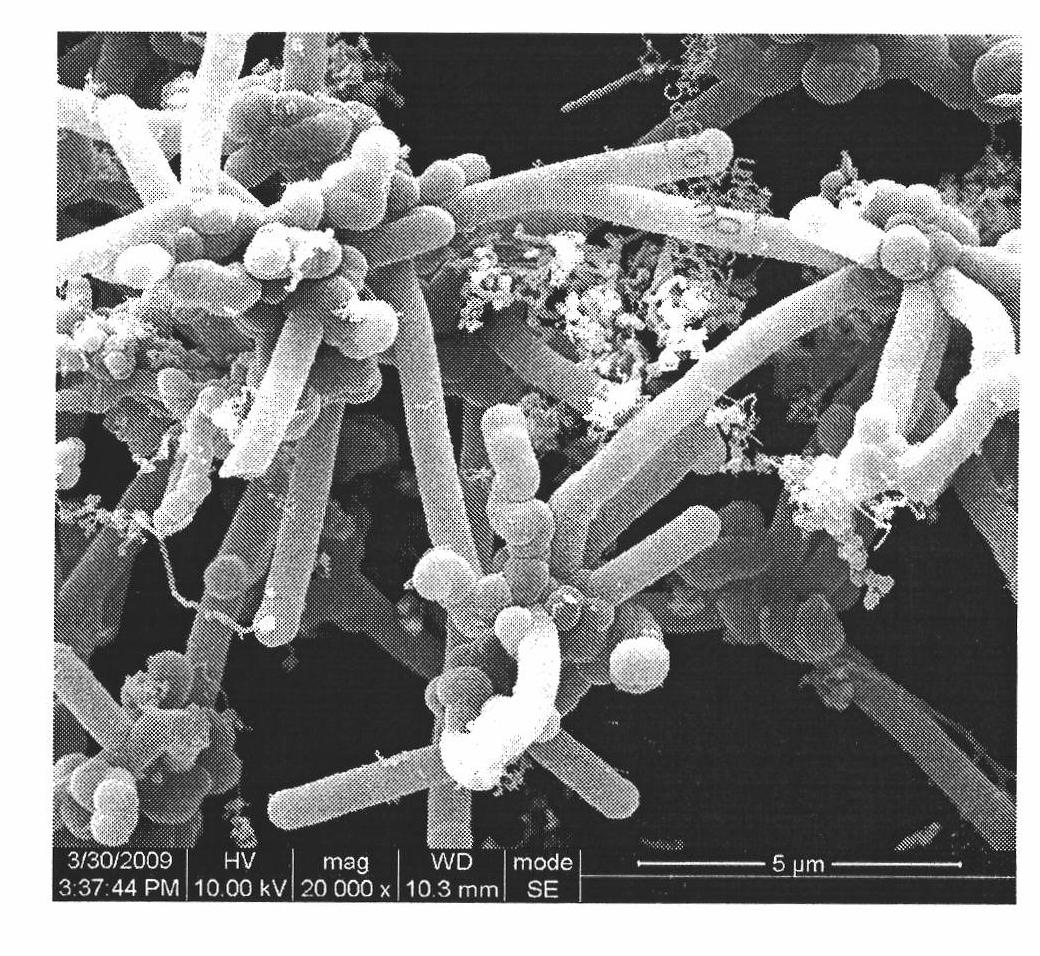

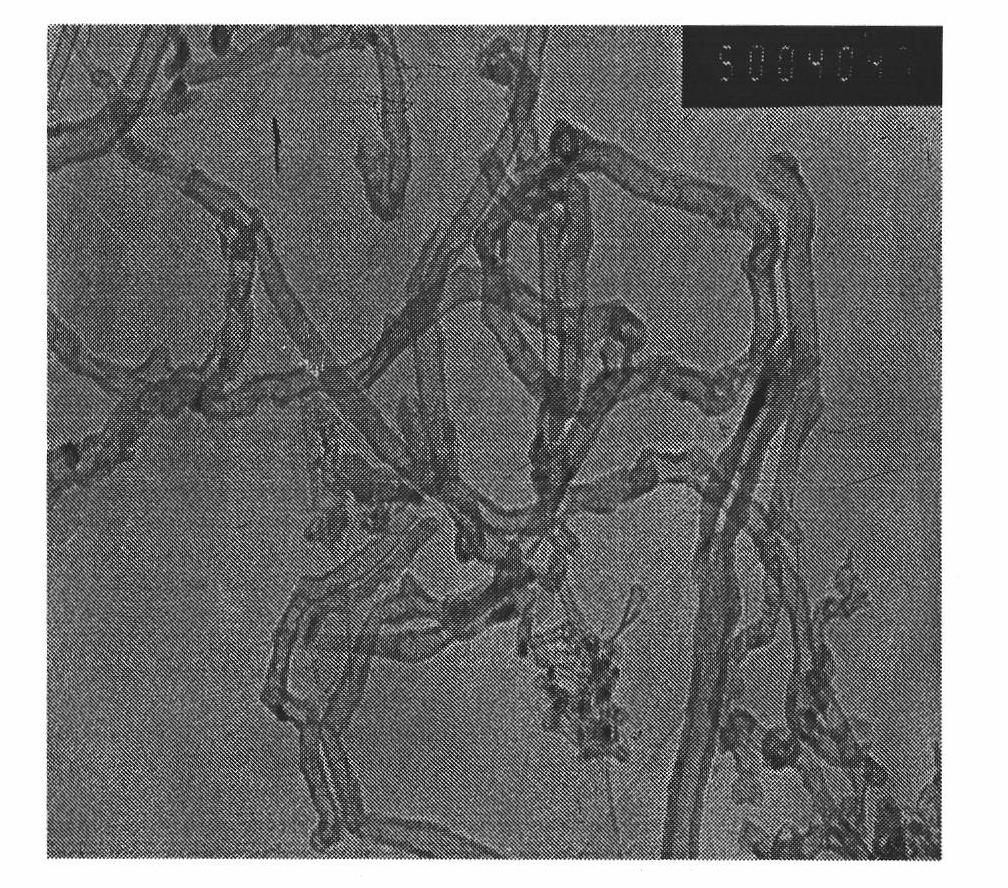

[0024] The synthesis reaction is carried out in a horizontal quartz reactor, and the temperature is raised to 950 ° C ~ 1100 ° C under the protection of nitrogen gas, the heating rate is 10 ~ 20 ° C / min, and hydrogen gas is fed 10 ~ 100 L / h. After about 5 minutes, The xylene ethanol solution dissolved with ferrocene, sulfur, and thiophene is input by a horizontal flow pump, the injection rate is 0.1-0.5ml / min, the volume ratio of ethanol to xylene is 1:1-2:1, and the concentration of ferrocene The concentration of thiophene is 0.2-0.5ml / 100ml, the ratio of ferrocene to sulfur is 10:0.5-10:2, the nitrogen flow rate is 80-100L / h, and the reaction time is 60 minutes. A black flocculent product was collected at the end of the quartz tube and the tail gas bottle, with a yield of 3-5 g, about 15-20 times that of the catalyst. As measured by scanning electron microscope and transmission electron microscope, the tube diameter is 40-70nm multi-walled carbon nanotubes, the inner dia...

Embodiment 3

[0026] The synthesis reaction is carried out in a horizontal quartz reactor, and the temperature is raised to 950 ° C ~ 1100 ° C under the protection of nitrogen gas, the heating rate is 10 ~ 20 ° C / min, and hydrogen gas is fed 10 ~ 100 L / h. After about 5 minutes, The xylene ethanol solution dissolved with ferrocene, nickelocene, sulfur and thiophene is introduced by a convection pump, the injection rate is 0.1-0.5ml / min, the concentration of ferrocene is 30-40mg / ml, ferrocene and The mass ratio of nickelocene is 10:0.02~10:0.05, the concentration of thiophene is 0.2~0.5ml / 100ml, the molar ratio of ferrocene to sulfur is 10:0.5~10:2, and the nitrogen flow rate is 80~100L / h , the reaction time is 60 minutes. A black flocculent product was collected at the end of the quartz tube and the tail gas bottle, with a yield of 3-5 g, about 15-20 times that of the catalyst. As measured by scanning electron microscope and transmission electron microscope, the tube diameter is 40-70nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com