Method for welding circumferential weld between metal thin-wall clad layer and base layer of clad pipe

A welding method and thin metal technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems such as cracks and bad structures, and achieve the effects of ensuring corrosion resistance, increasing effective thickness, and good plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

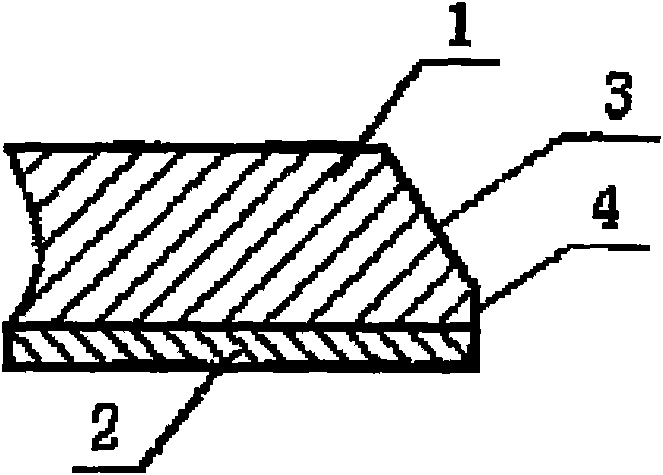

[0024] Embodiment 1: see attached figure 1 . The relative welding of bimetal composite pipes with an outer diameter of 114 mm is taken as an example to illustrate. The thickness of the carbon steel base layer is 12 mm, and the thickness of the stainless steel cladding layer is 1.5 mm.

[0025] (1) Groove processing: use machining method to process a groove with an angle of 30 degrees and a blunt edge of 5 mm at the pipe end. Use a grinding wheel to polish the rust on the carbon steel near the groove, and clean the oil on the groove with acetone.

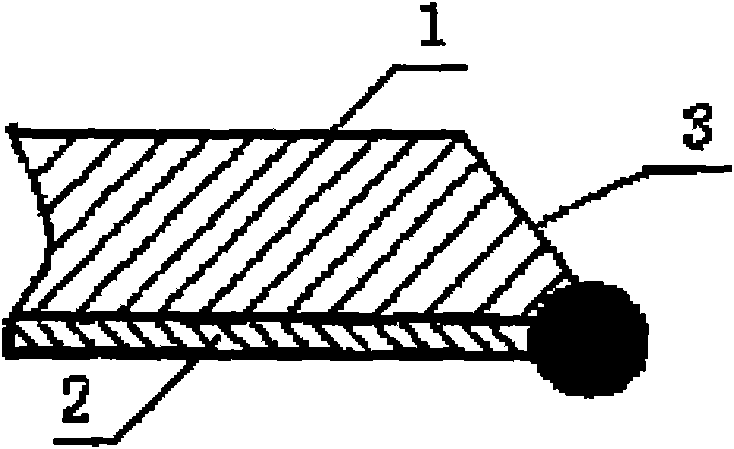

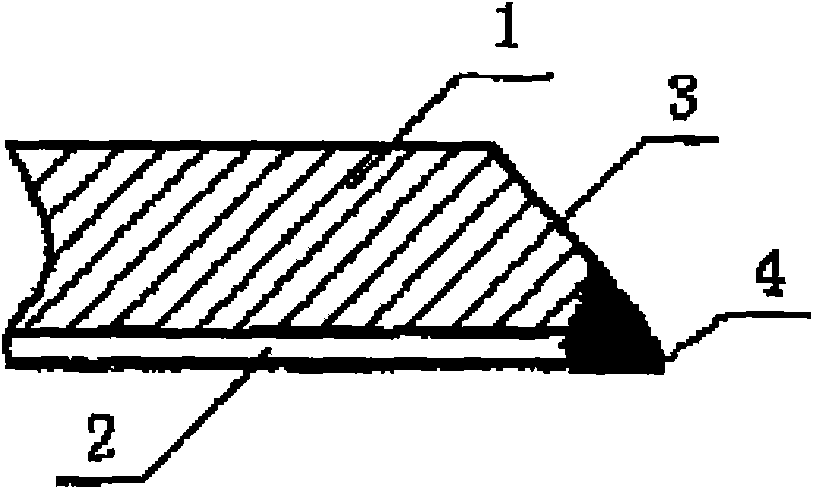

[0026] (2) Sealing welding: Surfacing 2-3 layers of stainless steel on the groove close to the inner surface of the bottom sealing bead. The welding method is argon tungsten arc welding, using 309Mo type austenitic stainless steel wire, the model is ER309MoI. , the grade is HOOCr24Ni13M02, and the diameter is 2 mm. After welding, use a grinding wheel to grind the groove, the angle is 30-35 degrees, and the blunt edge is 0.5 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com