First of all, under the premise of ensuring the setting accuracy of the moisture content of the

discharge material, it is difficult to set and control the temperature of the shredded tobacco after drying within a certain range, and the control accuracy of the shredded tobacco temperature is poor.

Second, the

expansion rate of shredded tobacco cannot be set and controlled during the drying process

The third is that the

drum drying machine has poor moisture control on the head and

tail of the material, that is, the problem that the shredded tobacco of the batch enters the

drum drying machine first and the shredded tobacco that exits the

drum drying machine is too dry

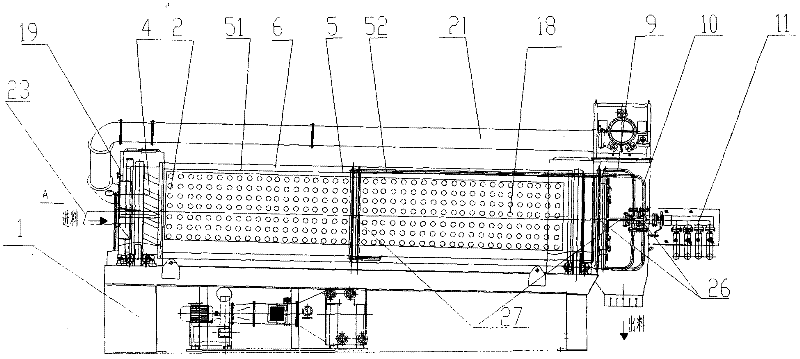

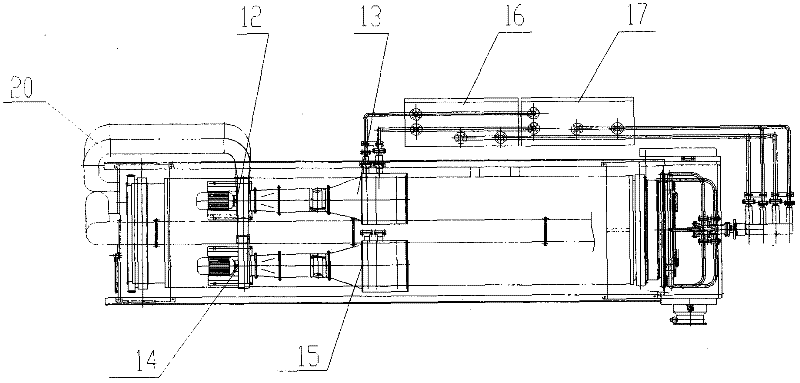

First of all, the drying cylinders of various drum silk drying machines commonly used are one-stage, and the

heat carrier steam used enters the arrangement tubes in the heat exchange plate of the drying cylinder from the rotary joint at the

discharge end, and the steam passes through a round trip and then through the original Rotary joint

discharge, because the length of the drying section is fixed, only by adjusting the amount of steam entering the drying cylinder (that is, adjusting the

steam pressure) can the moisture content of the wet shredded tobacco be reduced to the requirements specified in the process, but the temperature after drying Uncontrollable, because the temperature of the drying cylinder can only be adjusted as a whole, that is to say, in the case of a stable flow of cut tobacco, the higher the moisture content of the cut tobacco, the higher the temperature of the drying cylinder, and the higher the discharge temperature, and vice versa.

In this way, it is difficult to set the temperature of cut tobacco after drying cut tobacco in a certain range.

Second, the drum drying machine is a composite drying technology. The heat exchange plate on the drum wall and the temperature of the hot air are the most important

key factors to control the

expansion rate of the cut tobacco. Since there is almost no

temperature gradient in the length of the one-stage

drying drum, it cannot be based on The expansion process of shredded tobacco needs to select the expansion temperature of the drying cylinder in a targeted manner, and the hot air must pass through the entire inner cavity of the drum no matter whether it is forward or countercurrent. Decreasing,

humidity is also increasing, drying efficiency is constantly decreasing

The downstream hot air that just entered the drum dryer will play a certain role in the expansion of the cut tobacco, but it still cannot control the

expansion rate of the cut tobacco

Third, there are currently many measures to control the moisture of the head and

tail of the drum drying machine, such as increasing the feed amount of shredded tobacco, increasing the rotation speed of the drum, increasing the

wind speed of the hot air, and reducing the pressure of the steam, etc. , but still passively solve

At present, domestic tobacco

processing enterprises are also paying more and more attention to the work of energy saving and consumption reduction. At present, steam is generally used as the heat exchange carrier in drum drying machines, and the

utilization rate of steam

heat energy is low. A large amount of steam used by the

heat exchanger of the

neutralization hot air

system is discharged into the environment,

wasting heat and affecting the environment

The temperature of the drying cylinder is controlled by adjusting the amount of steam entering the drying cylinder (that is, adjusting the

steam pressure). The pipes in the heat exchange plate cannot be filled with steam, and the

temperature difference on the surface of the drying cylinder is large, which is not conducive to the effective use of heat by the shredded tobacco. Absorption, which affects the uniformity of tobacco drying

In addition, unstable factors such as steam quality,

steam pressure regulation, and hydrophobic system will also seriously affect the quality of silk drying

At the same time, the supporting pipeline of the steam heat exchange system needs to be equipped with a large number of high-quality imported valves, which increases the configuration cost of the equipment

Login to View More

Login to View More  Login to View More

Login to View More