Crude rubber production system

A production system and raw rubber technology, applied in the field of raw rubber production system, can solve the problems of polluted materials, glue filaments easy to adhere to the kettle wall, troublesome mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0076] See figure 1 As shown in Figure 14, the raw rubber production system of this embodiment includes a raw rubber dehydration device 1, a raw rubber polymerization reaction device 2, a raw rubber removal low molecular device 3, a raw rubber receiver and a rubber output device 4, and a hot oil circulation heating device 6. Vacuumizing device 7, nitrogen supply device 8 and cooling water circulation cooling device 9.

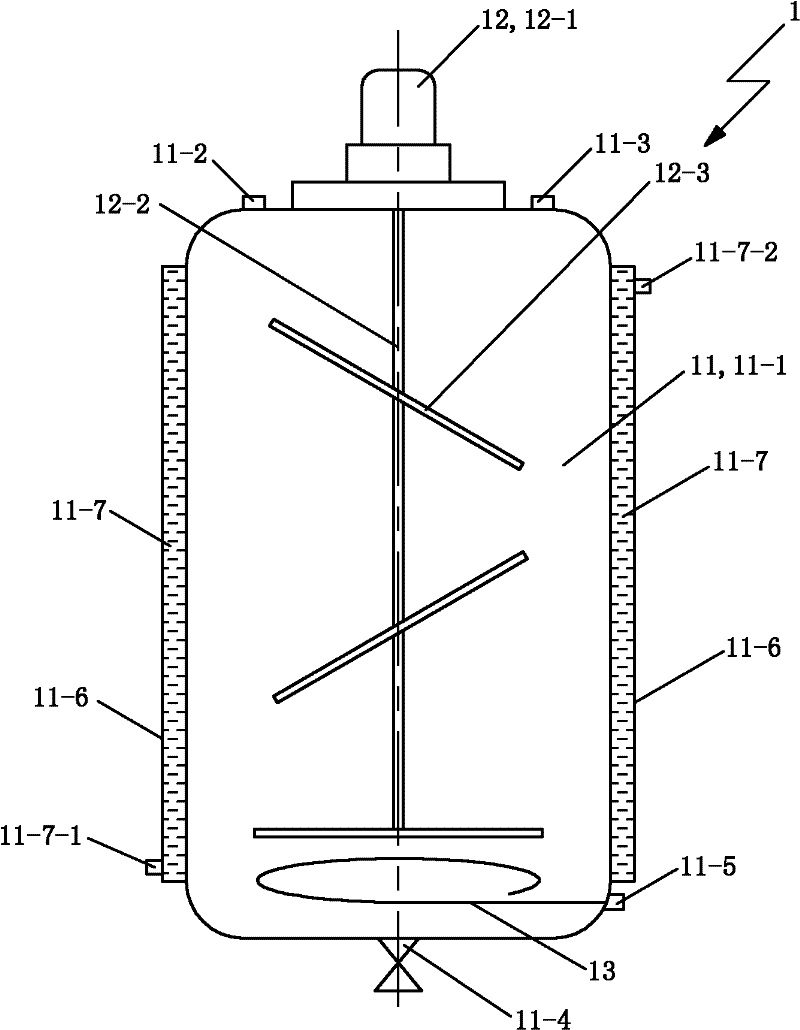

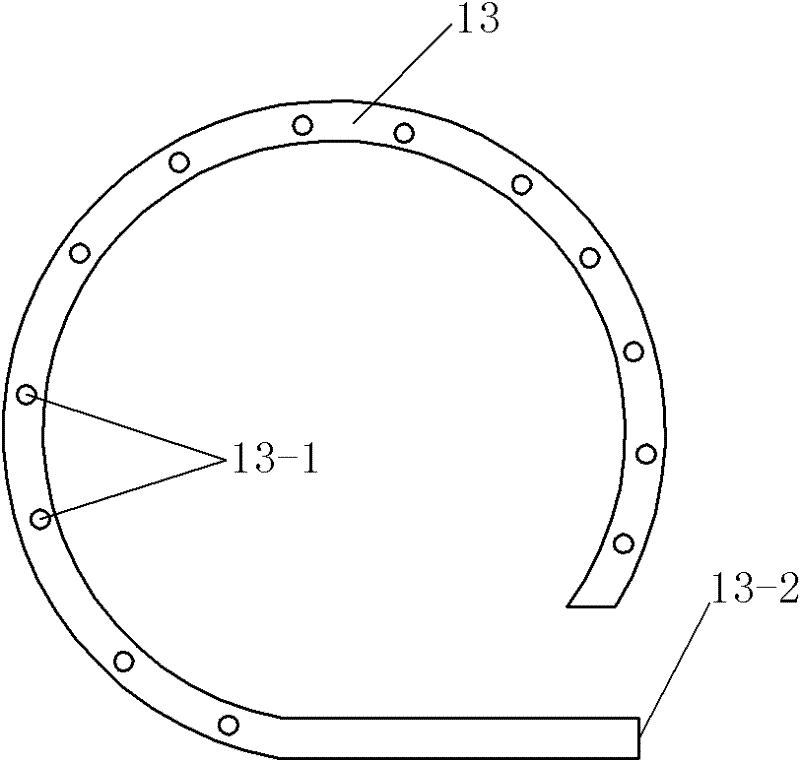

[0077] See figure 2 , The raw rubber dehydration device 1 includes a dehydration kettle 11 , a dehydration kettle stirring mechanism 12 and a nitrogen coil 13 .

[0078] The dehydration kettle 11 includes a dehydration kettle body 11-1, a dehydration kettle vacuum interface 11-2, a dehydration kettle feeding interface 11-3, a first discharge valve 11-4, a nitrogen delivery interface 11-5 and a dehydration kettle. Kettle jacket plate 11-6. The dehydration kettle jacket plate 11-6 and the dehydration kettle body 11-1 together constitute the dehydration kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com