Modified tempering furnace and tempering method

A tempering furnace, inert gas technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of uneven tempering, mold oxidation, high price, and achieve good tempering effect, uniform hardness and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

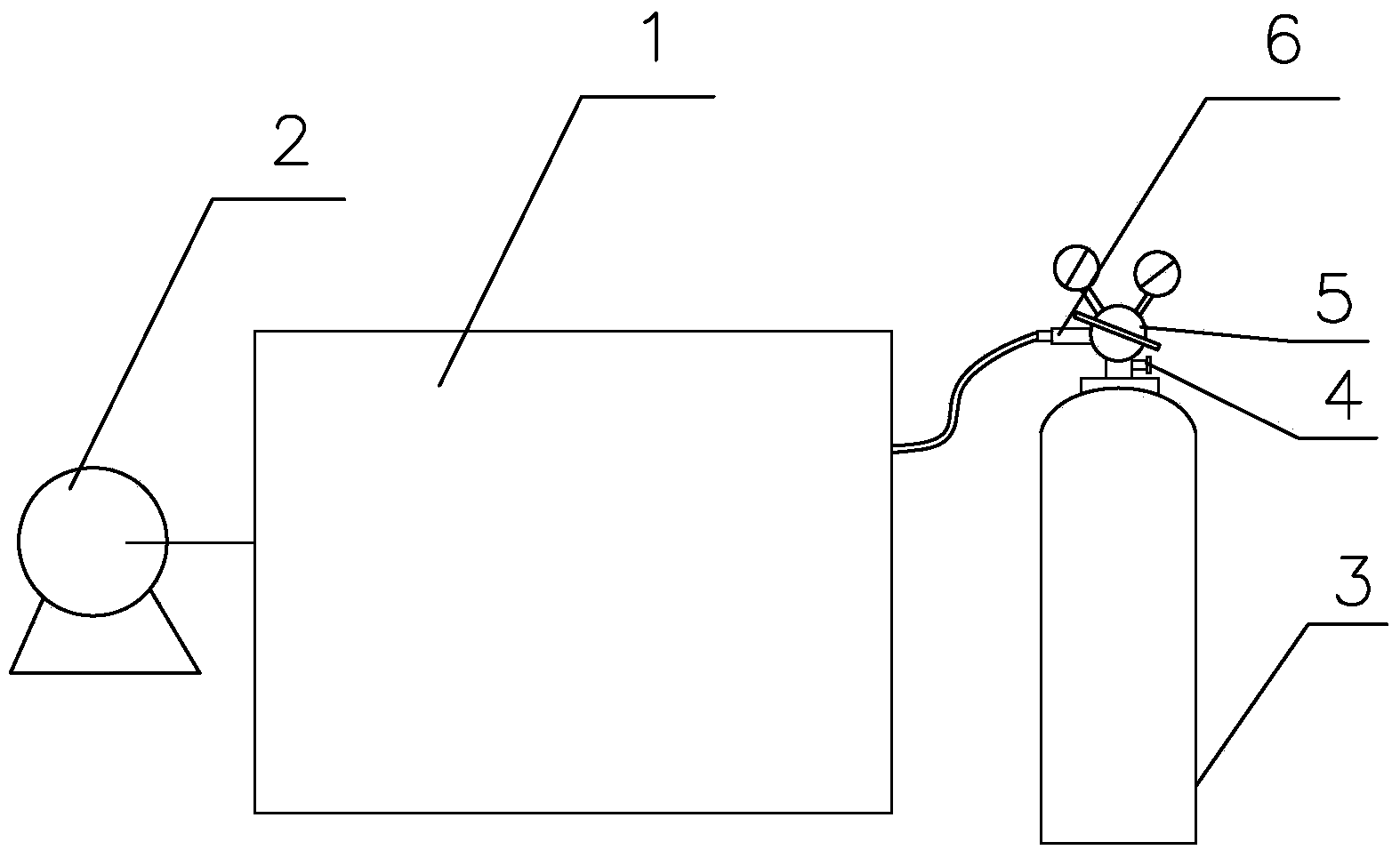

[0038] Such as figure 1 , an improved tempering furnace, comprising a common tempering furnace 1 (the inside is air during tempering), and a set of vacuum pumping equipment (vacuum pump) 2 and a set of inert gas charging equipment are installed on the furnace body of the tempering furnace 1.

[0039] The inert gas inflation equipment includes an inert gas compression bottle 3, and a safety valve 4, a decompression valve 5 and an inflation valve 6 sequentially arranged on its gas outlet pipeline.

[0040] The gas in the inert gas compression bottle is one of nitrogen, helium and argon.

[0041] In this example, cheap high-purity nitrogen is selected.

[0042] Use the improved tempering equipment to work, the tempering method is as follows:

[0043] First, the temperature of the tempering furnace rises from room temperature to 200°C within 30 minutes. During this process, start the vacuum equipment (vacuum pump) to evacuate the tempering furnace to remove air, and the vacuum d...

Embodiment 2

[0052] Utilize the improved tempering equipment in embodiment 1 to work, the tempering method is as follows:

[0053] First, the temperature of the tempering furnace rises from room temperature to 200°C within 30 minutes. During this process, start the vacuum equipment (vacuum pump) to evacuate the tempering furnace to remove air, and the vacuum degree is evacuated to 600pa.

[0054]Secondly, when the furnace temperature rises to 200°C, fill high-purity nitrogen into the furnace, and then start the circulating fan to heat up and temper. Add a trachea to the outlet of the nitrogen gas, and the trachea extends below the water surface, and judge by observing the speed at which the bubbles emerge. As long as the bubbles come out at a constant speed, it means that the inside is under positive pressure. Continue to heat up to 650°C and keep the temperature constant for 8 hours.

[0055] Finally, after tempering, the hot nitrogen gas is released, and when the nitrogen gas is refill...

Embodiment 3

[0057] Utilize the improved tempering equipment in embodiment 1 to work, the tempering method is as follows:

[0058] First, the temperature of the tempering furnace rises from room temperature to 200°C within 30 minutes. During this process, start the vacuuming equipment (vacuum pump) to evacuate the tempering furnace to remove air, and the vacuum degree reaches 800pa.

[0059] Secondly, when the furnace temperature rises to 200°C, fill high-purity nitrogen into the furnace, and then start the circulating fan to heat up and temper. Add a trachea to the outlet of the nitrogen gas, and the trachea extends below the water surface, and judge by observing the speed at which the bubbles emerge. As long as the bubbles come out at a constant speed, it means that the inside is under positive pressure. Continue to heat up to 620°C and keep the temperature constant for 7 hours.

[0060] Finally, release the hot nitrogen after tempering, and then fill it with nitrogen to cool to 200°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com