Medicinal oxygen-containing beta titanium alloy for orthopedic implantation and preparation method thereof

A beta titanium alloy and titanium alloy technology, applied in the field of oxygen-containing medical beta titanium alloy and its preparation, can solve the problems of low elastic modulus, low alloy strength, and alloy strength less than 600MPa, and achieve low elastic modulus and comprehensive performance. Improved, strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

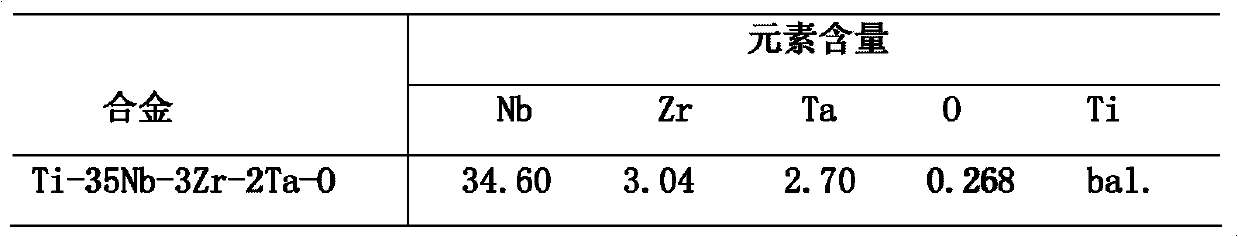

[0021] Ti-Nb-Zr-Ta-O alloy was prepared by vacuum non-consumable melting method. The Ti-Nb-Zr-Ta alloy melted by vacuum autogenous melting was cut into bulk samples. Cut 80g alloy block, add TiO 2 Powder 0.27g. The weight percent of the button ingot is: Ti: 60%, Nb: 35%, Zr: 3%, Ta: 2%, O: 0.13wt%. The raw materials are smelted in a magnetron tungsten button electric arc furnace. The vacuum degree of the melting furnace is 6.6×10 -3 Pa, the lifting of the tungsten electrode is driven by a micro-motor; the arc ignition method is high-frequency spark ignition, and the high-frequency safety device is automatically cut off after the arc is ignited. The general working current is 700-800A, and the maximum melting current is 1250A. Electromagnetic stirring device is used in the melting process to ensure that each component fully reacts and melts evenly. In order to ensure the uniformity of the ingredients, after each sample was smelted, it was turned over and remelted, and the ...

Embodiment 2

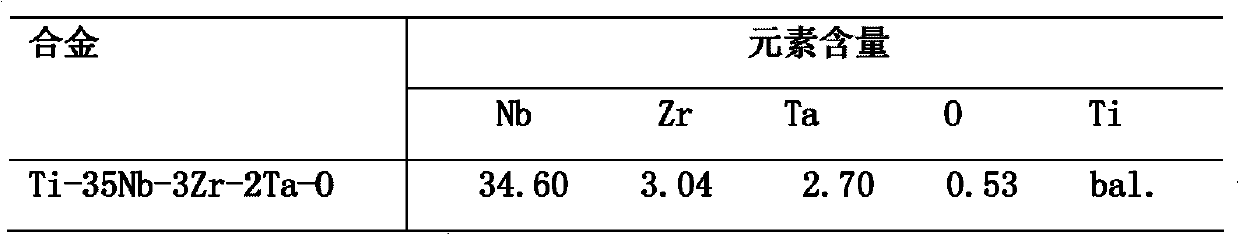

[0026] Other conditions are with embodiment 1, add TiO 2 The powder is 0.53g, and the weight percent of the button ingot is: Ti: 65%, Nb: 35%, Zr: 3%, Ta: 2%, O: 0.26wt%. The chemical composition of the sample is shown in Table 3. The measured room temperature tensile performance data is:

[0027] Tensile strength: 756.86MPa, yield strength: 558.33MPa, modulus of elasticity: 65.00GPa, elongation: 17.80%.

[0028] Table 3Ti-35Nb-3Zr-2Ta-O (wt%) chemical composition

[0029]

Embodiment 3

[0031] Other conditions are with embodiment 1, add TiO 2 The powder is 0.80g, and the weight percent of the button ingot is: Ti: 65%, Nb: 35%, Zr: 3%, Ta: 2%, O: 0.40wt%. The chemical composition of the sample is shown in Table 4. The measured room temperature tensile performance data is:

[0032] Table 4Ti-35Nb-3Zr-2Ta-O (wt%) chemical composition

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com