Method for treating arsenic-containing material by using electric arc furnace

An electric arc furnace and electric arc furnace smelting technology, which is applied in the field of comprehensive recovery of arsenic and valuable metals, can solve the problems of high environmental protection treatment costs, poor working environment, and high labor intensity, and achieve strong equipment adaptability, low noise pollution, and occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

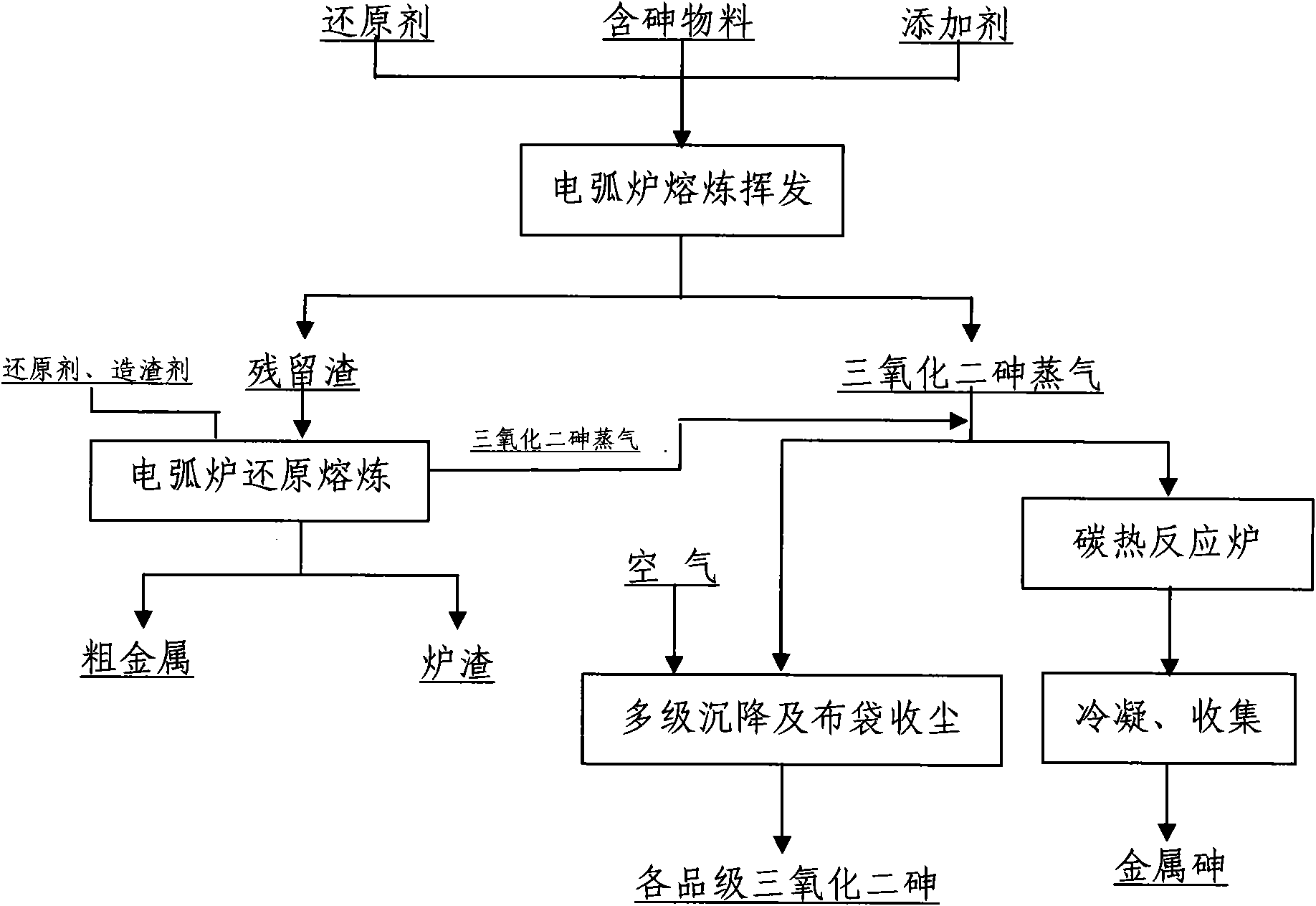

Image

Examples

Embodiment 1

[0016] Mix 1000Kg of tin-arsenic ash (composition as shown in Table 1) with 1% coke powder with a particle size of 0.1-5.0mm, and 3% quartz sand and calcium oxide with a particle size of 1.0-40mm, and use a screw feeder to pass the material through the electrode The hollow hole is added to a 1250KVA DC electric arc furnace with a negative pressure of -20±5Pa, the temperature of the furnace top is controlled at 800±50°C, and the temperature of the molten pool is kept at 1100±50°C to volatilize the arsenic trioxide. 3 / h flow rate of air, cooling and multi-stage sedimentation, the sedimentation temperature is 500 ~ 80 ℃, and 710Kg of the product is collected. Wherein, the purity in No. 2, No. 3, and No. 4 settling chambers reaches more than 99%, and the productive rate is 85% (the settling chambers are No. 1, No. 2, No. 3, and No. 4 from the furnace to the bag dust collector), and No. 1 settling chambers The purity of arsenic trioxide in the chamber is over 95%, and the purity o...

Embodiment 2

[0020] A 600KVA AC electric arc furnace is used to treat arsenic-containing materials produced by bag dust collection in copper smelting furnaces. The main components are: As57.98%, Cu0.20%, Pb4.47%.

[0021] Mix 500Kg of the above-mentioned arsenic-containing material into 2% coke with a particle size of 0.1-5.0mm, 3% quartz sand with a particle size of 1.0-40mm and calcium oxide, and then use a screw feeder to feed the material into the negative pressure from the furnace side feed port. In the electric arc furnace at -30±5Pa, the furnace top temperature is controlled at 800±50°C, the temperature of the molten pool is kept at 1000±50°C, and the arsenic trioxide obtained by volatilization directly enters the carbon thermal reduction furnace for reduction, and the reduction temperature is 800±20 °C, the reduced metal arsenic vapor is condensed at 350 °C to room temperature, and 99% of the metal arsenic is collected, and the total yield of arsenic is >98%. The residue is added w...

Embodiment 3

[0023] Secondary zinc oxide fumes (smoke produced by fuming furnaces to process lead-zinc closed blast furnace slag) mainly consist of Zn50%, Pb4%, As25%.

[0024] Add 1000kg of the above-mentioned ingredients to the coke with a particle size of 0.1-5.0mm and 5% quartz sand with a particle size of 1.0-40mm, calcium oxide and other additives, and then add the materials to the furnace top. In the 1250KVA DC electric arc furnace, the furnace top temperature is controlled at 600±50°C, the melting temperature is 900±50°C for volatilization of arsenic trioxide, and the volatilized arsenic trioxide vapor is injected into 10Nm 3 / h flow rate of air, cooling and multi-stage sedimentation, the sedimentation temperature is 500 ~ 80 ℃, 291 kg of diarsenic trioxide products of different qualities are collected, and the yield of arsenic trioxide with quality > 96% is > 92%. The primary volatilization rate of arsenic is more than 95%, and the arsenic content in the residue is less than 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com