Optical film, preparation method of the same, and liquid crystal display comprising the same

A technology of optical film and liquid crystal alignment layer, applied in the field of optical film, can solve the problems of liquid crystal film peeling, low polymer mobility, electrostatic discharge, etc., and achieve the effect of improving durability and excellent adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] In addition, the present invention also provides a preparation method of the above-mentioned optical film, the method comprising the following steps: 1) coating the composition for the liquid crystal alignment layer on the substrate based on the acetyl cellulose film, and drying to form a coating , and then irradiating ultraviolet rays to form a liquid crystal alignment layer, the composition comprising: a) a photoreactive polymer selected from a norbornene-based photoreactive polymer containing a cinnamate group, a photoreactive polymer containing a unit represented by Chemical Formula 1 One or more photoreactive polymers in the photoreactive polymer containing the unit represented by Chemical Formula 2, b) a multifunctional monomer crosslinkable with the photoreactive polymer, c) a photosensitive trigger and d) an organic solvent; and 2) coating a liquid crystal compound solution on the liquid crystal alignment layer, drying it, and then irradiating ultraviolet rays th...

Embodiment 1

[0105] As shown in Table 1 below, 5-norbornene-2-methyl-(4-methoxycinnamate) as a photoreactive polymer, dipentaerythritol hexaacrylate as a polyfunctional monomer, and Irgacure 907 (Swiss, Ciba-Geigy) as a photoinitiator was dissolved in toluene at concentrations of 2 wt%, 2 wt% and 0.5 wt%, respectively. The composition solution for the liquid crystal alignment layer prepared according to the above composition is coated on an acetylcellulose substrate with a thickness of 80 microns to a dry thickness of and dried with hot air in an oven at 70° C. for 2 minutes to form a liquid crystal alignment layer.

[0106] The liquid crystal alignment layer was cured once at a rate of 3 m / min by using a wire grid polarizing plate (Moxtek) and a high pressure mercury lamp of 80 w / cm in polarized UV perpendicular to the direction of the substrate to provide alignment.

[0107] Based on 100 parts by weight of the total solution, a mixed solid of 95 wt % of a polymeric liquid crystal compo...

Embodiment 2

[0113] In the same manner as in Example 1, except that tris[2-(acryloyloxy)ethyl]isocyanurate was used instead of dipentaerythritol hexaacrylate as the polyfunctional monomer (as shown in Table 2 below). Preparation of liquid crystal film.

[0114] Table 2

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

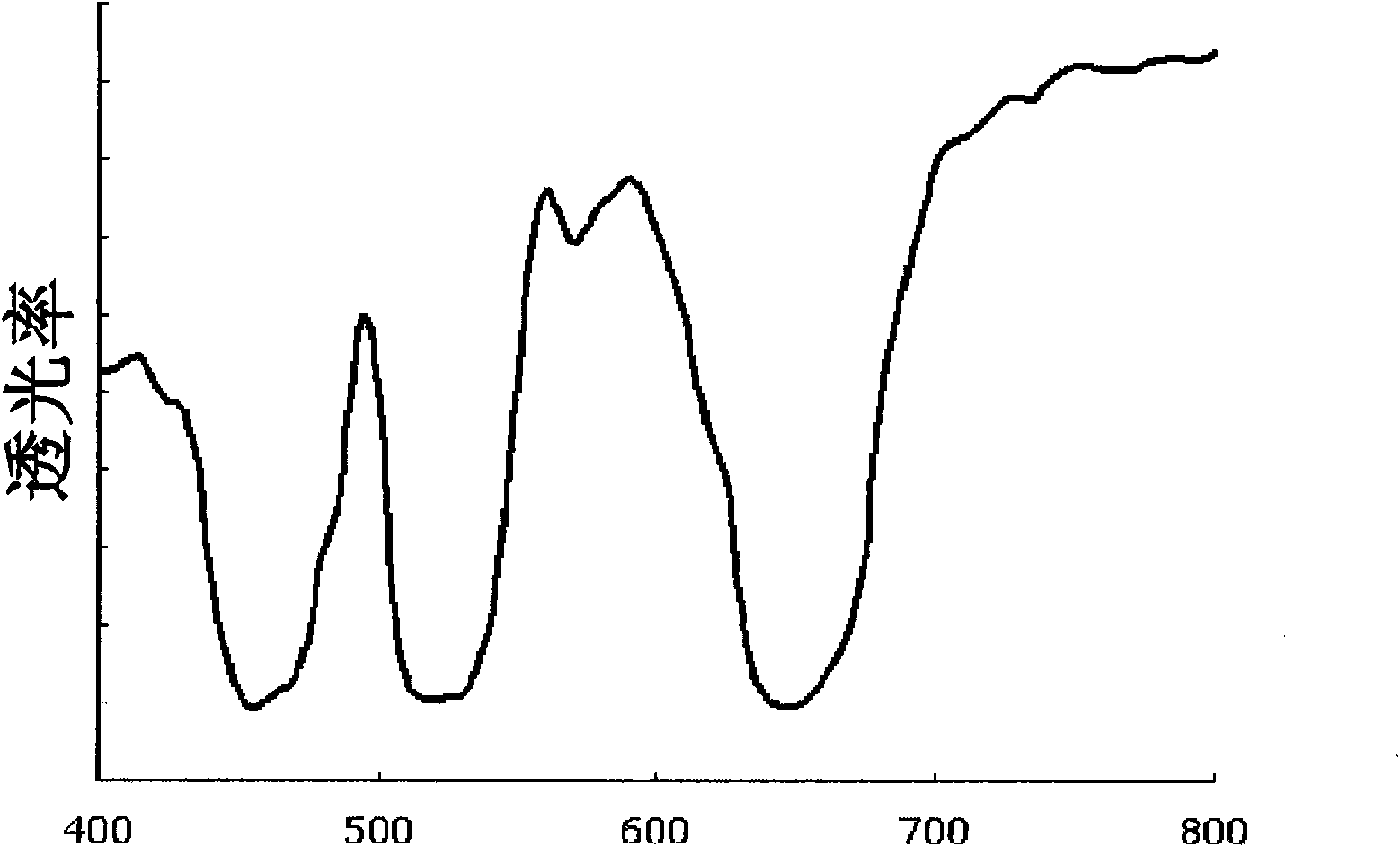

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com