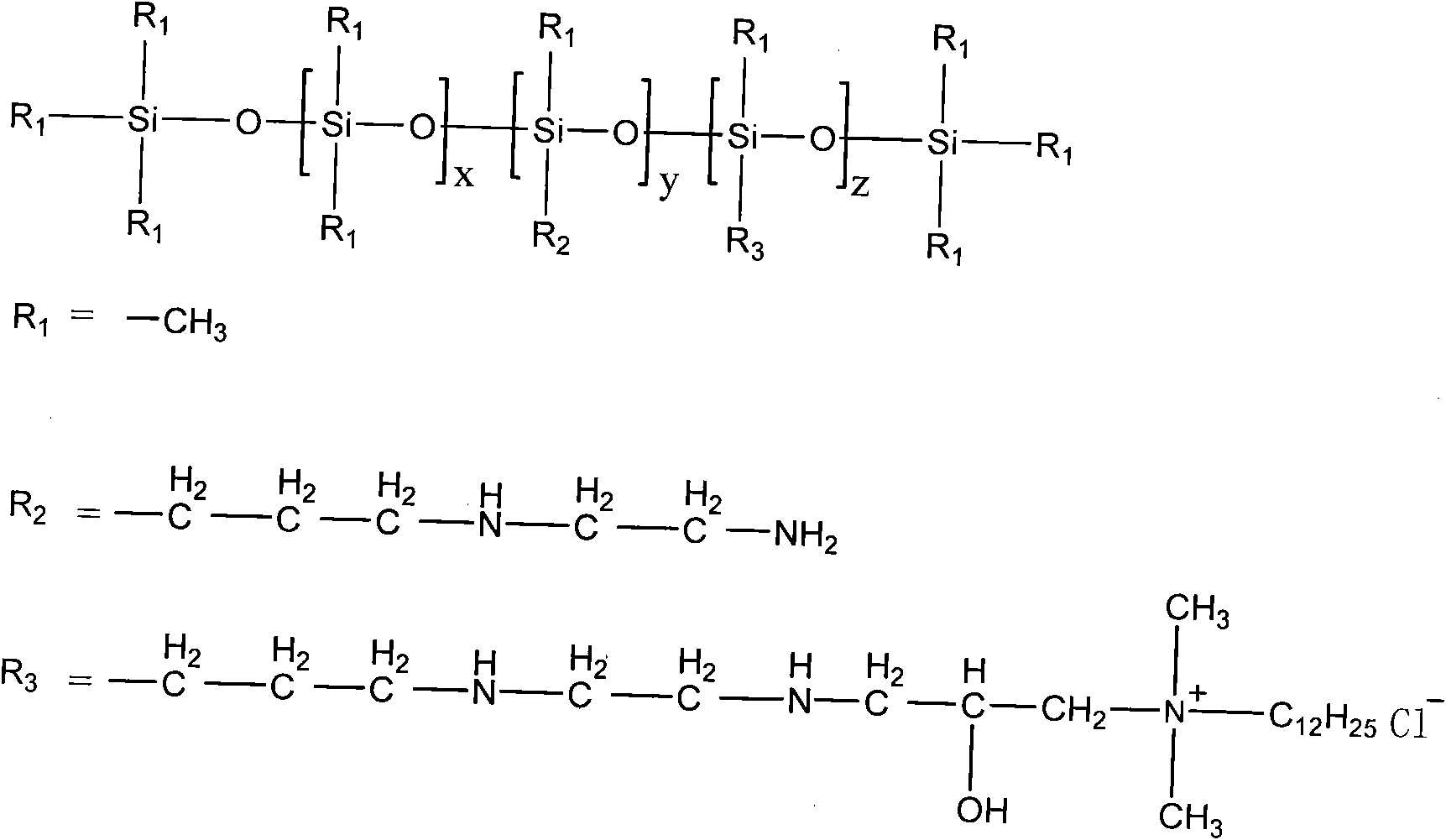

Quaternized modified amino silicone oil softener and preparation and application thereof

A technology of quaternary ammonium modification and amino silicone oil, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of poor whiteness, water absorption and easy decontamination, fabric oil spots, easy demulsification, etc. Achieve the effects of good storage and transportation stability, poor emulsion stability improvement, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

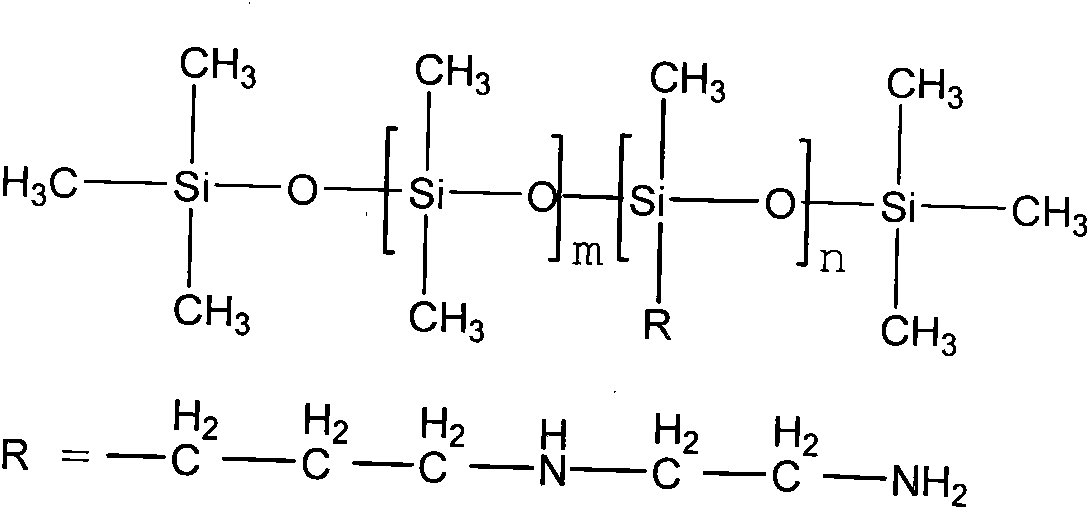

Embodiment 1

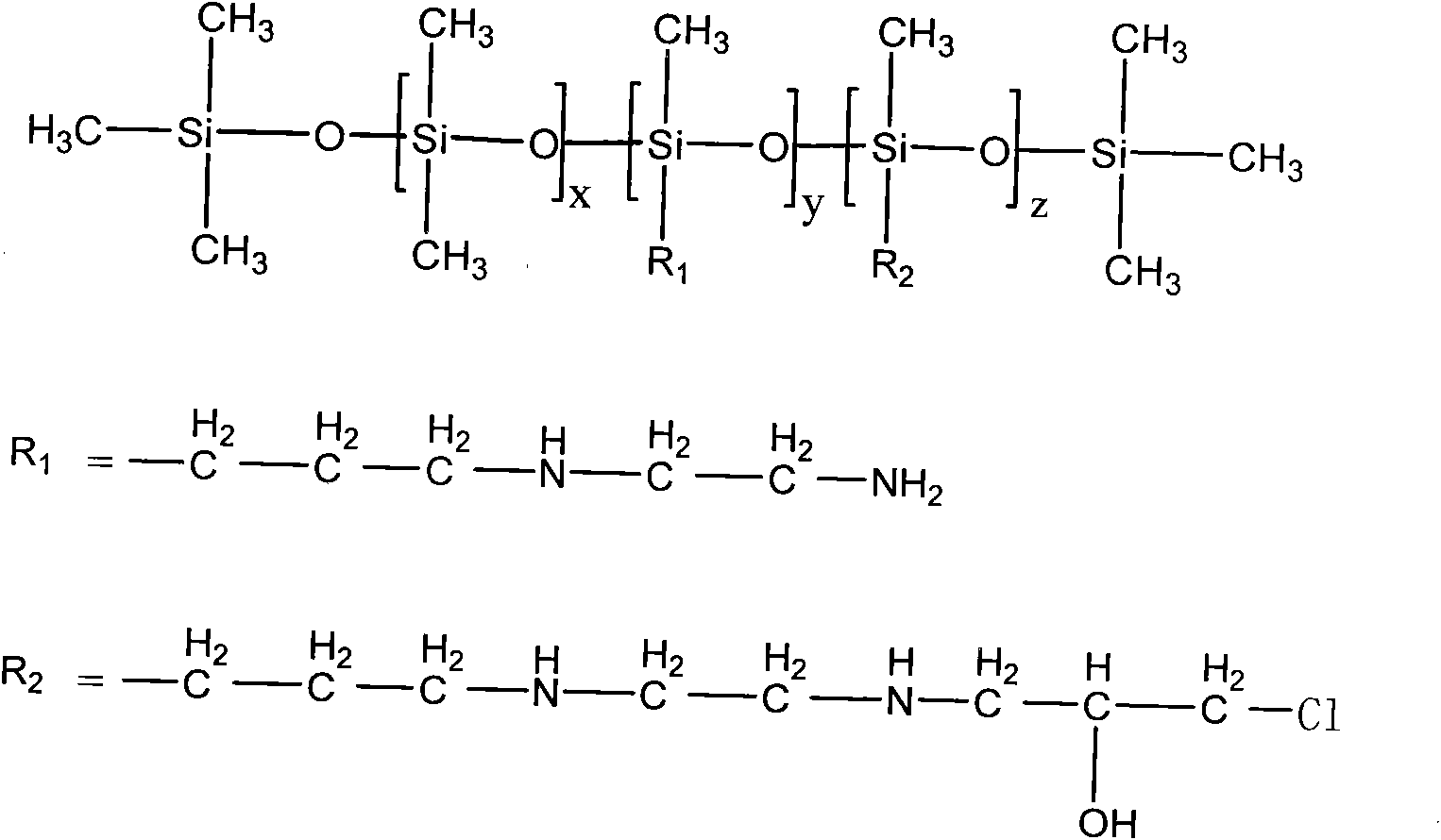

[0046] Add 300 g of octamethylcyclotetrasiloxane into a four-neck flask equipped with a condenser, a separatory funnel, a thermometer, and a nitrogen protection device. Use a constant pressure dropping funnel to drop 28g of coupling agent N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane into the four-necked flask, and add 0.85g of tetramethylhydrogen after 1h ammonium oxide catalyst. After stirring and raising the temperature to 110° C. for 8 hours, 0.20 g of hexamethyldisiloxane was added. After continuing the reaction for 1 hour, the temperature was raised to 140° C. to decompose the catalyst. Then, lower the temperature to 60°C and distill under reduced pressure to remove low boilers to obtain transparent and viscous amino silicone oil.

[0047] Dissolve 30 g of epichlorohydrin in 50 g of isopropanol, and drop it into a four-necked flask containing 100 g of amino silicone oil (ammonia value: 0.907 mmol / g) using a dropping funnel. Protected by nitrogen, the temperature...

Embodiment 2

[0050] Add 300 g of octamethylcyclotetrasiloxane into a four-neck flask equipped with a condenser, a separatory funnel, a thermometer, and a nitrogen protection device. Use a constant pressure dropping funnel to drop 25g of coupling agent N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane into the four-necked flask, and add 0.85g of tetramethylhydrogen after 1h ammonium oxide catalyst. After stirring and raising the temperature to 110°C for 10 hours, 0.20 g of hexamethyldisiloxane was added. After continuing the reaction for 1 hour, the temperature was raised to 140° C. to decompose the catalyst. Then, lower the temperature to 70°C and distill under reduced pressure to remove low boilers to obtain transparent and viscous amino silicone oil.

[0051] Dissolve 20 g of epichlorohydrin in 50 g of isopropanol, and drop it into a four-necked flask filled with 100 g of amino silicone oil (ammonia value: 0.907 mmol / g) using a dropping funnel. Protected by nitrogen, the temperature...

Embodiment 3

[0054] Weigh 30g of quaternized modified amino silicone oil, add quaternized modified amino silicone oil and 10g of deionized water into the container, stir and mix evenly, add dropwise a mixture of 2g of glacial acetic acid and 58g of deionized water, stir at high speed for 20-30min , to obtain a milky white appearance and a modified amino silicone oil emulsion with a solid content of 30%.

[0055] For the application of quaternized modified amino silicone oil softener, the padding process example: the amount of quaternized modified amino silicone oil softener emulsion (30% solid content) is 20g / L; the process flow is: one dipping and one rolling (Residue rate 80%)——drying (100°C, 90s)——baking (150°C, 60s).

[0056] After sorting, the determination of hydrophilicity shall refer to the AATCC Test Method 79-2000 standard, the whiteness test shall refer to GB / T8424.2-2001 the instrumental evaluation method for relative whiteness of textile color fastness test, and the breaking s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com