Gas ignition piezoelectric ceramics and manufacture process thereof

A piezoelectric ceramic and gas technology, which is applied in the field of gas ignition piezoelectric ceramics and its production process, and achieves the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is achieved by the following schemes.

[0021] A gas-ignited piezoelectric ceramic, containing main ingredients: lead oxide (PbO), zirconium dioxide (ZrO 2 ), titanium dioxide (TiO 2 ), barium oxide (BaO) and trace addition raw material; It is characterized in that: described trace addition raw material is cerium oxide (CeO 2 ), antimony trioxide (Sb 2 o 3 ) and manganese dioxide (MnO 2 );

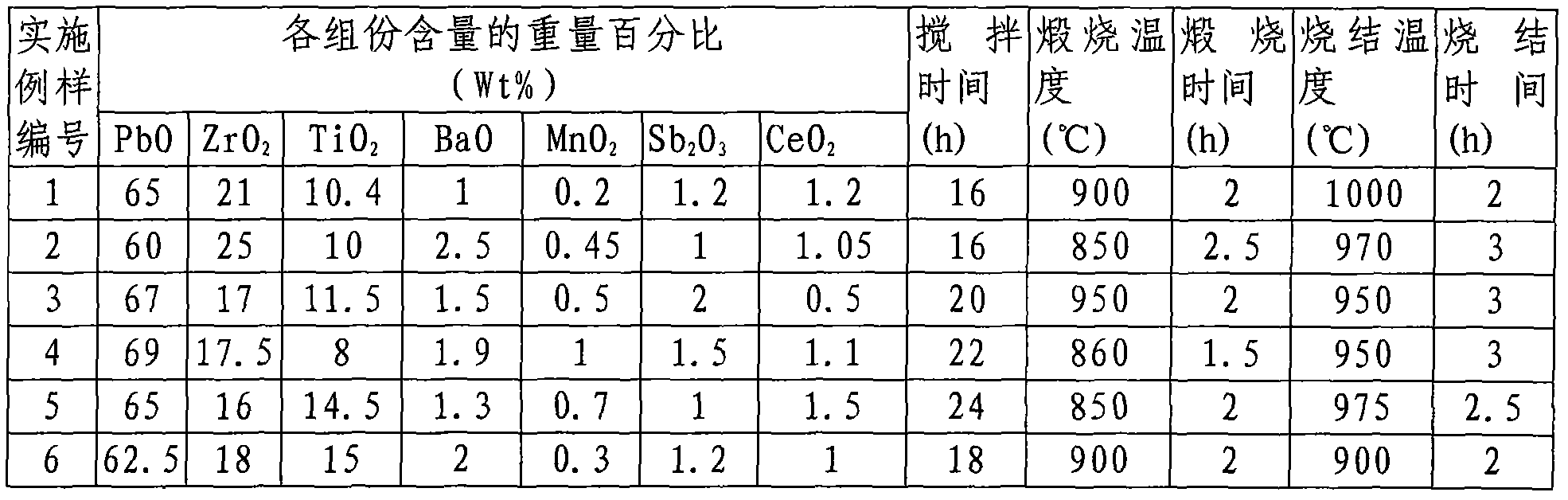

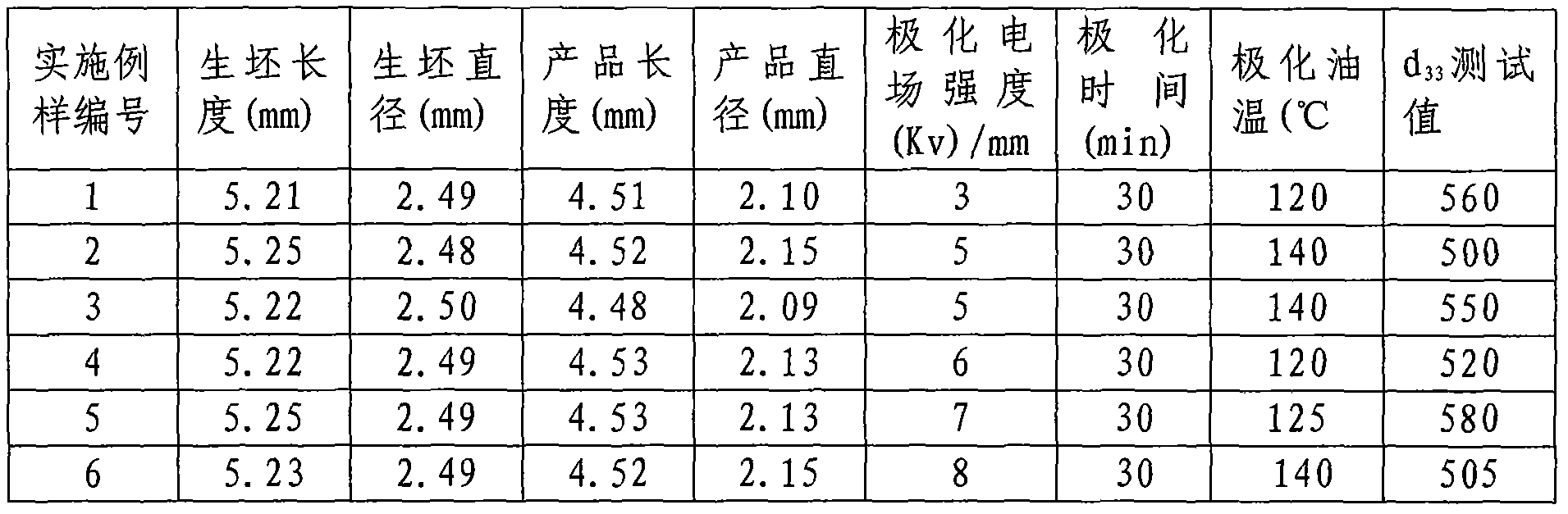

[0022] According to the ratio of the main component raw materials and the trace addition raw materials and the production method, Table 1 lists the data of the sintering temperature and time of the ignition piezoelectric ceramics for each example under different proportions of ingredients. Table 2 gives the piezoelectric performance parameters of each example.

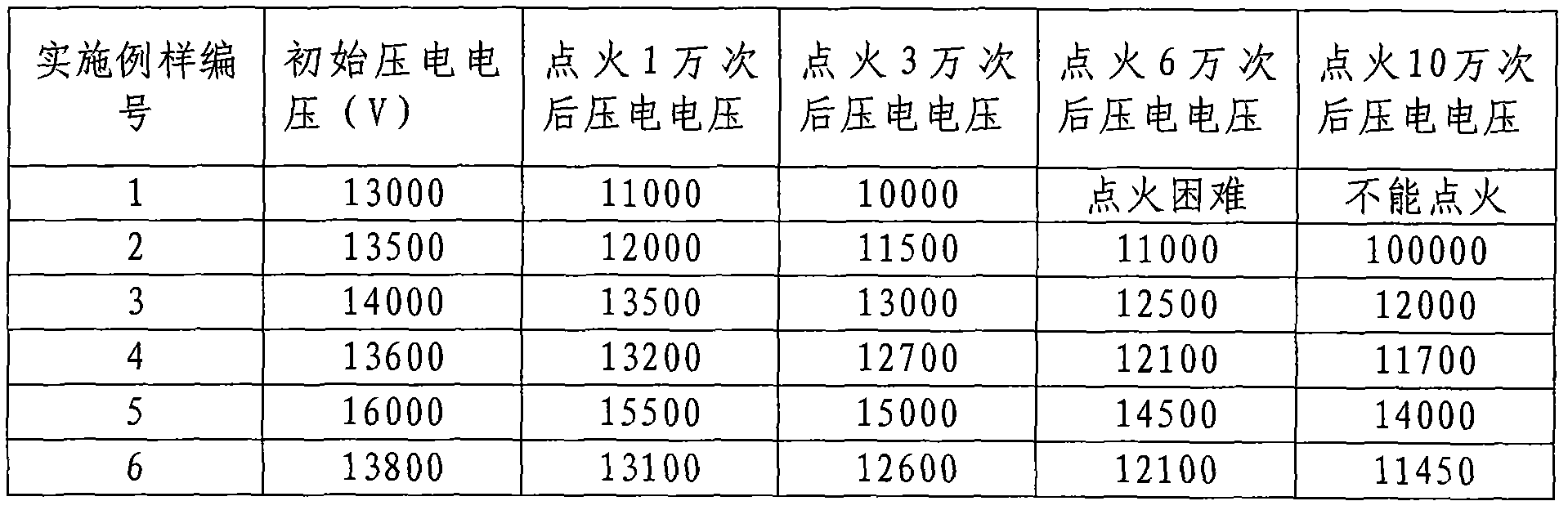

[0023] Table 3 lists the different formulas of each example sample, the actual installation in the daily lighter sample device, and the number of test ignitions. Except for No. 1 formula, which cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com