Method for preparing iron-lithium phosphate by using high-purity magnet fine mineral powder as iron source

A technology of magnetite concentrate and lithium iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as hindering large-scale application, high cost of lithium iron phosphate, etc., and achieve product performance consistency High, high rate cycle performance, low control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 10Kg of high-purity magnetite concentrate powder with a purity of 99% and an average particle size of about 100 um into a ball mill for primary grinding, and grind for 8 hours to obtain primary ground powder with an average particle size of about 15 um. Then add the primary grinding powder to the high-energy ball mill, and after ball milling for 8 hours, an ultra-fine high-purity magnetite concentrate powder with an average particle size of about 0.8um is obtained.

[0033] (2) Add 10Kg ultrafine high-purity magnetite concentrate powder, 13.4Kg purity of 99.6% lithium dihydrogen phosphate, 3.4Kg purity of 99.6% glucose monohydrate, 107.1Kg deionized water in the ball mill, and ball mill for 5 hours.

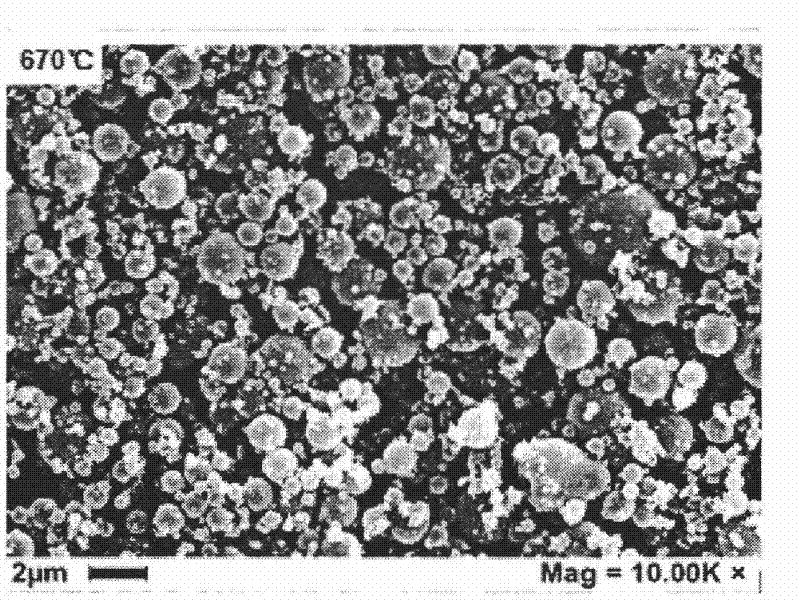

[0034] (3) Use a centrifugal spray drying granulator to dry and granulate the slurry after ball milling to obtain a lithium iron phosphate precursor with an average particle size of about 2 μm.

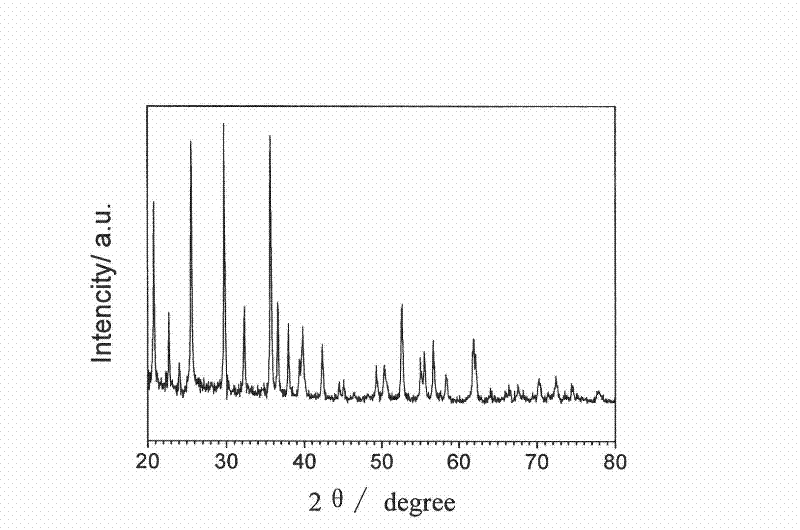

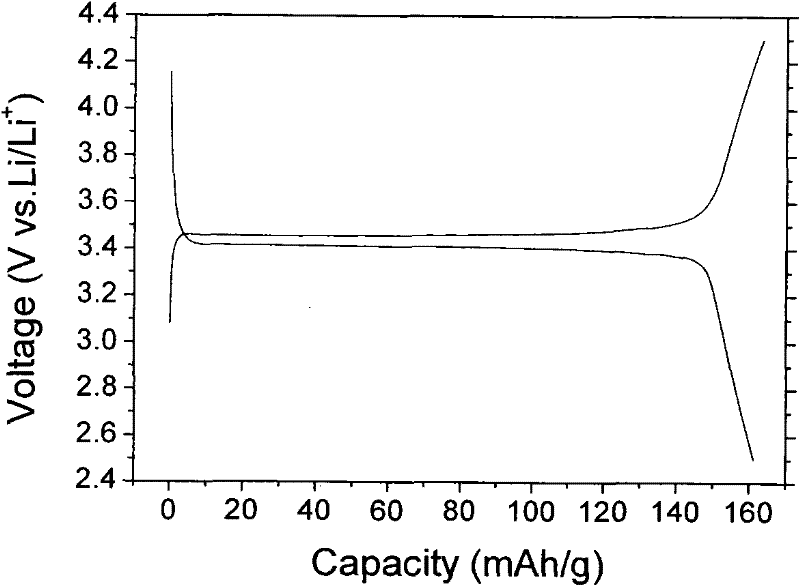

[0035] (4) Put the lithium iron phosphate precursor into a pusher kil...

Embodiment 2

[0037] (1) Add 10Kg of high-purity magnetite concentrate powder with a purity of 99% and an average particle size of about 100 um into a ball mill for primary grinding, and grind for 5 hours to obtain primary ground powder with an average particle size of about 20 um. Then add the primary grinding powder into the high-energy ball mill, and after ball milling for 5 hours, an ultra-fine high-purity magnetite concentrate powder with an average particle size of about 1.5um is obtained.

[0038] (2) Adding 10Kg ultrafine high-purity magnetite concentrate powder, 14.9Kg purity is 99% ammonium dihydrogen phosphate, 5.5Kg purity is 99.5% lithium hydroxide, 3.4Kg purity is 99.6% glucose monohydrate in ball mill , 135.2Kg deionized water, ball milled for 3 hours.

[0039] (3) Use a centrifugal spray drying granulator to dry and granulate the slurry after ball milling to obtain a lithium iron phosphate precursor with an average particle size of about 5 μm.

[0040] (4) Put the lithium i...

Embodiment 3

[0042] (1) Add 10Kg of high-purity magnetite concentrate powder with a purity of 99% and an average particle size of about 100 um into a ball mill for primary grinding, and grind for 8 hours to obtain primary ground powder with an average particle size of about 15 um. Then add the primary grinding powder to the high-energy ball mill, and after ball milling for 8 hours, an ultra-fine high-purity magnetite concentrate powder with an average particle size of about 0.8um is obtained.

[0043] (2) Add 10Kg ultra-fine high-purity magnetite concentrate powder, 13.4Kg purity of 99.6% lithium dihydrogen phosphate, 2.9Kg purity of 99.8% fructose, 107.1Kg deionized water in the ball mill, and ball mill for 5 hours.

[0044] (3) Use a centrifugal spray drying granulator to dry and granulate the slurry after ball milling to obtain a lithium iron phosphate precursor with an average particle size of about 5 μm.

[0045](4) Put the lithium iron phosphate precursor into a pusher kiln under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com