Control method of expansion degree of fired coal for binderless briquettes

A binder-free, control-based technology, applied in coke ovens, petroleum industries, etc., can solve problems that affect the normal production, safety and longevity of coke ovens, increase the expansion of coal into the furnace, damage the furnace wall, etc., and achieve improved coke The effect of improving quality and bulk density and stabilizing coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

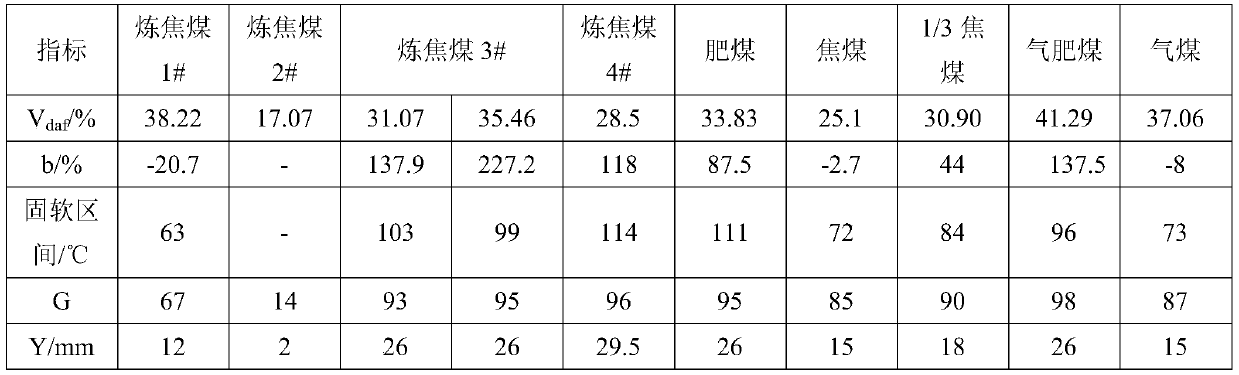

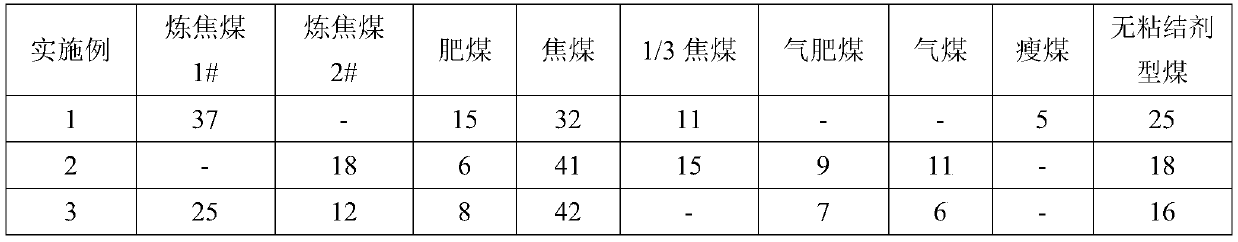

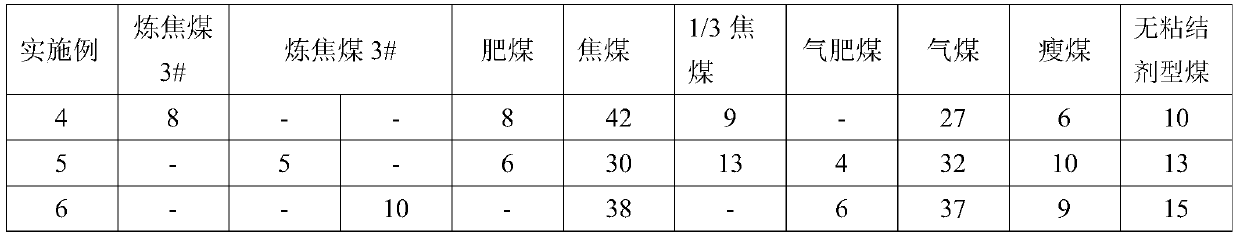

[0018] The invention discloses a method for controlling the expansion degree of furnace coal without binder briquettes. The control method adjusts the composition of each coal blend according to the mass percentage of the binder-free briquette in the total amount of furnace coal, and reduces the input cost. The degree of expansion of furnace coal comprises the following control steps:

[0019] 1) Measure the mass percentage of the total amount of furnace coal that is accounted for by binder-free briquettes; if the mass percentage of the total amount of furnace coal by no binder briquettes is greater than 15%, proceed to the following step 2a); if no binder briquettes account for The mass percentage of the total amount of coal put into the furnace is less than or equal to 15%, and directly proceed to the following step 2b); 2a) increase the mass percentage content of coking coal with high volatile content, low expansion degree or no expansion degree, and low solid-soft interval;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com