Wo2010007950

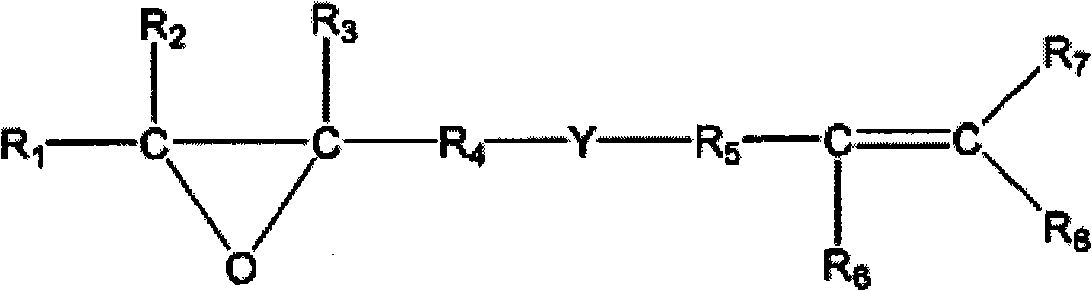

一种热塑性树脂、耐化学性的技术,应用在环氧-基添加剂领域,能够解决低熔体强度、很难可挤出性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

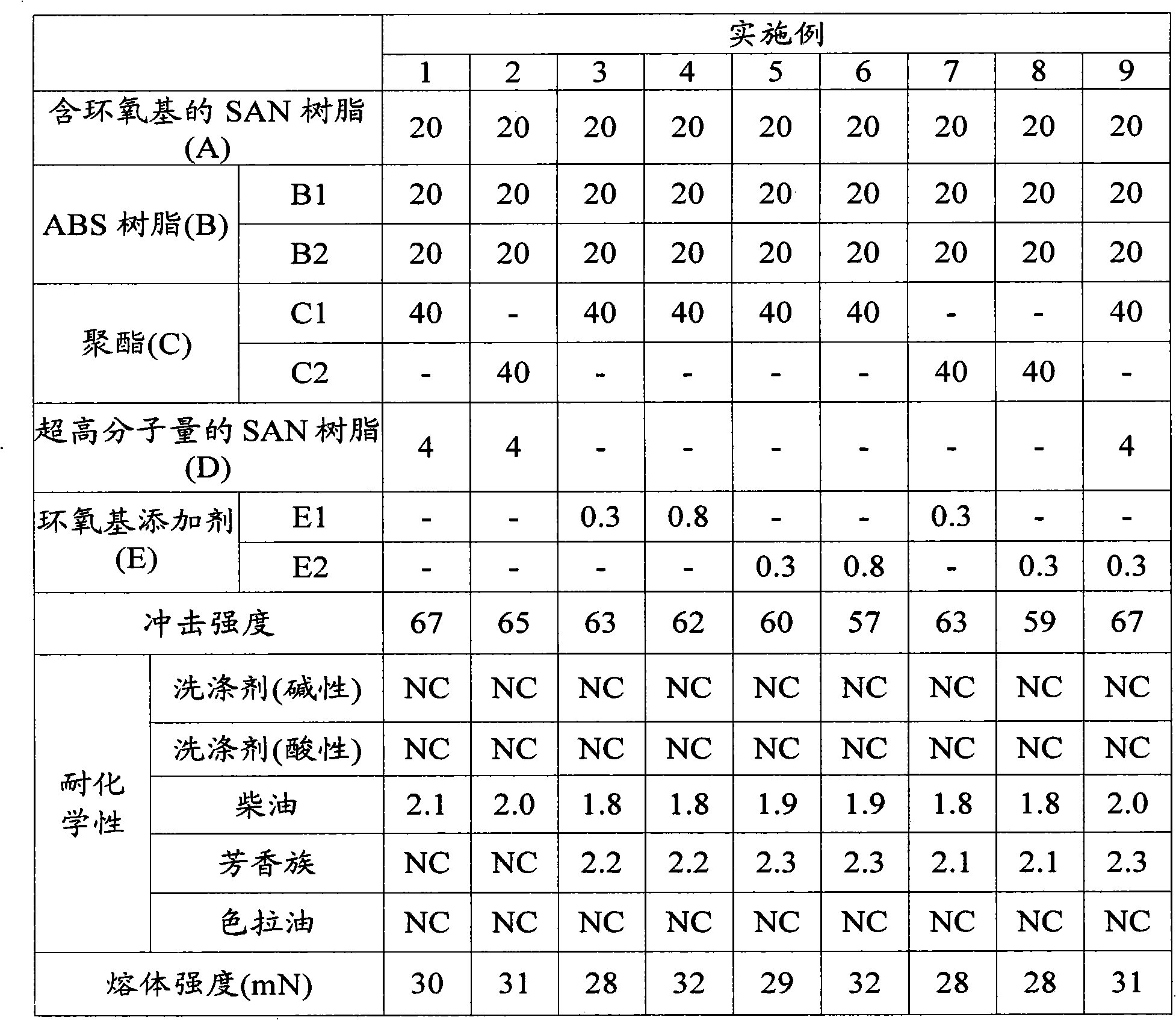

Embodiment 1~9 and comparative example 1~6

[0116]The components shown in Table 1 and 0.3 parts by weight of a hydroxyphenyl antioxidant were mixed in a Hansel mixer for 3 to 10 minutes to prepare a mixture. The mixture is fed into a conventional twin-screw extruder at a rate of 30-60 kg / h, and heated at 180-280° C.

[0117] screw speed in rpm to extrude into pellets. Melt strength was measured after the resin pellets were dried at 100°C for 3 hours. Subsequently, the resin pellets were molded into test samples using a 6-oz injection molding machine at 180-280°C with a barrel temperature of 40-80°C. The physical properties and chemical resistance of the test samples were measured after placing the samples at 23°C and 50% relative humidity for 40 hours.

[0118] (1) Impact strength: According to ASTM-D256, measure the Izod impact strength with a sample with a thickness of 1 / 8″. The final test result (kgf·cm / cm) is obtained by calculating the average value of 5 test results.

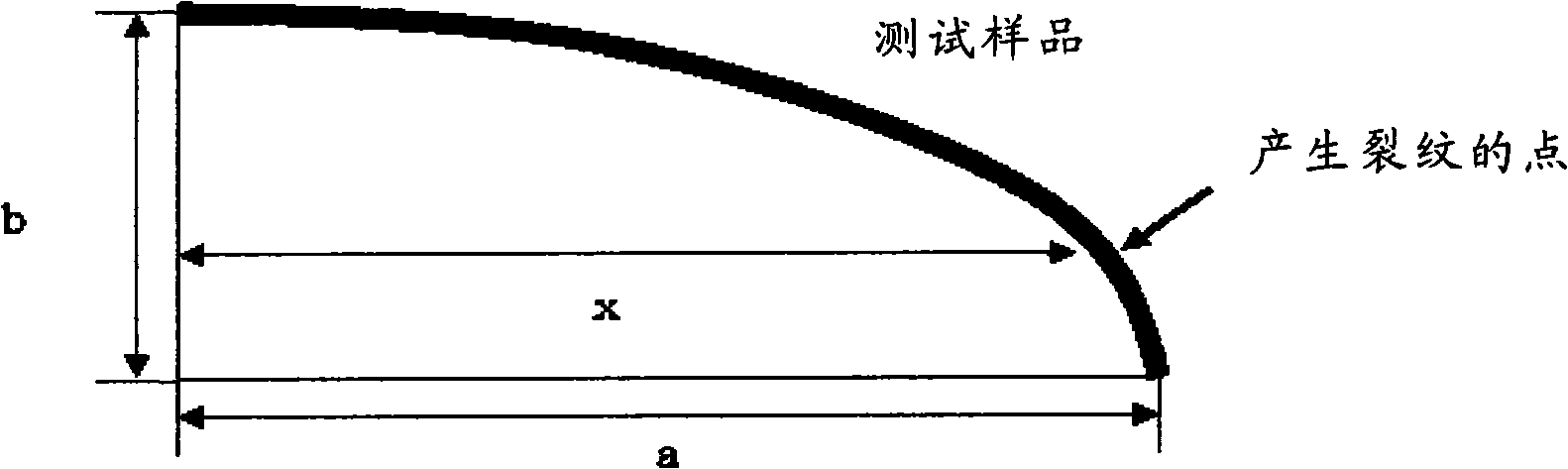

[0119] (2) Chemical resistance: In order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com