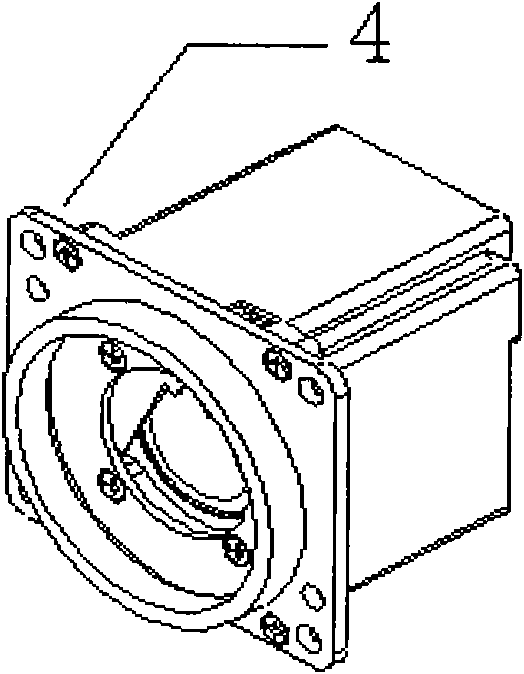

Infrared and glimmer multispectral fusion front end optical-mechanic structure

A pre-fusion, multi-spectral technology, applied in optics, optical components, instruments, etc., can solve the problems of optical signal attenuation, difficult transmittance, high parallel precision requirements, etc., to achieve convenient operation and use, avoid manufacturing process, and improve coincidence degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Invention principle:

[0021] 1. Binocular imaging system theory

[0022] The infrared imaging system and the low-light imaging system can be regarded as a binocular imaging system. The binocular imaging can obtain two images of the same scene with different viewpoints. The binocular imaging model can be regarded as a combination of two monocular imaging models. made. In actual imaging, the two monocular imaging can be realized by collecting two monocular systems at the same time, and can also be realized by one monocular system collecting separately in two poses (at this time, it is generally assumed that the subject and the light source do not move and change ).

[0023] According to the existing conditions, in our final front-end optical system design, we adopted such as figure 2 The design of parallel optical axes shown, under the existing technical conditions, this design is guaranteed both in terms of process and imaging quality. The lens field of view of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com