Manufacturing method of metal woven screen

A manufacturing method and metal weaving technology, which is applied in the field of screen mesh manufacturing, can solve the problems of increasing the difficulty of the pre-bending process, poor versatility, and fracture, and achieve the effects of increased hardness, uniform heating temperature, and reduced use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First of all, according to the specifications and materials required by the screen, buy the corresponding carbon steel wire or alloy steel wire from the market. If it is a cooked wire (a steel wire that has been heat treated and tempered before leaving the factory), it can be directly used for embossing wheels. The steel wire is pressed and pre-bent, such as figure 1 Shown.

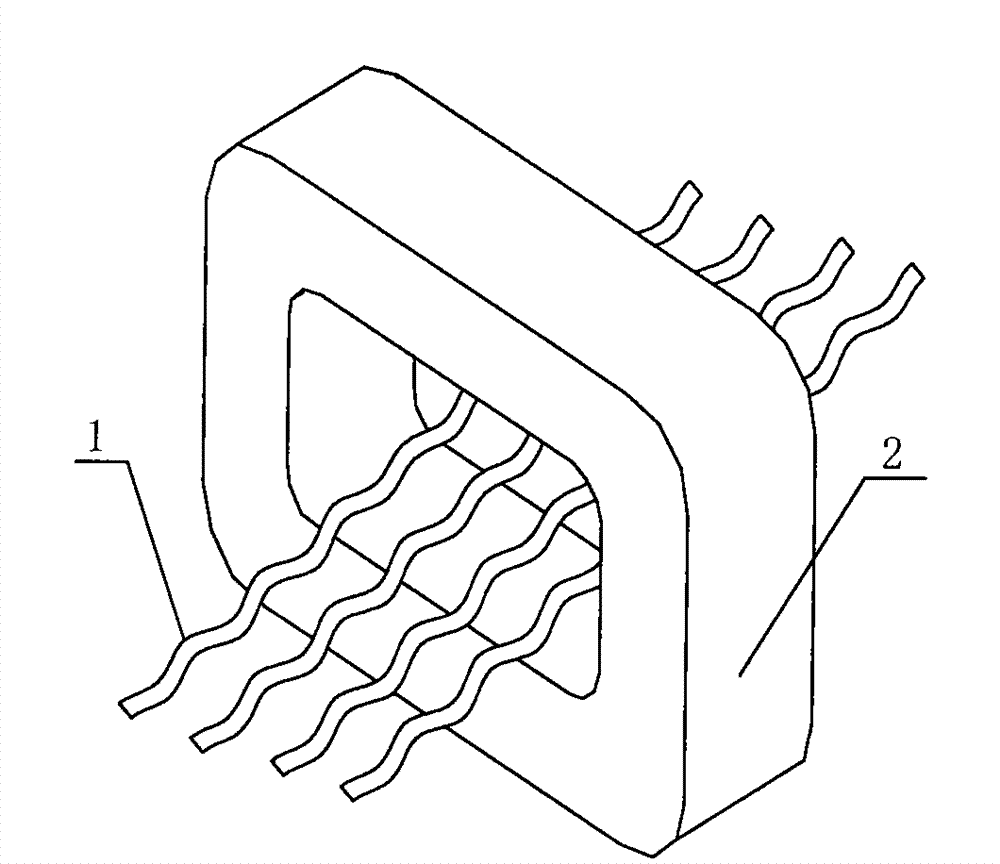

[0019] Then the steel wire is heat treated. Due to the large size of the screen, the length of each steel wire is generally more than 10 meters. Therefore, the present invention uses induction heating to quench the steel wire, so that the steel wire can be continuously passed through the intermediate frequency or high frequency induction heating coil. Heating, adjust the heating power and the speed of the steel wire to reach the required temperature, and then quickly cool for quenching. The invention adopts this intermediate frequency or high frequency quenching method. On the one hand, very long ste...

Embodiment 2

[0022] First, press and pre-bend the purchased steel wire. After pre-bending, the steel wire is then tempered at low temperature to eliminate stress.

[0023] Then, in the same manner as in Example 1, the pre-bent steel wire is subjected to intermediate frequency or high frequency quenching, and then a tempering treatment is performed to make the hardness of the steel wire reach about HRC48.

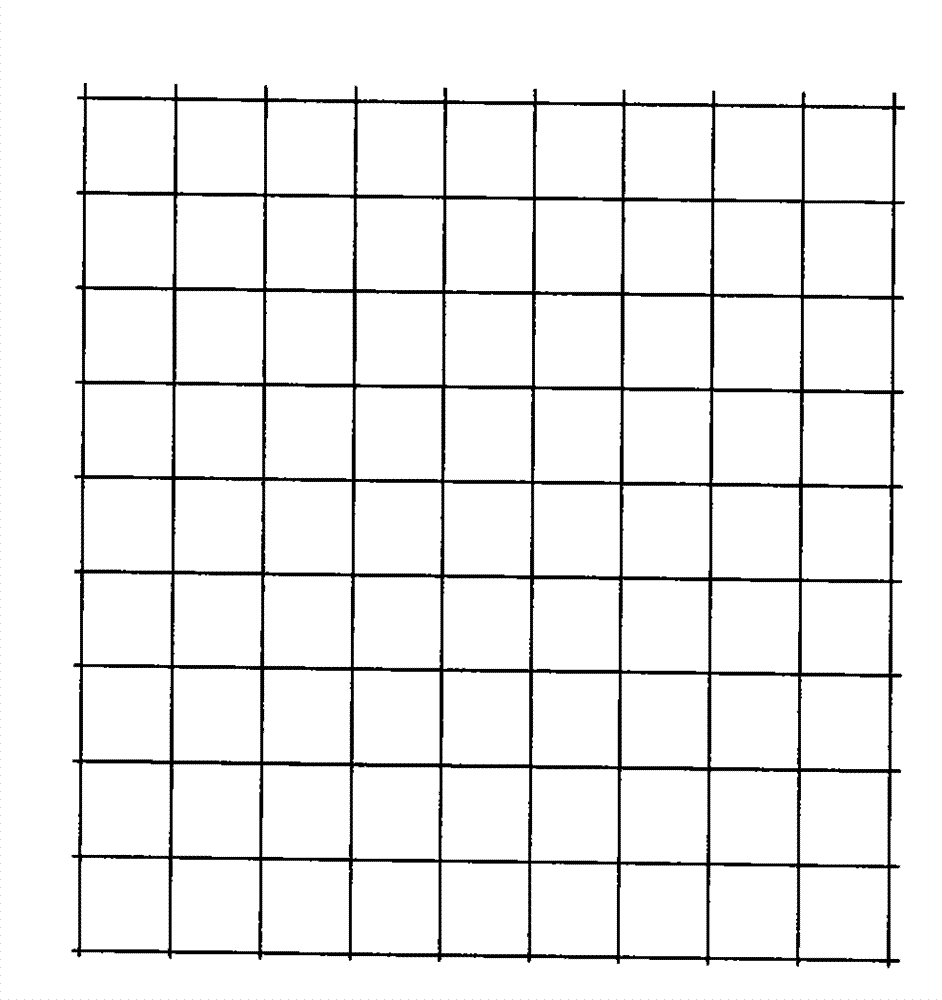

[0024] Finally weave into a screen.

Embodiment 3

[0026] First of all, if the steel wire you buy is raw wire (a steel wire that has not been heat-treated and tempered before leaving the factory), it needs to be annealed to eliminate the stress, and then pre-bended, so as to avoid breakage during pre-bending. After pre-bending, the steel wire is then tempered at low temperature to eliminate stress, which can avoid cracking during subsequent heat treatment.

[0027] Then, in the same manner as in Example 1, the pre-bent steel wire is subjected to intermediate frequency or high frequency quenching, and then a tempering treatment is performed to make the hardness of the steel wire reach about HRC50.

[0028] Finally weave into a screen.

[0029] The ordinary screens on the market now generally have a service life of less than one month in quarries. The service life of the screen made by the method of the present invention can reach 2.5-4 times that of the ordinary screen. According to different application requirements and process req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com