Proton exchange membrane and preparation method thereof

A proton exchange membrane and thin film technology, applied in the field of proton exchange membrane and its preparation, can solve the problems of high production difficulty, small grafting reaction area, unsuitable for industrial production, etc., and achieves good dimensional stability, uniform monomer distribution, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

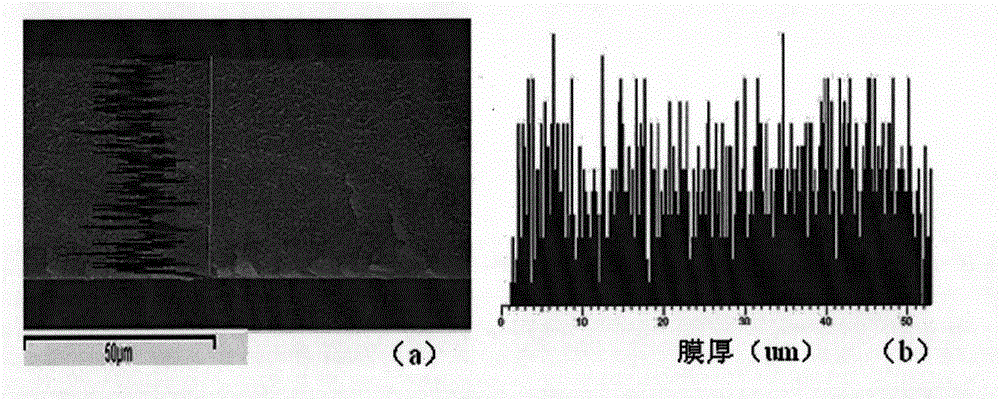

Embodiment 1

[0039] Weigh 20 grams of polyvinylidene fluoride (number-average molecular weight: 1 million) (PVDF) particles with an electronic balance, and the particle size is 0.1 mm. Irradiate to 10 kGy in air using a cobalt 60 gamma ray source. Put the irradiated powder into a 200ml Erlenmeyer flask, add 80ml deionized water and 10ml styrene in sequence. The system was ventilated with nitrogen for 20 minutes to remove oxygen, then sealed, and placed in a water bath at 60°C for 5 hours under magnetic stirring. After the reaction, the grafted polyvinylidene fluoride powder was obtained by filtration, and the grafting rate was measured to be 20% after extraction and drying with cyclohexane. Weigh 5 grams of polyvinylidene fluoride after grafting, dissolve it in 150ml N-methyl-2-pyrrolidone (NMP), and after the solution is uniformly clarified, scrape it on a glass plate with a coater to form a film, and put it in an oven Dry at 60°C for 8 hours to evaporate the solvent, and the film thick...

Embodiment 2

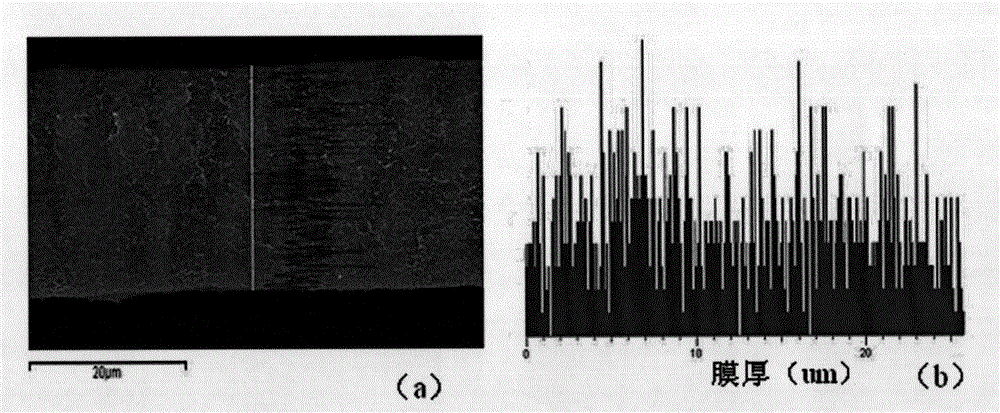

[0041] Weigh 150 grams of polyvinylidene fluoride (1 million number average molecular weight) (PVDF) powder with an electronic balance, with a particle size of 0.1 mm, and irradiate it to 15 kGy with an electron beam in nitrogen. Put the irradiated powder into a 500 ml three-neck flask, add 200 ml deionized water, and 80 ml α, β, β-trifluorostyrene monomer. Under the action of mechanical stirring at 120 revolutions per minute, after passing nitrogen for 10 minutes, the reaction system was heated to 80 degrees with an oil bath, and reacted for 6 hours. During the reaction, the flow rate of nitrogen was kept constant. After the reaction, the stirring was stopped, and the grafted polyvinylidene fluoride powder was obtained by filtration after cooling the system, and the grafting rate was measured to be 8% after extraction and drying with toluene. Weigh 15 grams of grafted polyvinylidene fluoride, and hot-press to form a film on a flat vulcanizing machine at a temperature of 250 d...

Embodiment 3

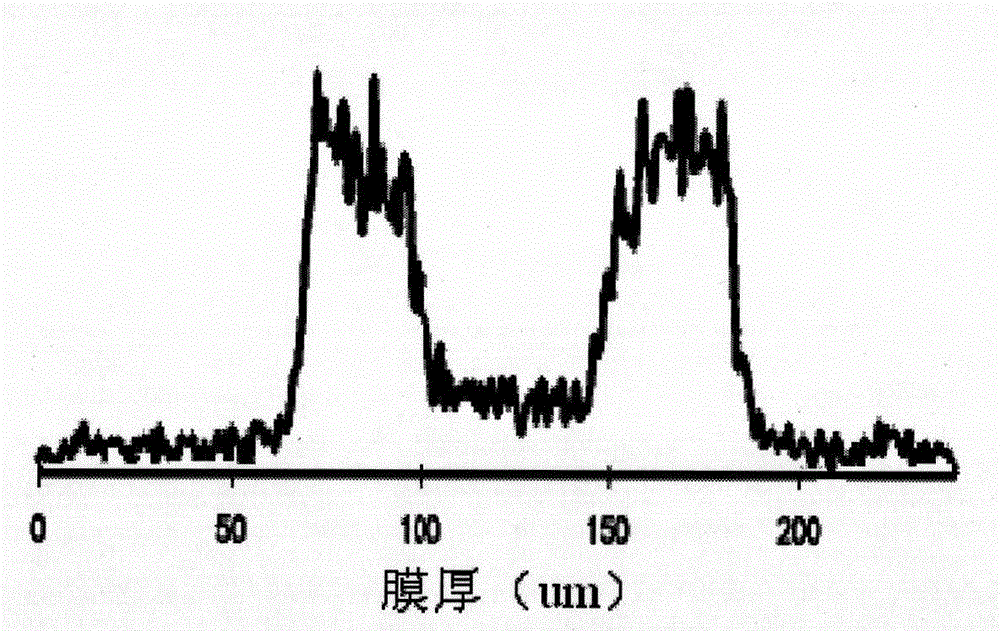

[0043] Weigh 2 kg of polyvinylidene fluoride (1 million number average molecular weight) (PVDF) powder with a particle size of 0.5 mm with an electronic balance, and irradiate to 20 kGy in air with a cobalt 60 gamma ray source. Put the irradiated powder into a 5-liter reactor, and add 3 liters of deionized water and 400 milliliters of p-methylstyrene in sequence. Under the action of mechanical stirring at 200rmp per minute, first vacuumize for 5 minutes, and then pass nitrogen gas to remove oxygen for 5 minutes. After three cycles, pass circulating hot water into the heating jacket to heat the reaction system to 85 degrees Celsius, and react for 6 hours. The nitrogen flow was maintained constant during the reaction. After the reaction, stop stirring, filter to obtain polyvinylidene fluoride powder after grafting, wash with cyclohexane after drying for many times to remove homopolymer, dry with hot air flow to remove cyclohexane, and the grafting rate is 15%. . Weigh 500 gram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com