Preparation method of semiconductor chip

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increased electron migration, high cost, and failure of electron migration test, so as to reduce the path and reduce the probability of occurrence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In view of the fact that the other steps of the semiconductor manufacturing method of the present invention are basically the same as the steps of the existing semiconductor chip manufacturing method, and these steps are not the invention point of the present invention, so other steps of the semiconductor manufacturing method (such as long Steps such as crystallization, cutting, etc.) are described in detail one by one, but only some main necessary steps in the semiconductor manufacturing method are listed.

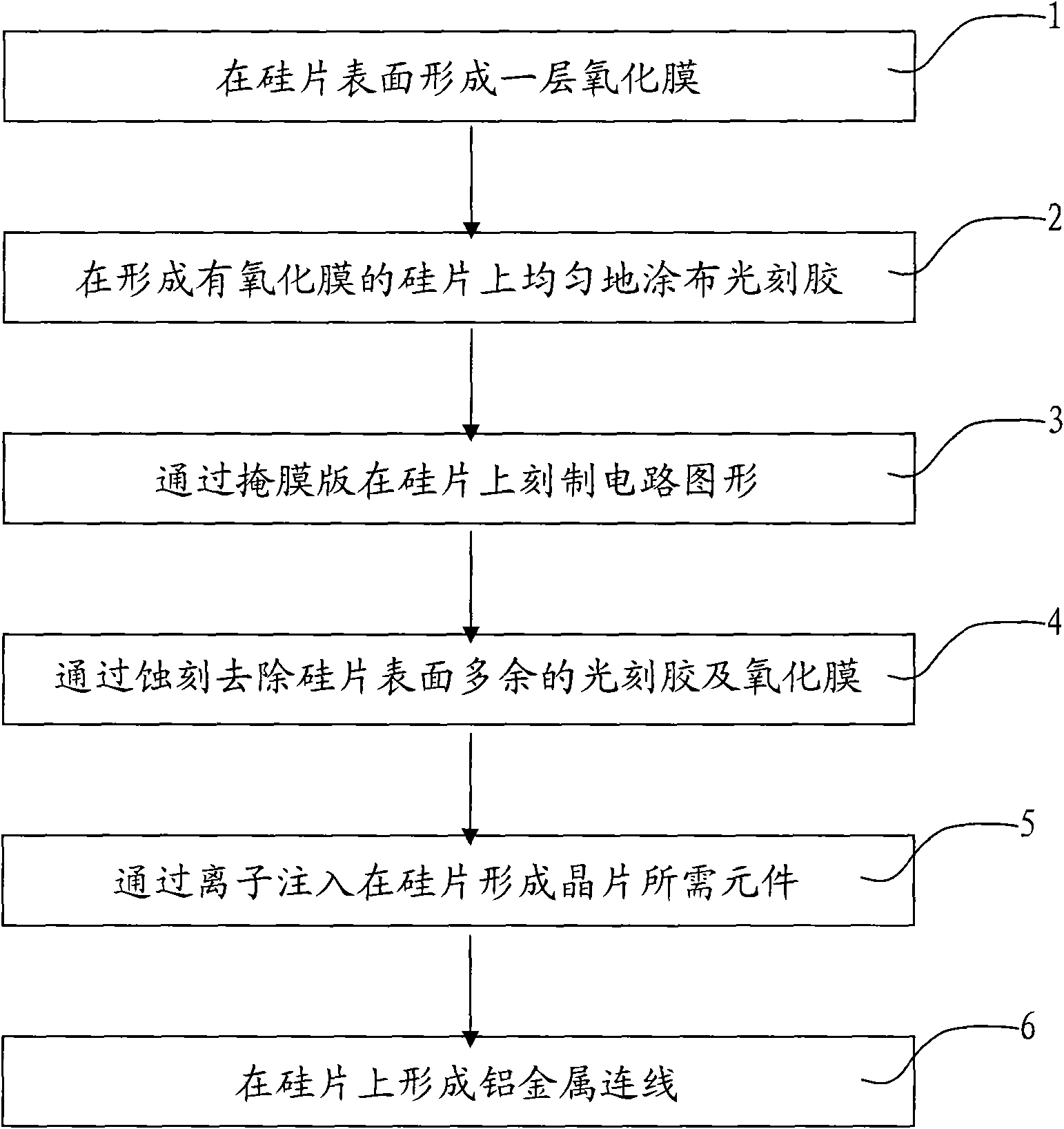

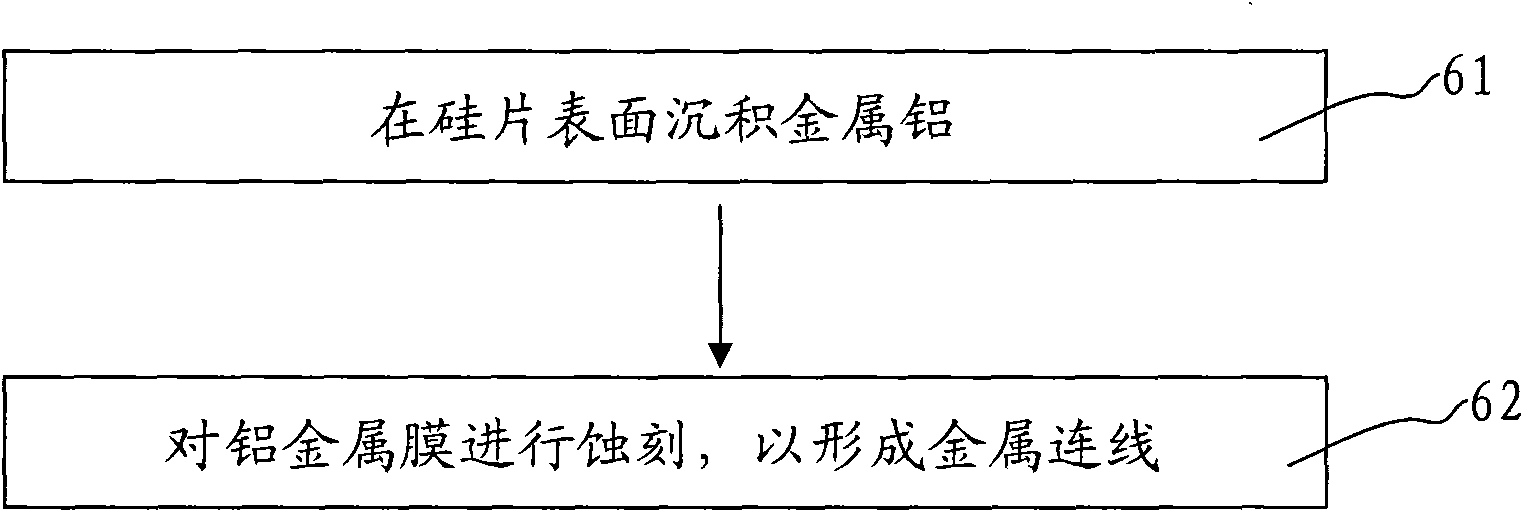

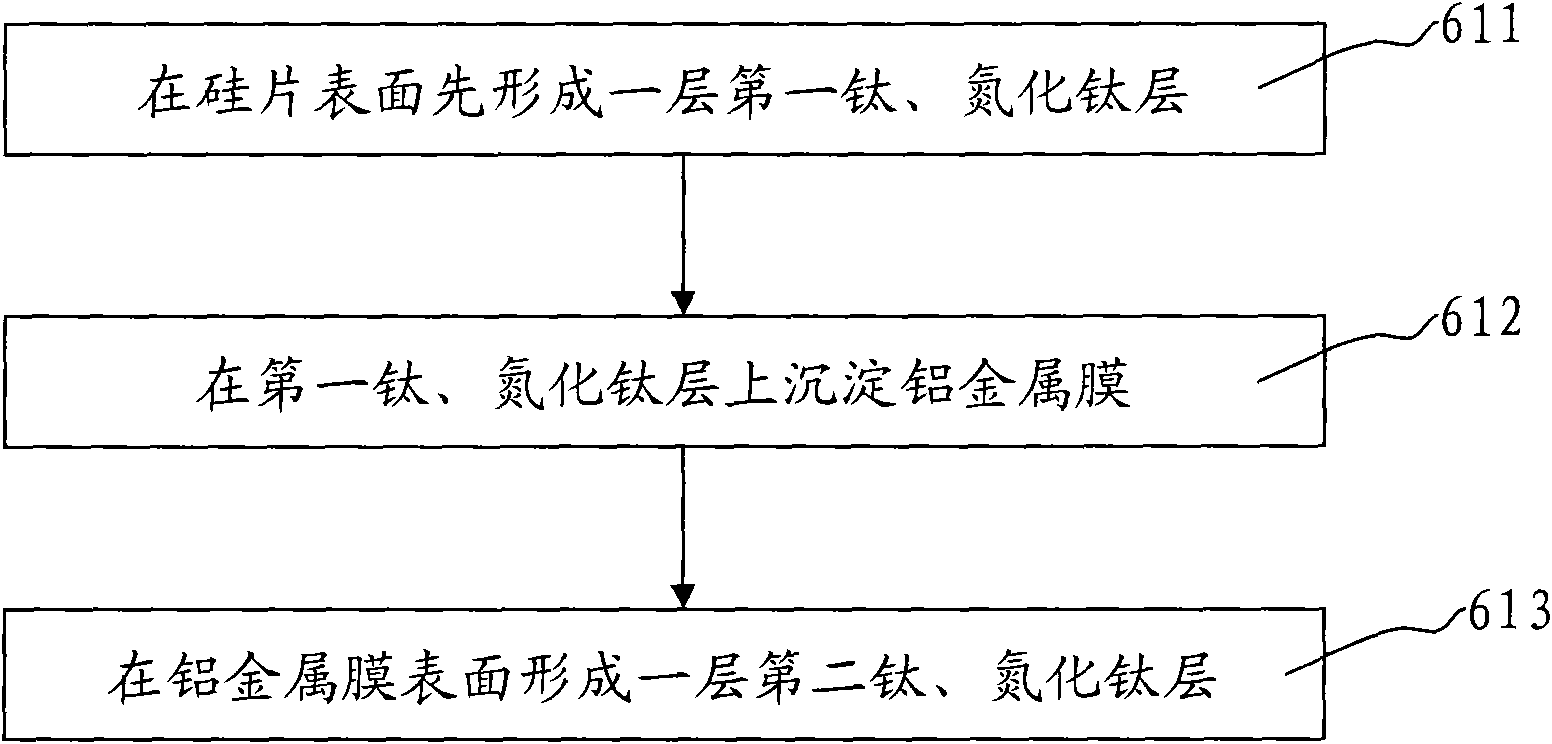

[0019] see figure 1 As shown, it shows a flow chart of the semiconductor chip manufacturing method of the present invention. As shown in the figure, a semiconductor chip manufacturing method of the present invention includes the following steps:

[0020] Step 1: a step of first forming a uniform thin oxide film on the surface of the silicon wafer;

[0021] Step 2: then uniformly coating a photoresist on the silicon wafer formed with an oxide film to make the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com