Method for preparing high-purity corrosion-resistant aluminum coating on titanium alloy component

A titanium alloy and aluminum coating technology, which is applied in the field of titanium alloy parts processing, can solve the problem that the thickness, bonding force, density and coating temperature cannot meet the comprehensive performance requirements of the coating layer of titanium alloy parts at the same time, and affect the coating and parts. Bonding properties, changes in the structure of titanium alloy parts, etc., to achieve the effects of enhanced bonding, reduced porosity and stress, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of method for preparing high-purity corrosion-resistant aluminum coating on titanium alloy parts, adopts high-power intermediate frequency magnetron sputtering equipment to carry out, and its concrete practice is:

[0024] A. Cleaning Put 800 pieces of titanium alloy parts after ultrasonic degreasing and drying in a vacuum chamber, use 99.9% pure aluminum as the target material, close the vacuum chamber, and when the vacuum is evacuated to 3.6×10~3Pa, pass in argon gas , so that the air pressure in the vacuum chamber reaches 1-2 Pa, turn on the bias power supply, apply a bias voltage of -1500V to the part, glow discharge to form argon plasma, and clean the part by argon plasma sputtering for 10 minutes; turn on the target power supply;

[0025] B. After the deposited aluminum coating is cleaned, adjust the argon pressure, the pressure is 0.5×10~1Pa--6×10~1Pa argon; add a negative bias of -200V to the part, turn on the target sputtering power supply,...

Embodiment 2~10

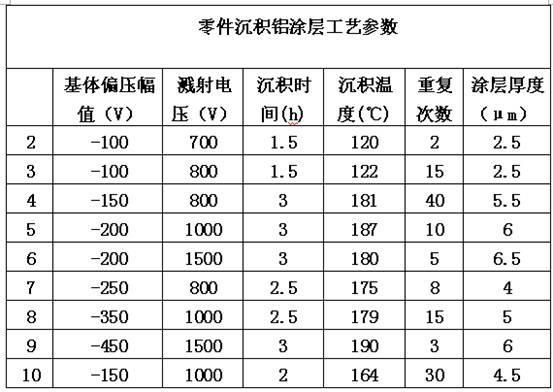

[0029] The methods of Examples 2-10 are basically the same as those of Example 1. The difference is that during the deposition of the aluminum coating, the bias voltage amplitude of the parts is set differently, the sputtering current and the deposition time are different, and the thickness obtained by deposition is different. Its specific values are shown in the table below:

[0030] The parameter setting of embodiment 2~10 deposited aluminum coating

[0031]

[0032] Note: The coating thickness is measured with a micrometer (0.001mm) at the part thread end 1cm away from the rod diameter, and the diameter of the rod before and after coating is measured, and then subtracted to obtain the average value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com