Method for preparing thermoplastic vulcanized rubber

A thermoplastic vulcanizate and equipment technology, applied in the field of thermoplastic vulcanizate preparation, can solve the problems of decreased elastic properties, reduced hardness and fluidity, and difficulty in uniform dispersion and extrusion of materials, so as to reduce equipment investment and production costs, improve Dispersion and performance, the effect of improving blending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

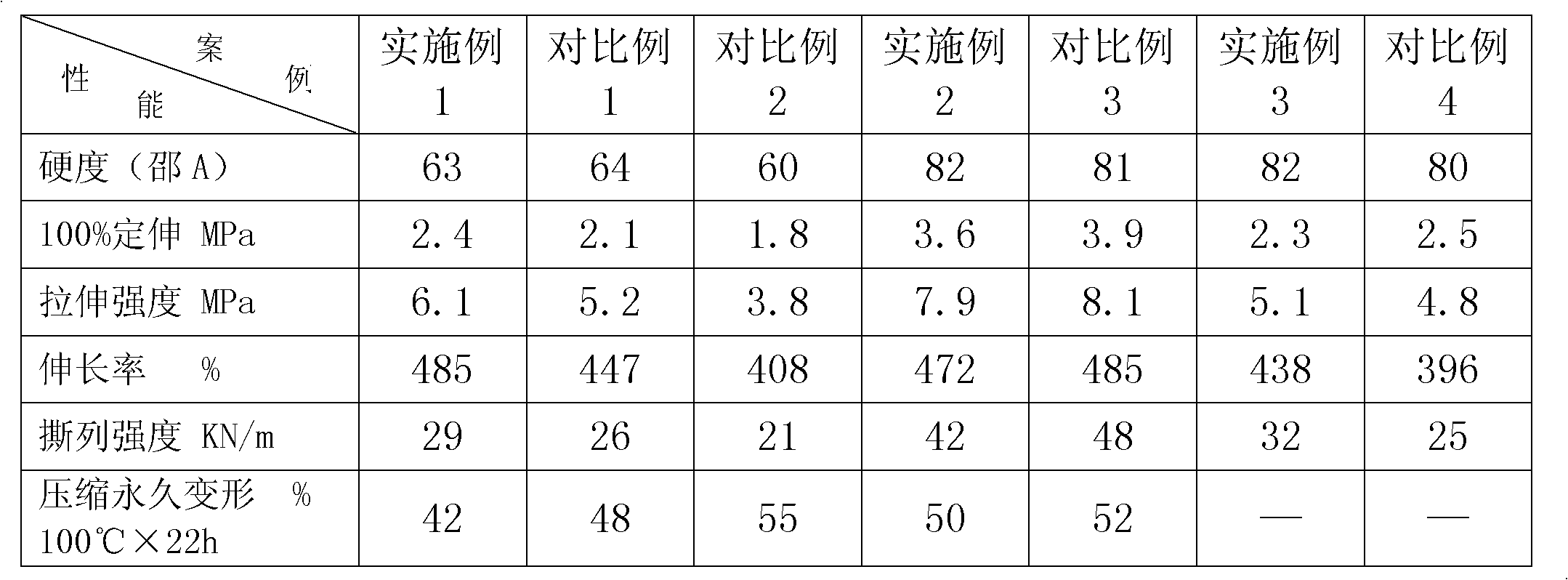

Embodiment 1

[0026] Utilize common rubber and plastic equipment including common internal mixer and heating temperature control system thereof, open mill, plastic crusher and plastic extruder, prepare the EPDM rubber / polypropylene (EPDM / polypropylene) of rubber-plastic ratio 80 / 20 PP) thermoplastic vulcanizate. The heating and temperature control system of the ordinary internal mixer in the ordinary rubber equipment is high-temperature heat transfer oil heating or steam heating, and the heating control temperature range is 100-220°C. In this embodiment, the model is ML-5L meshing type with intelligent control system The internal mixer heating and temperature control system is changed from hot water circulation heating to high-temperature heat conduction oil heating, so that the maximum heating control temperature of the internal mixer can reach 220°C, so as to meet the blending of plastics with higher melting points.

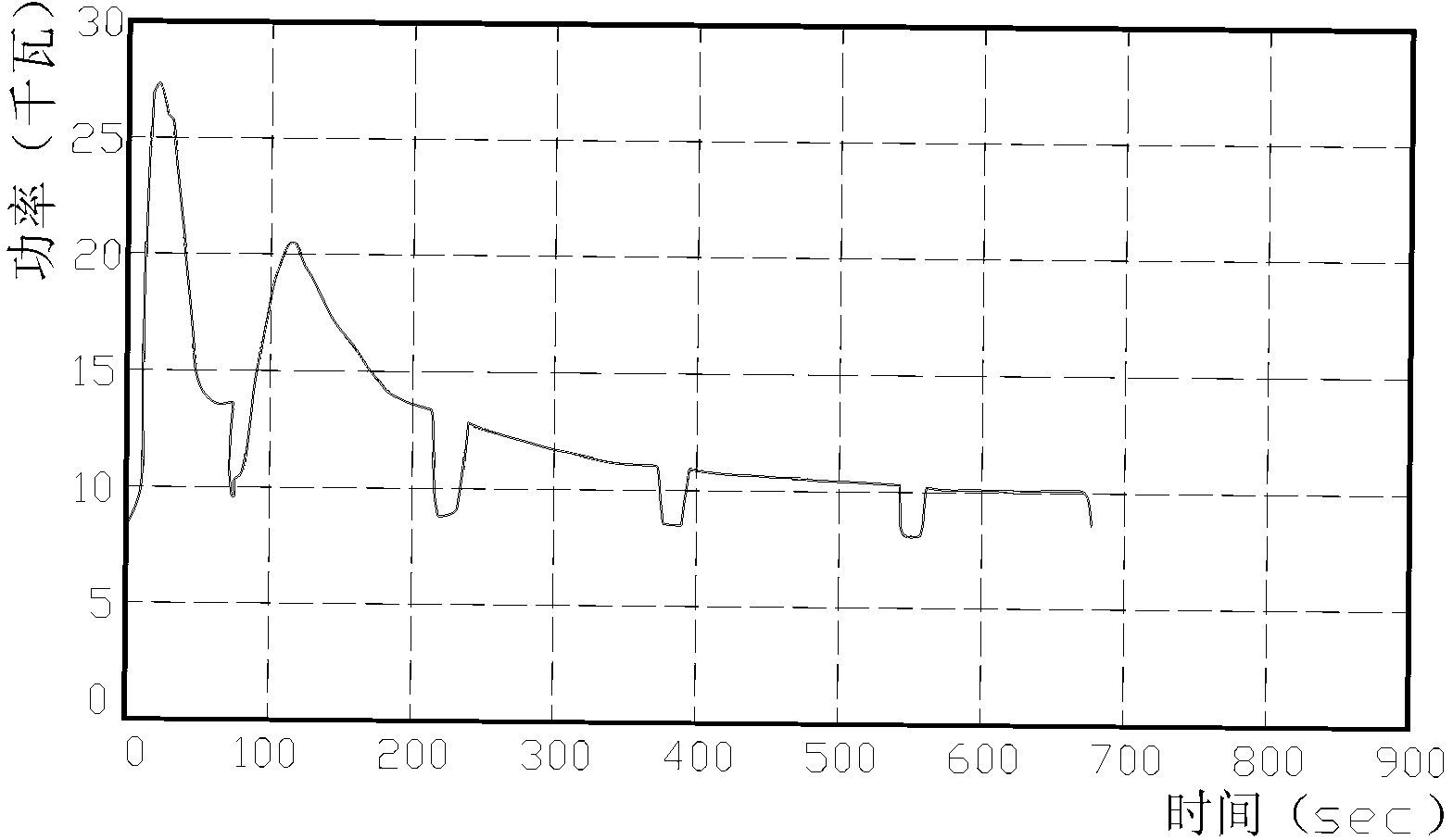

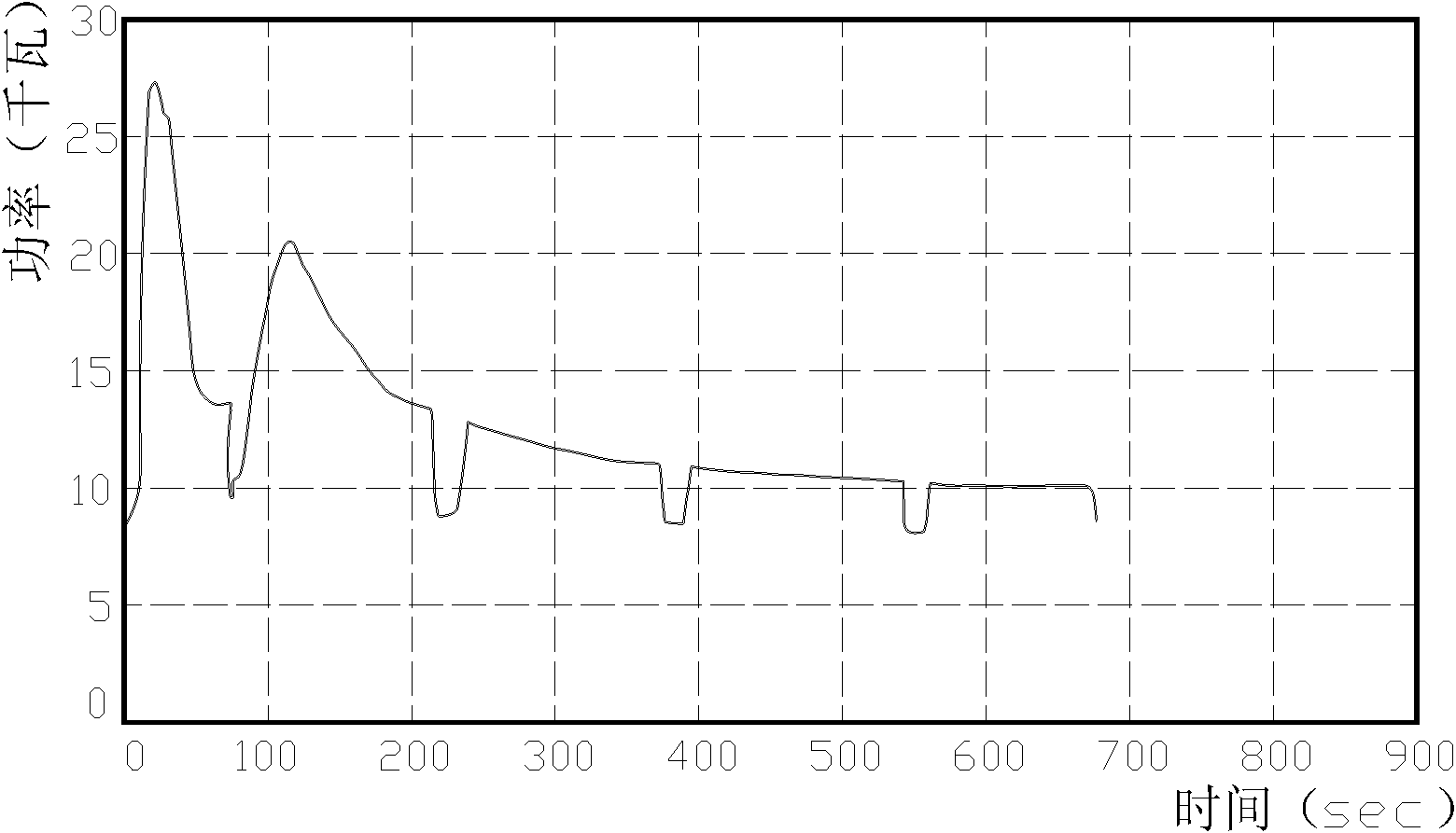

[0027] The improved plastic vulcanizate internal mixer blending process...

Embodiment 2

[0039] Utilize common rubber and plastic equipment including common internal mixer and heating and temperature control system thereof, open mill, plastic crusher and plastic extruder, prepare the EPDM rubber / polypropylene (EPDM / polypropylene) of rubber-plastic ratio 60 / 40 PP) thermoplastic vulcanizate, the equipment that present embodiment uses is with embodiment one.

[0040] The improved plastic vulcanizate internal mixer blending process includes the following steps and process conditions:

[0041] Step 1: Pre-preparation of rubber compound

[0042] Prepare materials by mass: oil-extended EPDM rubber 150 (including 50 parts of naphthenic oil), white carbon black 45, antioxidant RD 2, stearic acid 1.5, softener naphthenic oil 50, organic peroxide DCP 3 , cross-linking additive TAIC 3, polypropylene plastic 67;

[0043] Mix EPDM rubber, white carbon black, anti-aging agent, stearic acid, 30 parts of naphthenic oil, cross-linking aids and organic peroxides on the open mill a...

Embodiment 3

[0052] Using ordinary rubber and plastic equipment including ordinary internal mixer and its heating and temperature control system, open mill, plastic crusher and plastic extruder, etc., prepare high fluidity, rubber-plastic ratio 55 / 45 styrene-butadiene rubber / high-density polymer Polyethylene (SBR / HDPE) thermoplastic vulcanizate, the equipment used in this embodiment is the same as that of embodiment one.

[0053] The improved plastic vulcanizate internal mixer blending process includes the following steps and process conditions:

[0054] Step 1: Pre-preparation of rubber compound

[0055] Prepare materials by mass: oil-extended styrene-butadiene rubber 137.5 (containing 37.5 parts of oil), zinc oxide 3, stearic acid 2, antioxidant RD 2, white carbon black 45, carbon black N3308, softener naphthenic oil 50, sulfur 1.7 , Accelerator TT 1.8, HDPE 82;

[0056] Mix oil-extended styrene-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, white carbon black, N330, 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com