Preparation method of solar cell with buried charge layer

A technology of solar cells and electric charges, applied in circuits, electrical components, and final product manufacturing, etc., can solve problems such as poor resistance to high-energy particle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

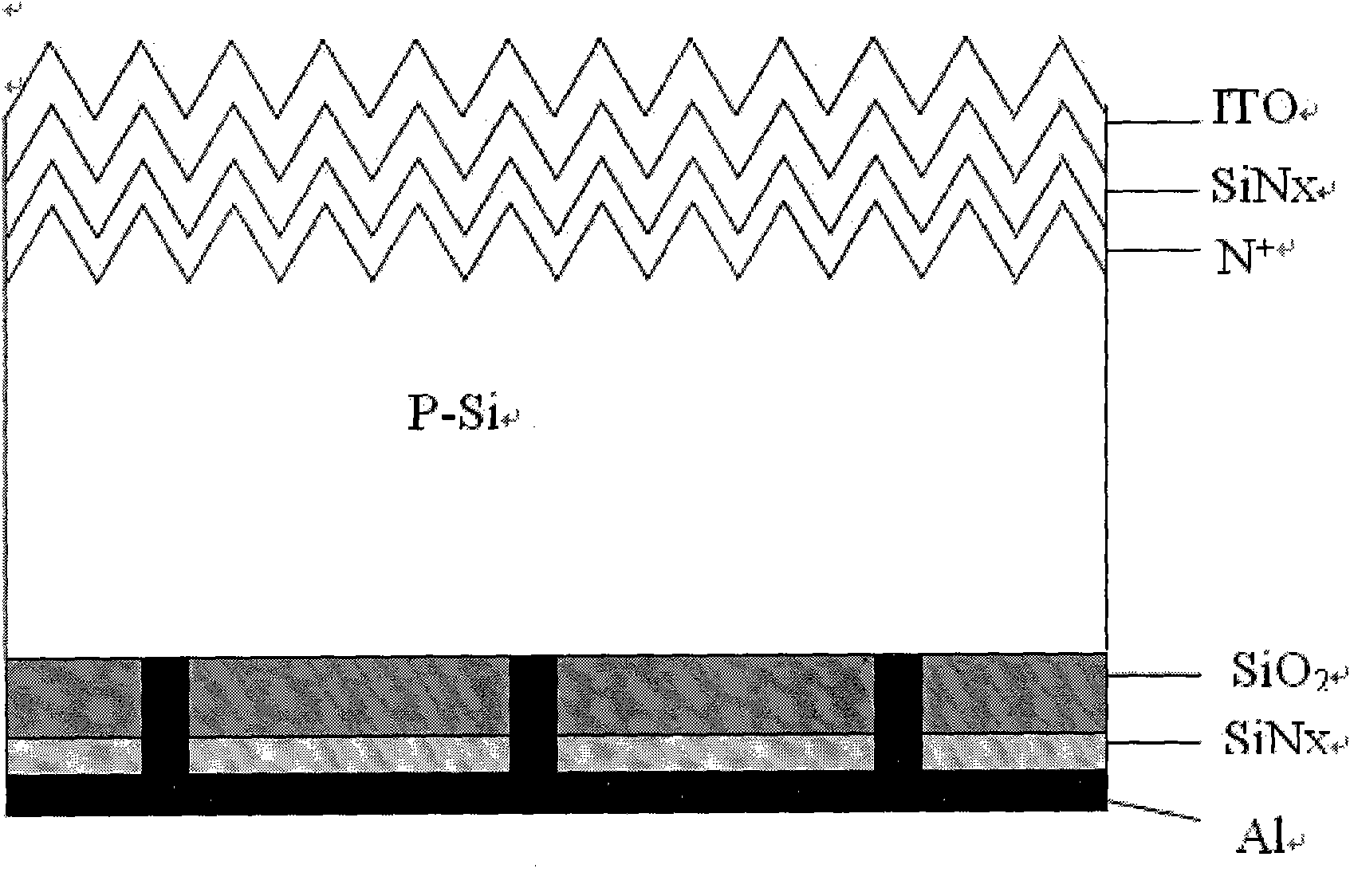

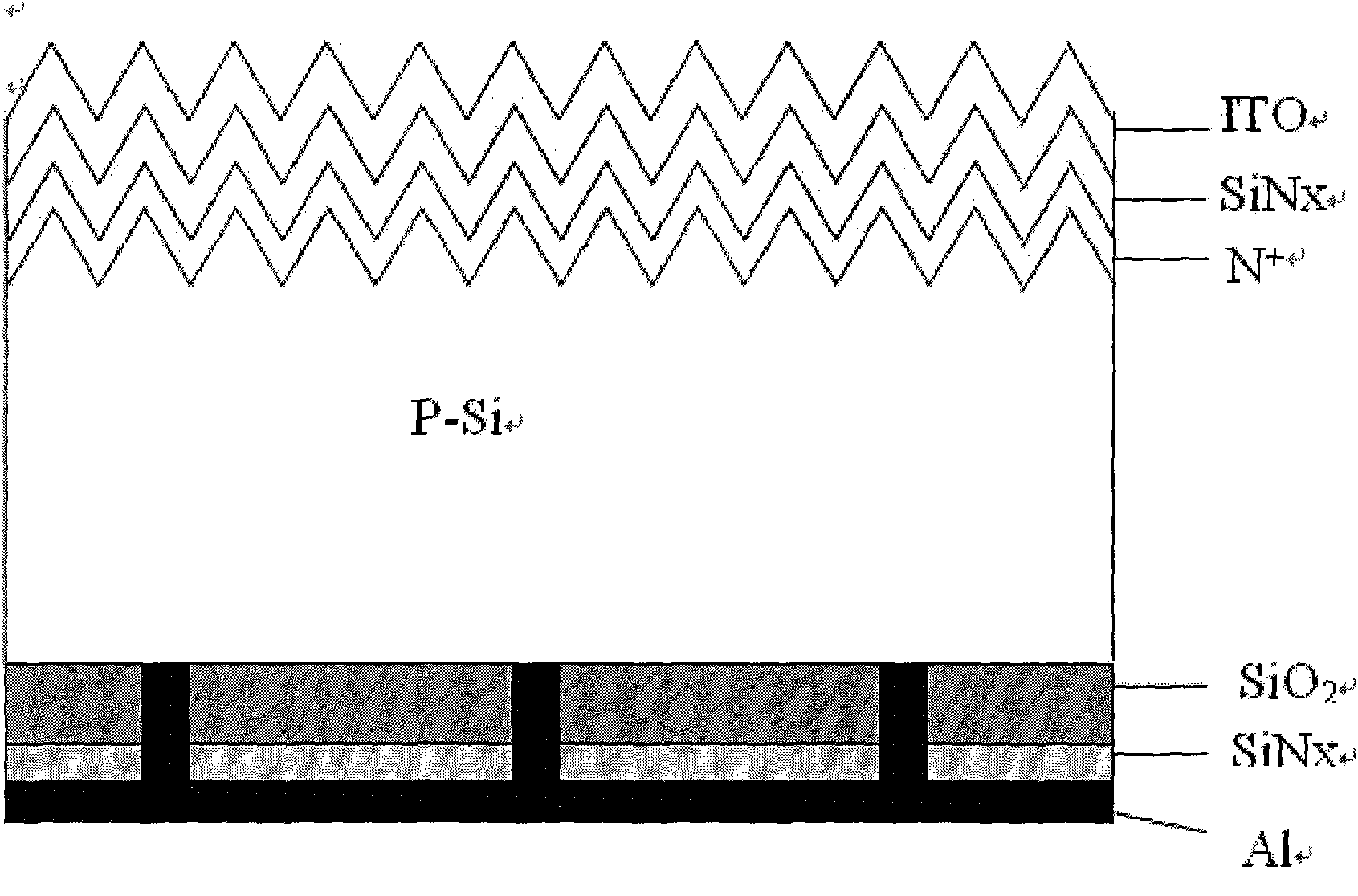

[0026] 1. The structural design of the solar cell see figure 1 .

[0027] 2. Preparation of solar cells

[0028] A (100)p-type silicon wafer is selected, with a resistivity of 3Ωcm and a thickness of 200μm.

[0029] 1. Dry oxygen:

[0030] Oxygen flow, gas flow rate 1L / min, oxidation temperature 1050°C, 20 minutes, grow a 45-50nm thick silicon oxide layer;

[0031] 2. Texturing:

[0032] Use diluted 5% HF solution to remove the oxide layer on the front surface, and use NaOH plus C 2 h 5 The OH method corrodes the texture, the temperature of the lye is about 80°C, the concentration is 1-2%, and the corrosion time is 15 minutes.

[0033] 3. Diffusion knot:

[0034] The diffusion furnace is heated up to the diffusion temperature (850-900° C.) in advance. Nitrogen gas (800ml / min) is introduced first, the silicon wafer is pushed into the constant temperature zone, and preheated for 5 minutes. Then, the nitrogen flow rate was adjusted to 60ml / min, and simultaneously the flo...

Embodiment 2

[0055] The difference between scheme two and scheme one is only in the formation process of silicon dioxide, that is, the fifth step in the specific implementation scheme. The rest of the steps are the same.

[0056] Form a silicon oxide film on the back of a silicon wafer using atomic layer deposition technology:

[0057] Use H 2 N(CH 2 ) 3 Si(OEt) 3 As a silicon source, water (H 2 O) and O 3 As an oxygen source, H 2 N(CH 2 ) 3 Si(OEt) 3 Pulse time is 1s, H 2 O pulse time is 400ms, O 3 The pulse time is 300ms, the cleaning gas is nitrogen, the pulse time is 2s, the substrate temperature is 100-200°C, the working pressure is 0.08-0.10Torr, the total pulse of precursor injection is 2400 times, and the cleaning pulse is 2400 times.

[0058] Implementation effect: Finally, the performance test of the battery is carried out, at AM1.5, 100mW / cm 2 Under the irradiation of standard light intensity, the open-circuit voltage of the 4.0cm×4.0cm monocrystalline silicon solar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com