Front electrode of solar cell

A technology of solar cells and front electrodes, which is applied in the field of solar cells, can solve the problems of being unable to adapt to the high-resistance dense grid technology, restricting the photoelectric conversion efficiency of cells, and increasing the cost of industrialization, so as to reduce the area, increase the injection, increase the open circuit voltage and Effect of short circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are only used to explain the present invention, but not to limit the present invention.

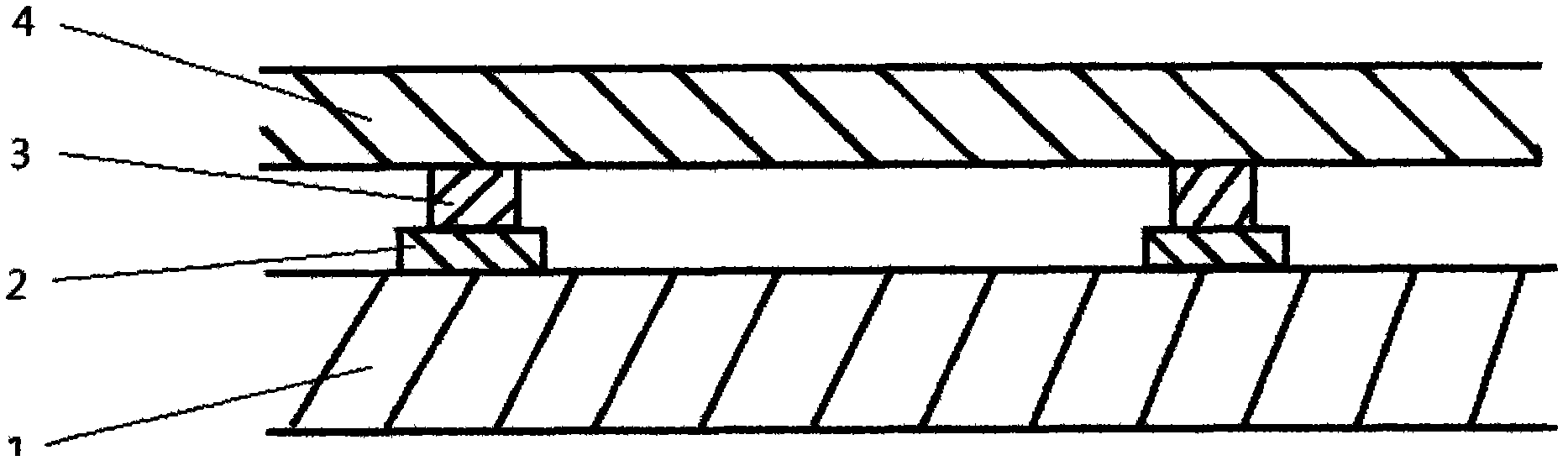

[0033] Such as figure 1 Shown is a partial schematic diagram of a solar cell bridge structure electrode structure of the present invention, a solar cell front electrode, including a semiconductor base 1, and dot-shaped electrodes 2 are regularly distributed on the semiconductor base 1, and the tops of the dot-shaped electrodes 2 are fixed with The connection part, the other end of the connection part is connected with a metal wire 4, and the metal wire 4 connects the point electrodes 2 in series along the row direction.

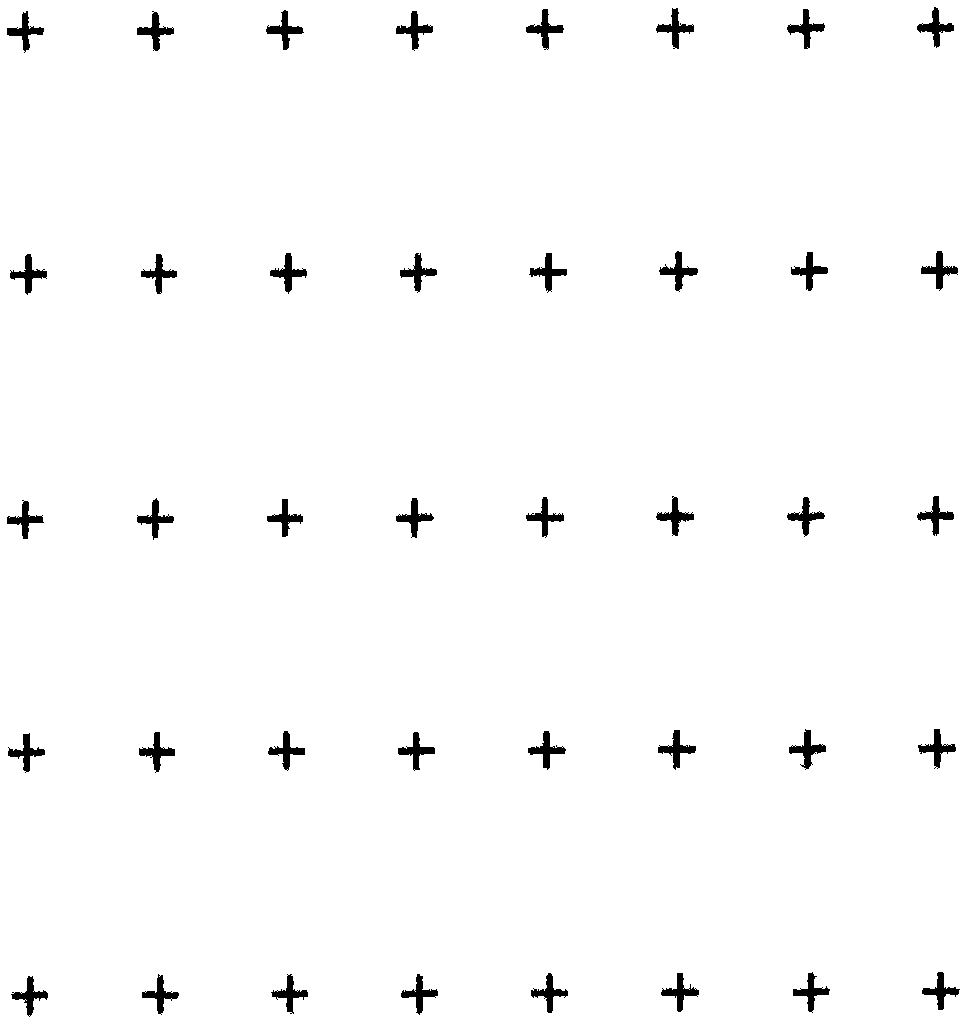

[0034] Such as figure 2 , image 3 Shown is a schematic diagram of the local area effect of a point contact electrode provided by the present invention. The poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com