Preparation method and application of metallic indium nanometer particle ink

A nano-particle and metal indium technology is applied in the field of solar energy applications, which can solve the problems of good dispersion and difficulty, and achieve the effects of dense and smooth surface, simple and easy reaction, and uniform cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

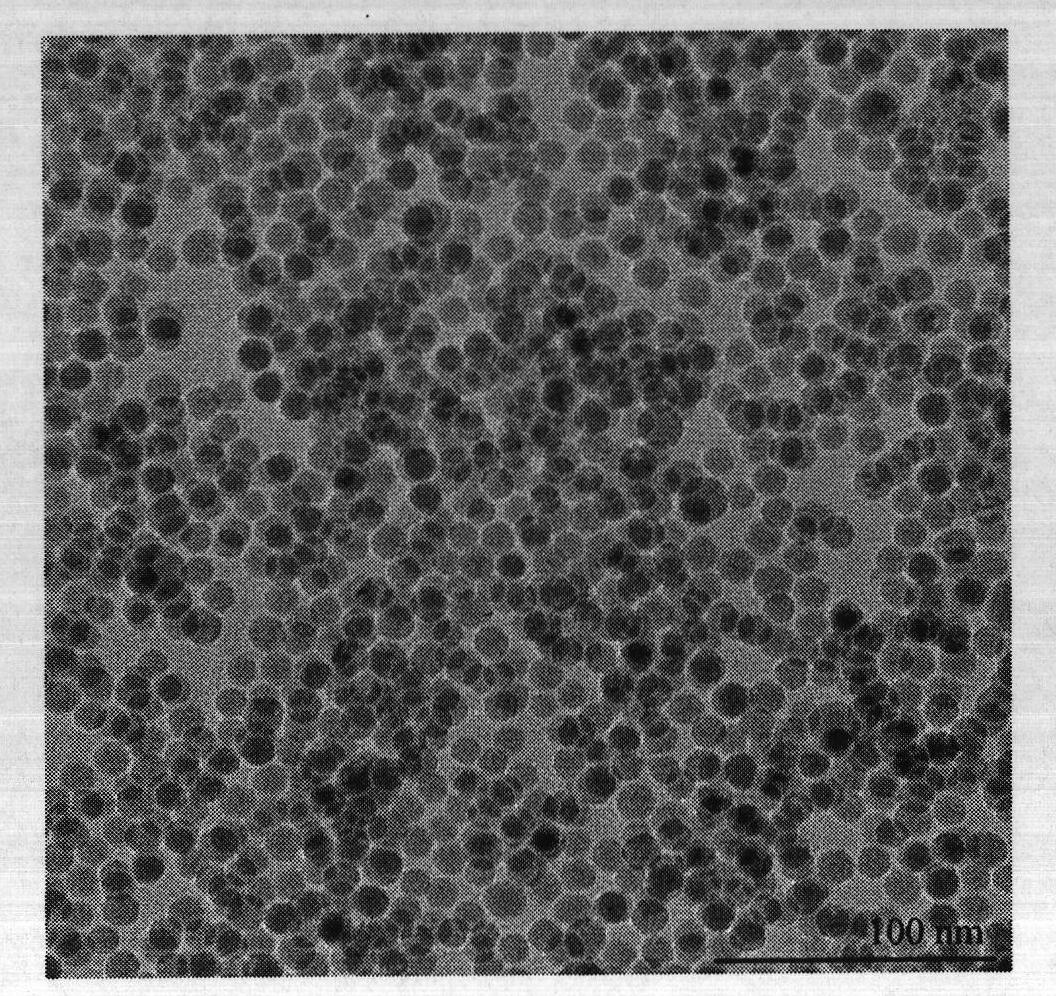

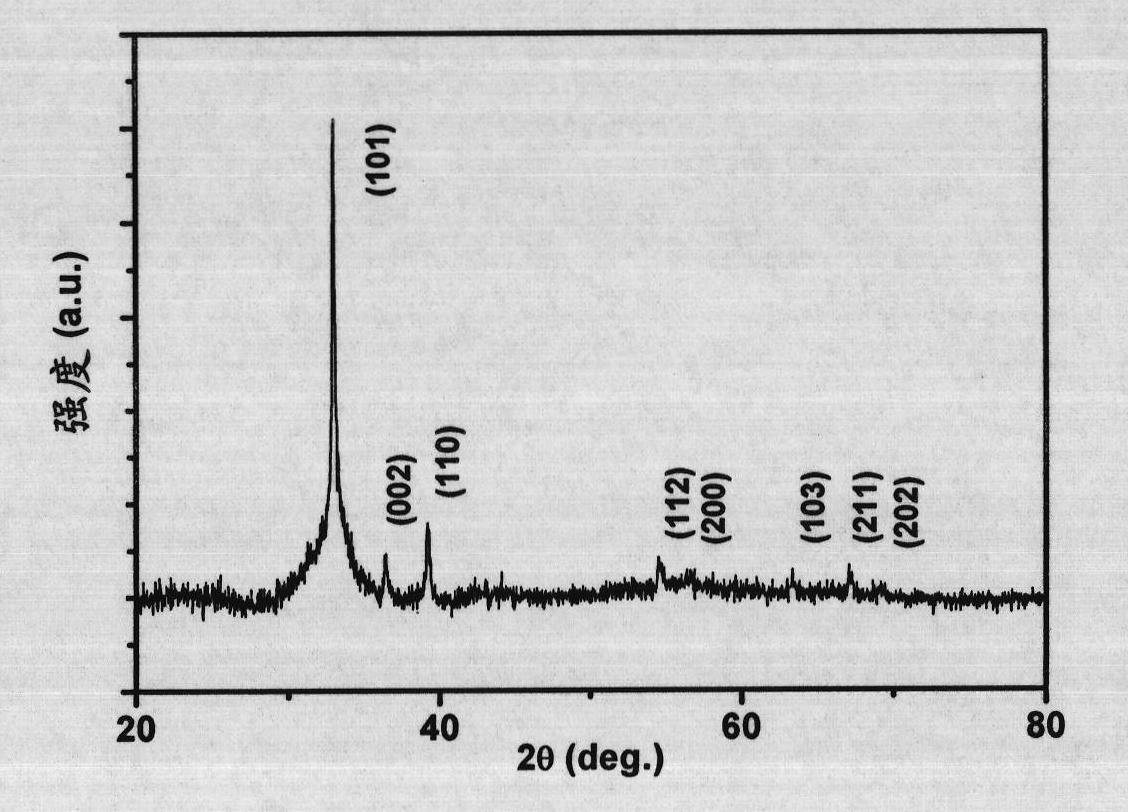

Image

Examples

Embodiment 1

[0034] 1. Configure metal indium nanoparticle ink:

[0035] (1) 1mmol InCl 3 Dissolve in 40ml of ethylene glycol at 140°C, stir magnetically for 30min under the protection of argon, and keep the temperature at 140°C. Add 1ml of triethanolamine to the solution as a stabilizer, and continue stirring for 30 minutes;

[0036] (2) Add 0.2g NaBH 4 Dissolve in 8ml tetraethylene glycol, and stir at room temperature for 15 minutes to obtain a clear solution.

[0037] (3) The alcoholic solution of sodium borohydride obtained in (2) is quickly injected into the indium chloride ethylene glycol solution obtained in (1), and the heating is stopped after reacting for 3 minutes;

[0038] (4) Centrifugally wash the product obtained in (3) with ethanol for 3 to 5 times, and dry to obtain metal indium nanoparticles;

[0039] (5) Prepare solvent according to polyvinylpyrrolidone: ethanol = 1: 300 (mass ratio); prepare ink according to the amount of metal indium nanoparticles: solvent = 1: 30 ...

Embodiment 2

[0047] 1. Configure metal indium nanoparticle ink:

[0048] (1) 1mmol InCl 3 Dissolve in 40ml of ethylene glycol at 140°C and stir magnetically for 30min under the protection of argon. Add 3ml triethanolamine in this solution as stabilizer, continue to stir for 30min;

[0049] (2) Add 0.2g NaBH 4 Dissolve in 8ml tetraethylene glycol, and stir at room temperature for 15 minutes to obtain a clear solution.

[0050] (3) quickly inject the alcoholic solution of sodium borohydride obtained in (2) into the indium glycol solution obtained in (1), and stop the reaction after reacting for 3 minutes;

[0051] (4) Centrifugally wash the product obtained in (3) with ethanol for 3 to 5 times, and dry to obtain metal indium nanoparticles;

[0052] (5) Prepare solvent according to polyvinylpyrrolidone: ethanol = 1: 300 (mass ratio); prepare ink according to the amount of metal indium nanoparticles: solvent = 1: 30 (mass ratio), and ultrasonically disperse for 30 minutes to obtain metal i...

Embodiment 3

[0059] 1. Configure metal indium nanoparticle ink:

[0060] (1) 1mmol InCl 3 Dissolve in 40ml of ethylene glycol at 80°C and stir magnetically for 30min under the protection of argon. Add 1ml of triethanolamine to the solution as a stabilizer, and continue stirring for 30 minutes;

[0061] (2) Add 0.2g NaBH 4 Dissolve in 8ml tetraethylene glycol, and stir at room temperature for 15 minutes to obtain a clear solution.

[0062] (3) quickly inject the alcoholic solution of sodium borohydride obtained in (2) into the indium glycol solution obtained in (1), and stop the reaction after reacting for 3 minutes;

[0063] (4) Centrifugally wash the product obtained in (3) with ethanol for 3 to 5 times, and dry to obtain metal indium nanoparticles;

[0064] (5) Prepare solvent according to polyvinylpyrrolidone: ethanol = 1: 300 (mass ratio); prepare ink according to the amount of metal indium nanoparticles: solvent = 1: 30 (mass ratio), and ultrasonically disperse for 30 minutes to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com