Production method and production device of tantalum powder

A production device and technology of tantalum powder, which is applied in the field of alkali metal reduction potassium fluorotantalate to produce tantalum powder and sodium reduction reaction device, can solve environmental pollution and other problems, and achieve the effect of reducing production cost and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

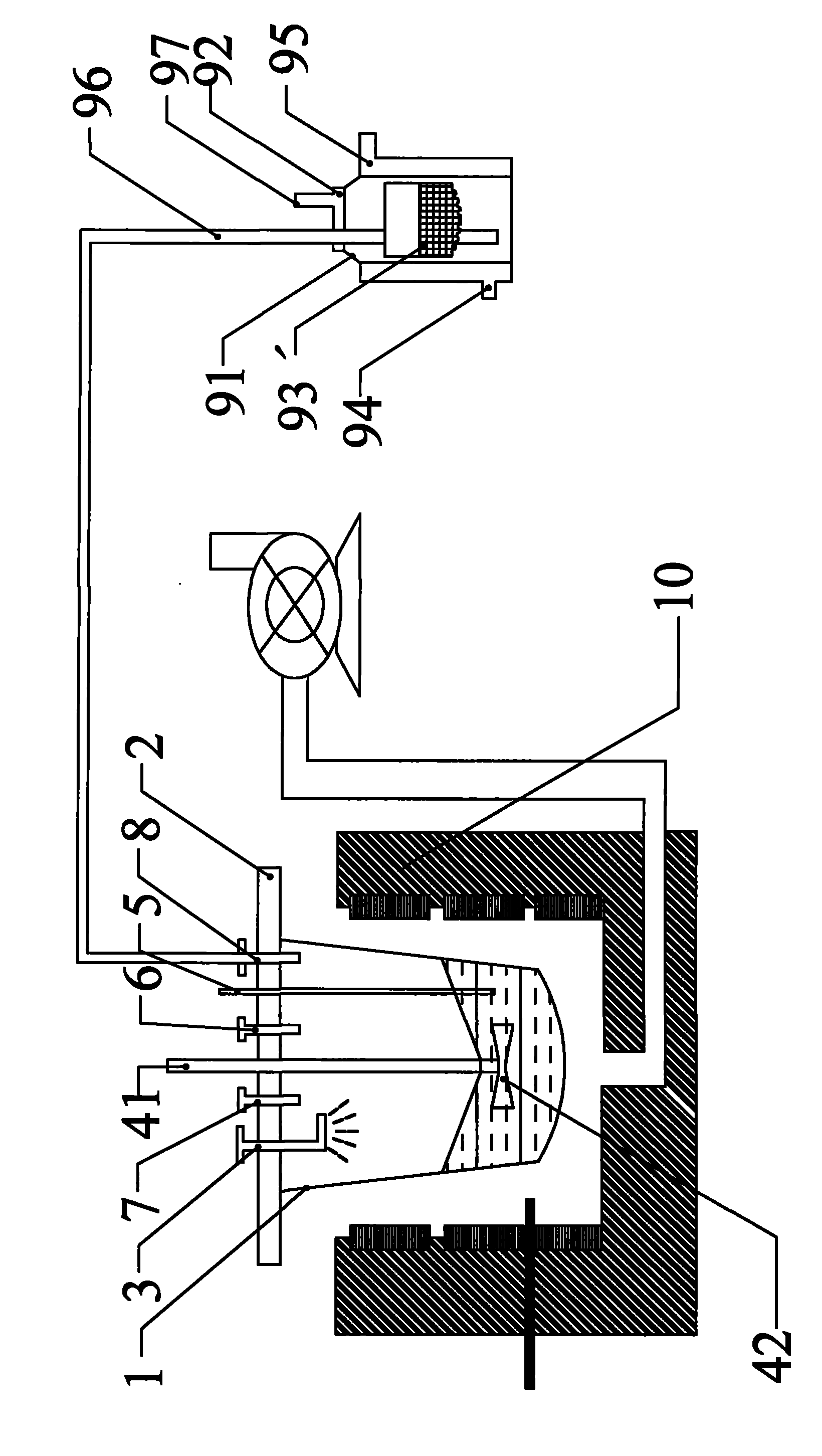

[0034] Use as figure 1 In the device shown, the intake pipe 96 of the alkali metal collector is connected to the exhaust port 8 of the reaction vessel 1. Load 160kg of potassium fluorotantalate and 100kg of sodium chloride into reaction vessel 1, evacuate and fill with argon gas, hoist the reaction vessel into electric heating furnace 10, raise the temperature to 900°C, stir, and keep it warm for 1 hour before starting injection Sodium, 49kg of metallic sodium was injected. Continue to stir and keep warm, feed argon from the gas filling port 7 and exhaust from the exhaust port 8 for 20 minutes. Then stop heating and continue to inflate and exhaust. When the temperature in the reaction vessel drops to 800°C, connect the exhaust port of the alkali metal collector to a vacuum pump for evacuation, evacuate for 1 hour, and then cool to room temperature. The solidified product in the reaction vessel was taken out, crushed and washed with water to obtain 70.13 kg of tantalum powder, ...

Embodiment 2

[0038] Use as figure 2 In the device shown, the intake pipe 96 of the alkali metal collector is connected to the exhaust port 8 of the reaction vessel 1. Put 100kg of potassium chloride, 60kg of sodium chloride and 40kg of potassium fluoride into reaction vessel 1, evacuate and fill with argon gas, hoist the reaction vessel into electric furnace 10, heat up to 850°C, stir, and keep it warm for 1 hour. Add 30kg potassium fluorotantalate into reaction vessel 1, start to inject sodium and continue stirring, then divide into 3 times, add 20kg potassium fluorotantalate each time, and start sodium injection after adding potassium fluorotantalate. A total of 90 kg potassium fluorotantalate was added, and 27.6 kg metal sodium was injected. Continue to stir and keep warm, feed argon from the gas filling port 7 and exhaust from the exhaust port 8 for 20 minutes. Then stop heating and continue to inflate and exhaust. When the temperature in the reaction vessel drops to 600°C, connect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com