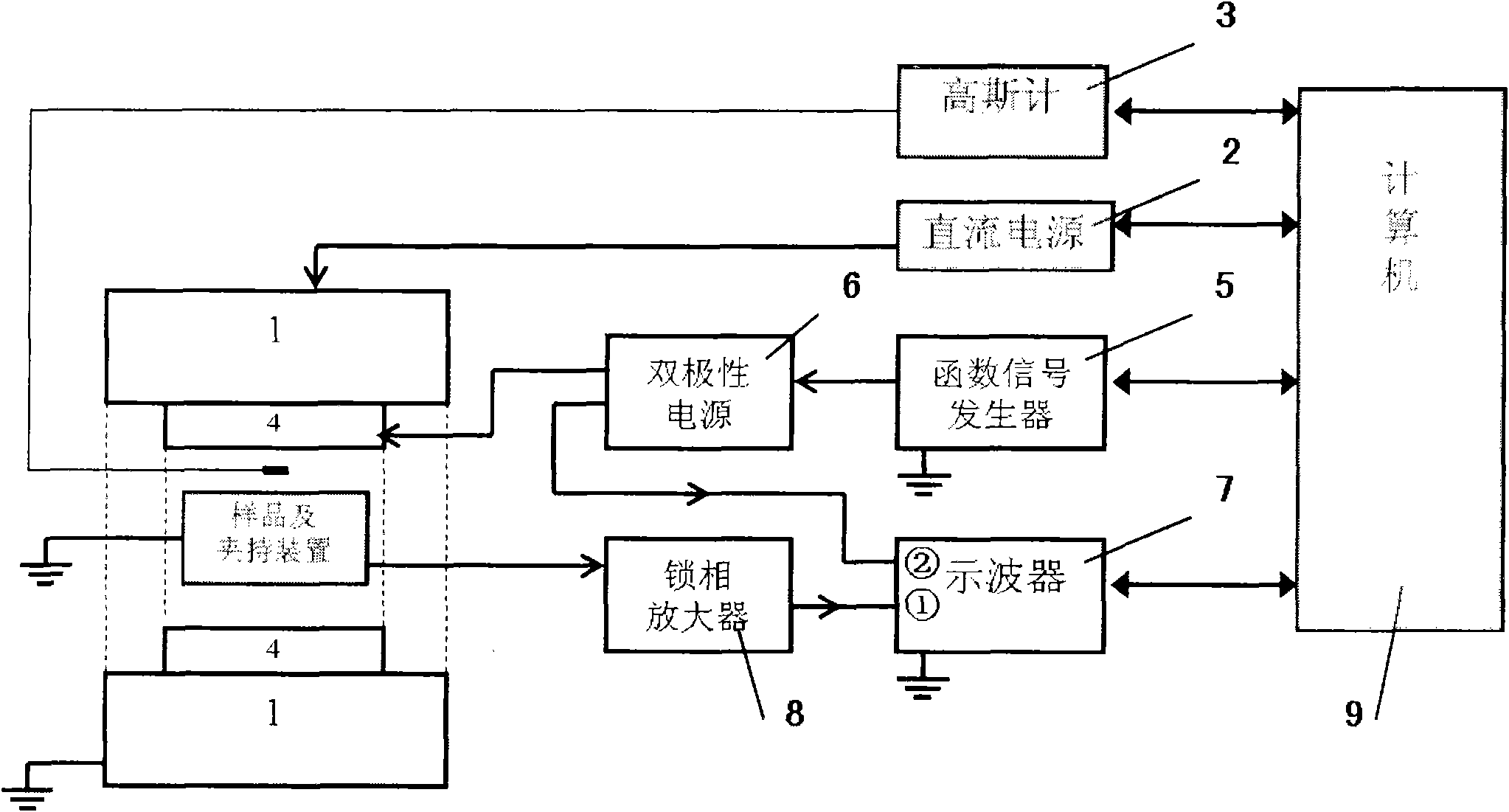

System and method for testing magnetoelectricity property of multiferroic thin-film material

A thin-film material and testing system technology, applied in the direction of magnetic performance measurement, etc., can solve the problem of unavoidable, inability to accurately measure the response signal, weak signal, etc., and achieve the effect of eliminating the influence of induced electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

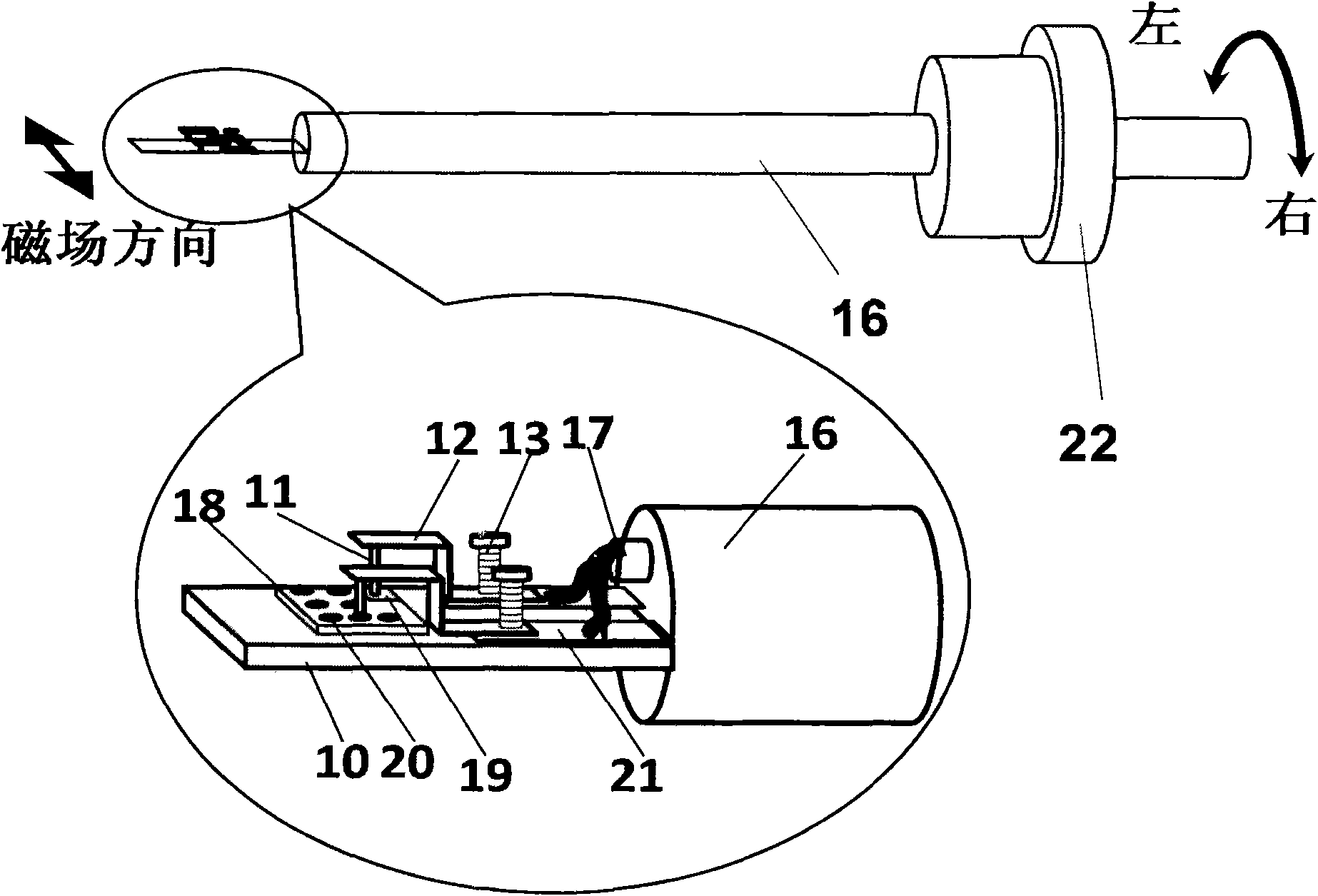

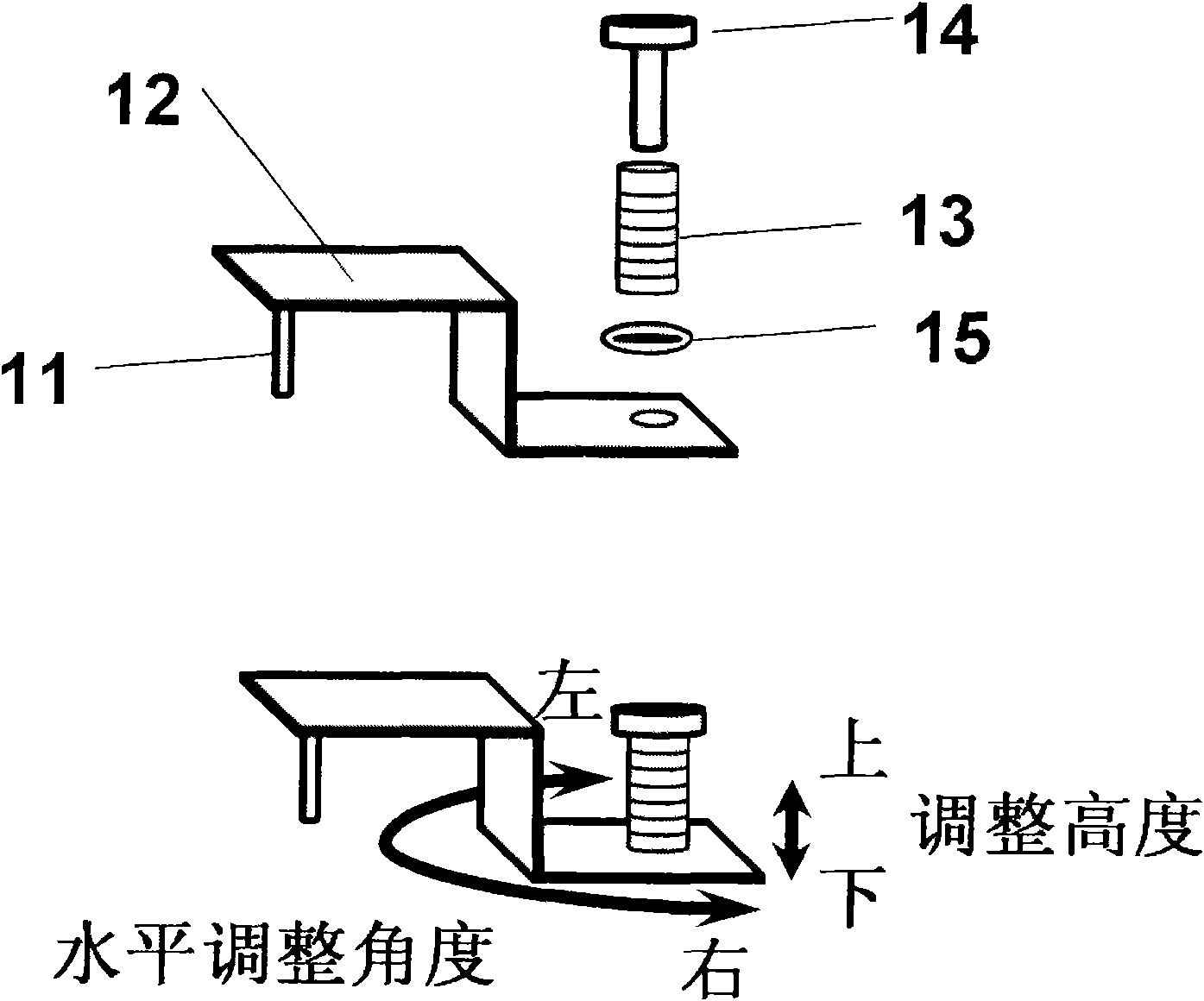

[0087] a) Example 1: Lead zirconate titanate (PZT)-cobalt ferrite (CFO) laminated multiferroic composite film

[0088] The lead zirconate titanate (PZT)-cobalt ferrite (CFO) laminated multiferroic composite film was prepared on the platinum-coated silicon substrate by the sol-gel method, and the electrode on the surface of the platinum-coated film was prepared. Hold it on the sample stage and fix it on the sample rod to ensure good contact, set H DC , f, make the alternating magnetic field generate a square wave waveform, then turn the turntable to gently rotate the sample rod within the range of ±5°, wait for the peak part in the response signal waveform to be eliminated, fix the angle, and change the DC bias magnetic field value in turn, through The computer reads the magnitude of the magnetoelectric signal under each bias magnetic field sequentially from the lock-in amplifier, and obtains the change law between the amplitude of the magnetoelectric coefficient and the DC bia...

example 2

[0089] b) Example 2: Barium titanate (BTO)-nickel ferrite (NFO) laminated multiferroic composite film

[0090] The barium titanate (BTO)-nickel ferrite (NFO) laminated multiferroic composite film was prepared on the niobium-doped strontium titanate single crystal substrate by pulsed laser deposition, and the electrode on the upper surface of the film was plated with platinum, and the sample to be tested was Clamp the probe on the sample stage and fix it on the sample rod to ensure good contact, set H DC 、H DC , so that the alternating magnetic field produces a sinusoidal waveform, and then turn the turntable to gently rotate the sample rod within the range of ±5°. When the phase difference between the response signal waveform and the reference signal is 0 or π, fix the angle, and change the frequency of the driving magnetic field in turn, through The computer reads the magnitude of the magnetoelectric signal under each bias magnetic field sequentially from the lock-in amplifi...

example 3

[0091] c) Example 3: Bismuth ferrite (BFO) single-phase multiferroic thin film

[0092] Using the sol-gel comparison method to prepare a bismuth ferrite single-phase multiferroic film on a platinum-plated silicon substrate, and plate an electrode on the surface of the platinum film, clamp the sample to be tested on the sample stage with a probe and fix it on the sample rod to ensure Good contact, set f, H DC =0Oe, make the alternating magnetic field generate a sine wave, then turn the turntable to rotate the sample rod slightly within the range of ±5°, when the phase difference between the response signal waveform and the reference signal is 0 or π, fix the angle, and change the driving magnetic field in turn Amplitude, the magnitude of the magnetoelectric signal under the alternating magnetic field of each different size is sequentially read from the lock-in amplifier by the computer, and the relationship between the electric polarization and the frequency of the alternating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com