Polycrystalline silicon texturing method

A technology of polycrystalline silicon wafer and acid texturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

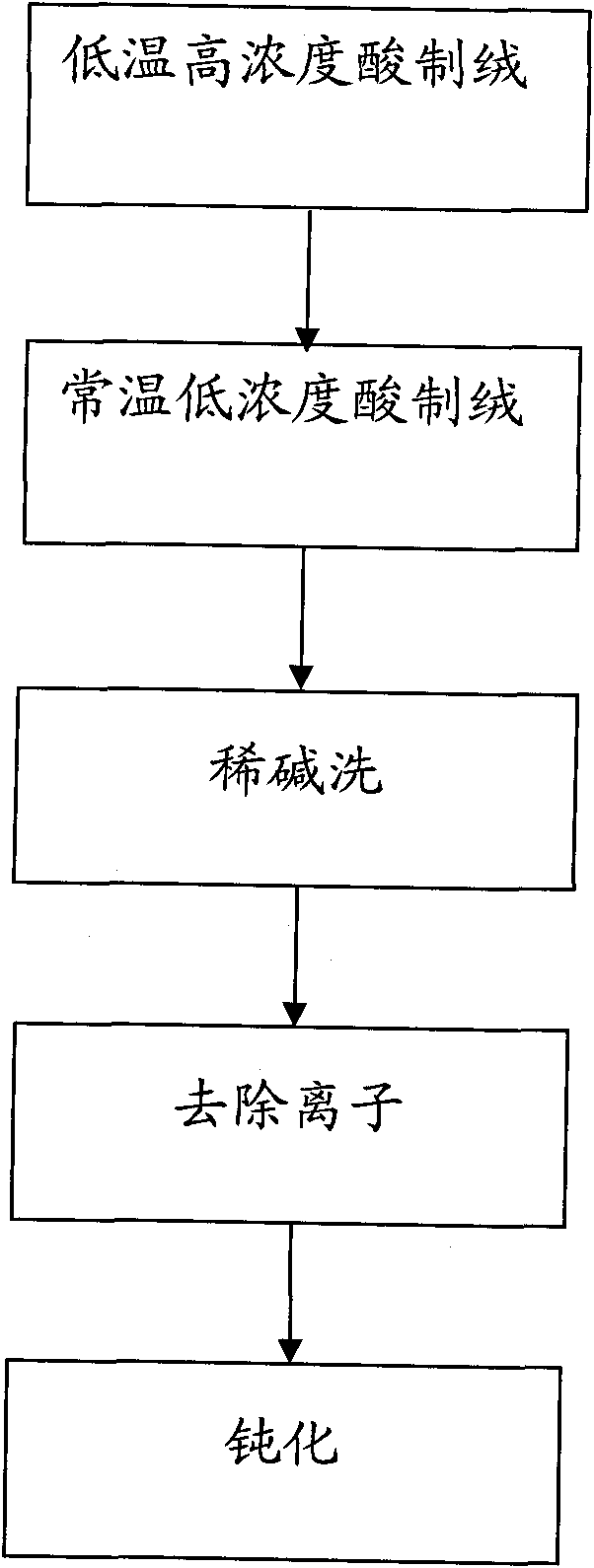

[0025]A polycrystalline silicon wafer texturing method, comprising the following steps: low-temperature high-concentration acid texturing, normal-temperature low-concentration acid texturing, dilute alkali washing, ion removal and passivation, the low-temperature high-concentration acid texturing and normal temperature low The acid treatment solution used in the high-concentration acid texture is a mixed acid solution of nitric acid, hydrofluoric acid and pure water.

[0026] The first step is low-temperature high-concentration acid velvet. The acid treatment solution used is a mixed acid solution of nitric acid with a mass fraction of 55%-65%, hydrofluoric acid with a mass fraction of 40%-55%, and pure water. Among them, nitric acid (HNO 3 ) volume fraction of 40%-60%, hydrofluoric acid (HF) volume fraction of 10%-25%, pure water (H 2 The volume fraction of O) is 15%-50%. Under the condition of 0.1MPa air pressure and circulating cooling, the liquid temperature is controlled...

Embodiment 1

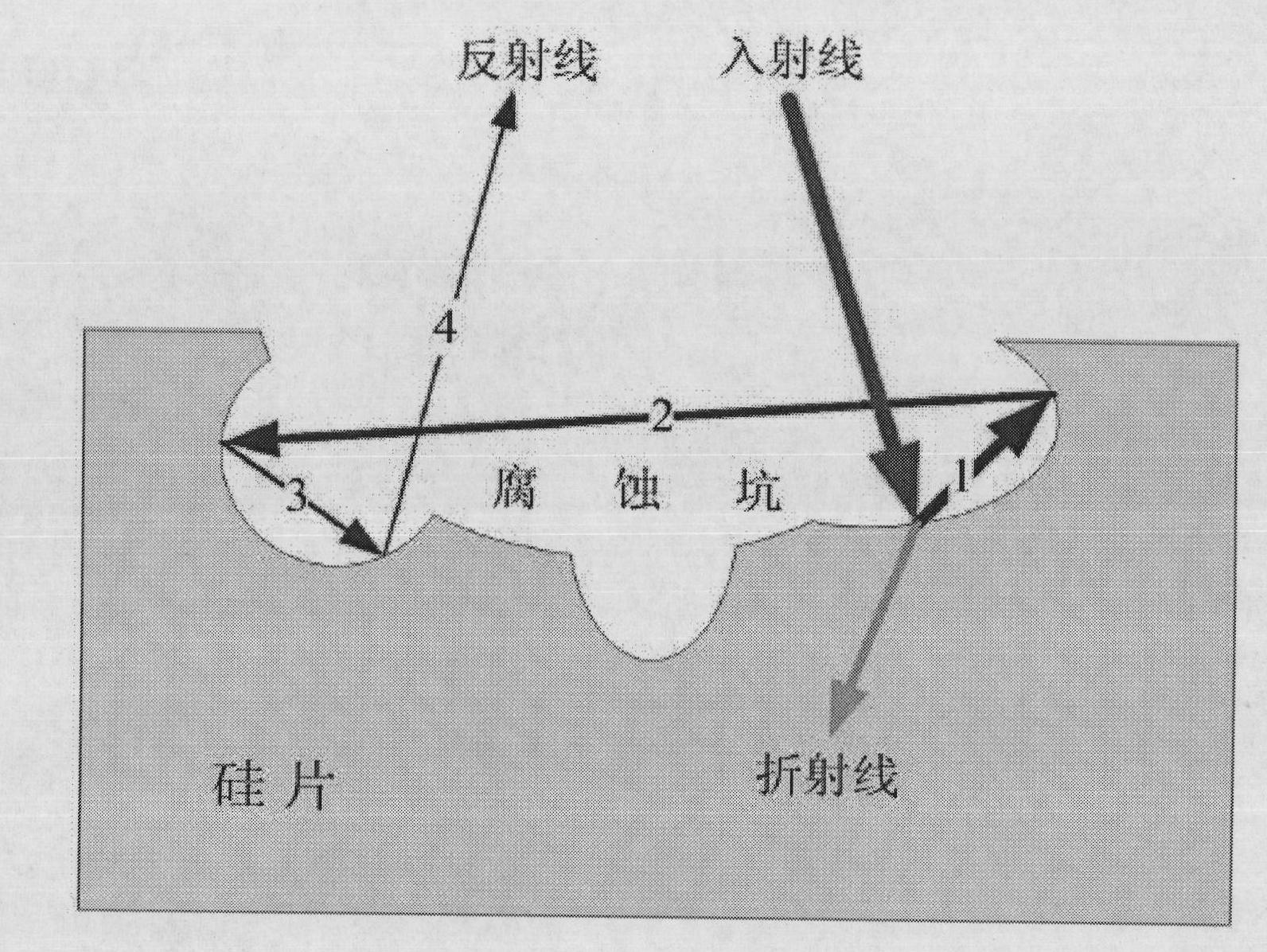

[0030] In the low-temperature high-concentration acid texturing process, the nitric acid (HNO 3 ) and hydrofluoric acid (HF) and pure water (H 2 The volume fractions of O) are 46.5%, 18.6%, and 34.9%, respectively. The polycrystalline silicon chip is immersed in the above-mentioned mixed acid solution at a temperature of 15°C. 3 The nitrogen gas per hour is disturbed, and the etching process is carried out for 80 seconds, and a slightly wider shallow etching pit (about 5um in width) is formed on the surface of the silicon wafer, (see Figure 4 ), the grain boundary corrosion is shallow, there is no obvious color difference between grains, no flower basket printing, and the available reflectance is 28.01% (see Figure 6 As shown in the middle curve 2), the surface damage layer can be effectively removed, the surface recombination of the battery can be reduced, and the surface light absorption is less.

[0031] In the normal temperature low-concentration acid texturing process,...

Embodiment 2

[0033] The first step is low-temperature and high-concentration acid velvet making. Nitric acid (HNO 3 ), hydrofluoric acid (HF) and pure water (H 2 The volume fraction of O) is 56.9%, 20.3%, and 22.8% respectively. The polysilicon wafer is immersed in the above-mentioned acidic treatment solution with a temperature of 8°C. 3 Under the condition of nitrogen perturbation per hour and the cooling device turned on for 50 seconds, the corrosion pits on the surface of the silicon wafer are shallow, the grain boundary corrosion is shallow, there is no obvious color difference between the grains, no flower basket printing, and the surface damage layer is effectively removed. Reduce battery surface recombination.

[0034] The second step is to make texture with low-concentration acid at room temperature. Wash the silicon wafers treated in the first step and immerse them in the acidic treatment solution for texturing, in which nitric acid (HNO 3 ), hydrofluoric acid (HF) and pure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com