Preparation method of Fe3O4 nano-magnetic powder lymphatic tracer and application thereof

A nano-magnetic powder and magnetic separation technology, applied in the preparations, pharmaceutical formulations, ferrous oxides, etc. for in vivo experiments, can solve the difficulty of lymphatic system targeting, low lymphatic uptake rate, and biocompatibility. Not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

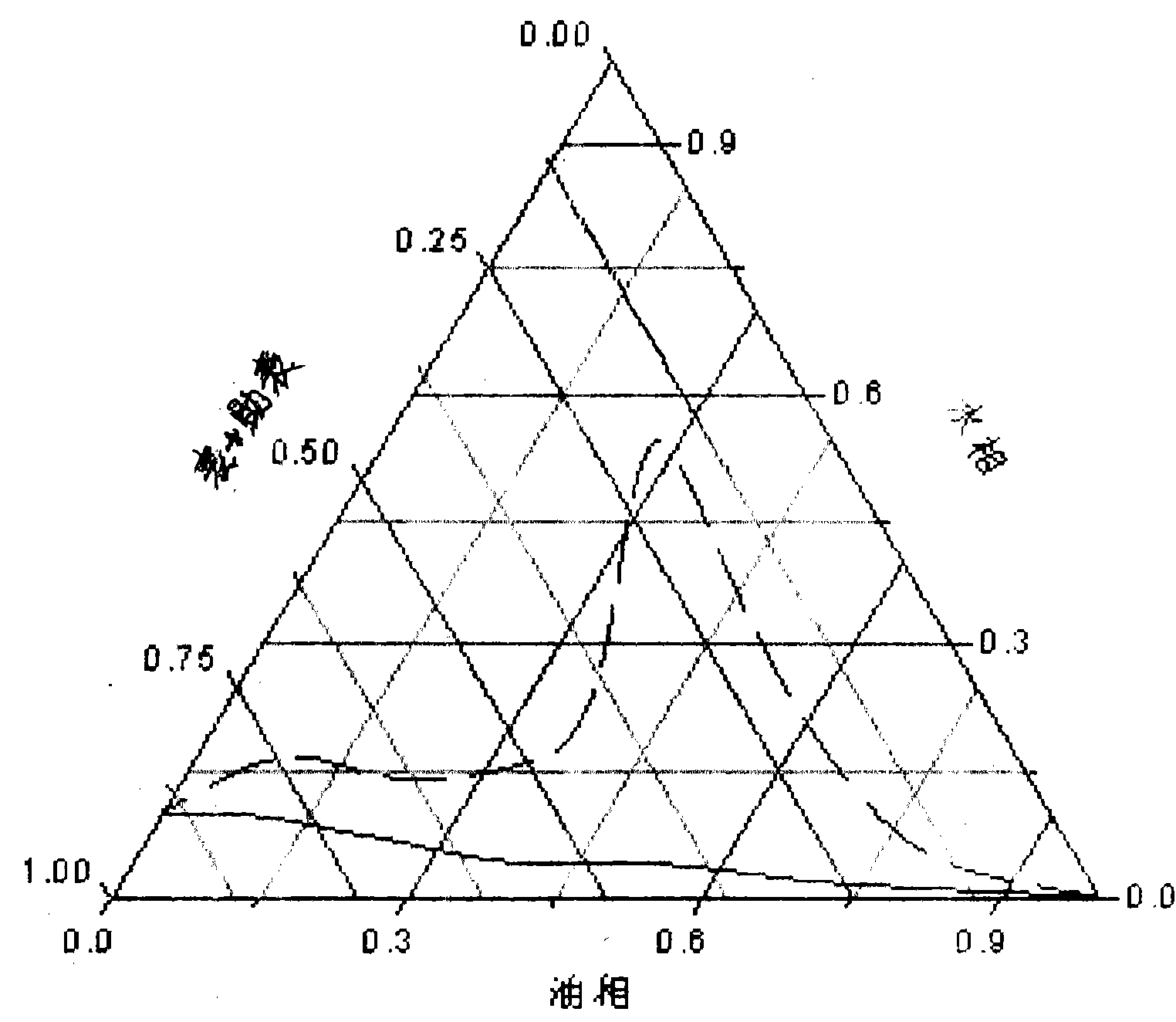

Embodiment 1

[0026] Prepare c(Fe 3+ )=0.18mol / L, c(Fe 2+ )=0.12mol / L, after mixing as the water phase, 73.02g of cetyltrimethylammonium bromide (CTAB), 49.57g of n-butanol, and 347.01g of cyclohexane are mixed as the oil phase, and titrated with the water phase Oil phase, ultrasonic dispersion, to get W / O microemulsion. A certain amount of excess triethanolamine was added dropwise at a slow speed to control the pH value of the microemulsion. After the reaction is complete, the emulsion is broken, and the precipitate is separated with an ultra-high speed centrifuge. The obtained precipitate was washed with ethanol and distilled water three times respectively. Evaporate naturally to get nano-Fe 3 o 4 powder. The particle size of the product is 200nm.

Embodiment 2

[0028] Prepare c(Fe 3+ )=0.18mol / L, c(Fe 2+ )=0.12mol / L, after mixing as the water phase, 72.92g of cetyltrimethylammonium bromide (CTAB), 49.24g of n-butanol, and 346.01g of cyclohexane are mixed as the oil phase, and titrated with the water phase Oil phase, ultrasonic dispersion, to get W / O microemulsion. A certain amount of excess triethanolamine was added dropwise at a slow speed to control the pH value of the microemulsion. After the reaction is complete, the emulsion is broken, and the precipitate is separated with an ultra-high speed centrifuge. The obtained precipitate was successively washed three times with distilled water, hydrochloric acid and PEG mixture. Evaporate naturally to get nano-Fe 3 o 4 powder. The particle size of the product is 90nm.

Embodiment 3

[0030] 3.1 Prescription drugs

[0031] Pharmaceutical nano-Fe 3 o 4 powder 30g

[0032] Polyvinylpyrrolidone K-30 (PVP) 12g

[0033]Normal saline (0.9%) 1000ml

[0034]

[0035] Get 1000 bottles of nano-suspension injection preparation

[0036] 3.2 Preparation process

[0037] Weigh a certain amount of Fe 3 o 4 Nano-magnetic powder is dispersed in normal saline for 10mm by ultrasonic wave, then diluted with normal saline, and the pH value is adjusted to 6.9 with 10% sodium hydroxide solution with a mass fraction of 10%, and finally a medicinal Fe with a concentration of 30mg / mL is formulated with PVP as a dispersant. 3 o 4 Nanosuspension injection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com