Metal oxide thin film transistor and preparation method thereof

A technology for oxide thin films and transistors, which is used in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc. to improve interface contact, increase process difficulty, and reduce off-state current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

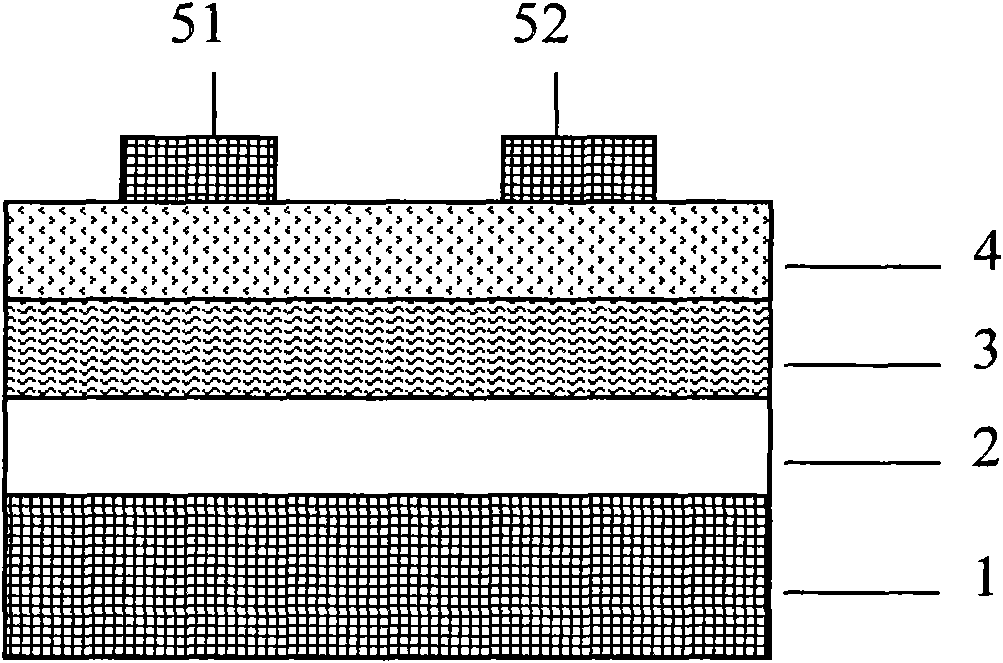

[0030] Use a highly doped silicon wafer as the gate 1, thermally oxidize a layer of silicon dioxide with a thickness of 300nm on it as the insulating layer 2, and measure its permittivity C i 11.4nF / cm 2 .

[0031] The transition layer 3 is prepared on the insulating layer 2 by radio frequency (RF) sputtering, and the target used for sputtering is indium gallium zinc oxide (InGaZnO), where In 2 o 3 , Ga 2 o 3 The molar ratio of ZnO and ZnO is 1:1:2; the theoretical value content of oxygen calculated by the molar ratio is (x=1, y=1, z=2): [(3x+3y+z) / (5x+ 5y+2z)]=[(3+3+2) / (5+5+4)]=57.1%; Oxygen (O 2 ) flow is 25SCCM, the flow of argon (Ar) is 10SCCM, O 2 / Ar=2.5; the sputtering power is 100W, and a high oxygen content indium gallium zinc oxide (InGaZnO) film with a thickness of 5nm is obtained.

[0032] The semiconductor layer 4 is prepared on the transition layer 3 by radio frequency (RF) sputtering. The target material used for sputtering is also indium gallium zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com