Method for improving SAM synthetase expression level

A technology for expression and synthesis of enzymes, which is applied in the field of biopharmaceuticals, can solve the problems of low enzyme activity, low content, and difficulty in separation and purification, and achieve the effect of increasing expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

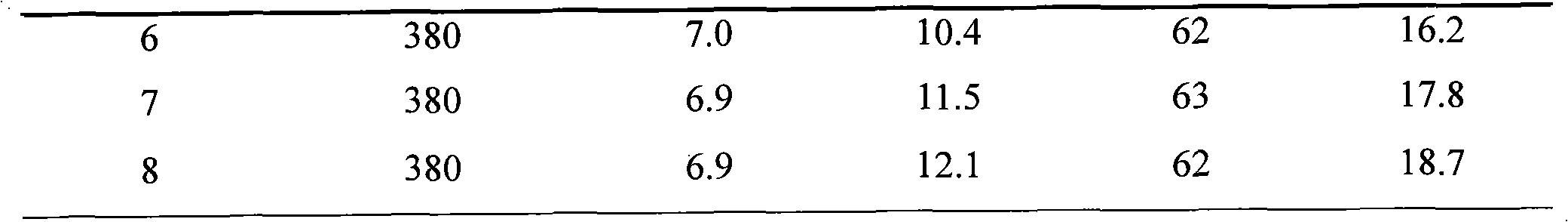

[0042] Embodiment 1 Fermentation experiments without adding divalent metal ions and flocculants

[0043] 1. Preparation of fermentation broth:

[0044] Prepare seed medium, fermentation medium and feed medium respectively according to the following formulas:

[0045] (1) Seed medium (LB medium): peptone: yeast powder: sodium chloride = 2:1:2

[0046] (2) Fermentation basal medium (g / 100ml medium):

[0047] Glucose: 1.47 Peptone: 0.4

[0048] Yeast powder: 0.55 Potassium dihydrogen phosphate: 0.4

[0049] Dipotassium hydrogen phosphate: 0.65 Ammonium sulfate: 0.047

[0050] Ammonium chloride: 0.01 Ferrous sulfate: 0.002

[0051] Manganese sulfate: 0.0007

[0052] 200mg / ml Oxytetracycline: 0.0125 (V / V)

[0053] (3) Feed medium (g / 100ml medium):

[0054] Glucose: 1.12 Yeast powder: 0.55

[0055] Magnesium sulfate: 0.035

[0056] 2. Fermentation process:

[0057] (1) Insert the glycerol species containing the recombinant bacteria into the primary seed medium (LB medium)...

Embodiment 2

[0066] (7) Stop the fermentation after 8.5 hours, take a sample and measure the expression level of SAM synthetase in it by SDS-PAGE polyacrylamide electrophoresis, and determine that the expression level of the target enzyme accounts for 30.8% of the soluble protein of the bacteria. Embodiment 2 adds Mg 2+ Fermentation experiment with flocculant

[0067] 1. Preparation of fermentation broth:

[0068] Prepare seed medium, fermentation medium and feed medium respectively according to the following formulas:

[0069] (1) Seed medium (LB medium) (%): peptone: yeast powder: sodium chloride = 2:1:2

[0070] (2) Fermentation basal medium (g / 100ml medium):

[0071] Glucose: 1.47 Peptone: 0.4

[0072] Yeast powder: 0.55 Potassium dihydrogen phosphate: 0.4

[0073] Dipotassium hydrogen phosphate: 0.3 Disodium hydrogen phosphate: 0.35

[0074] Ammonium sulfate: 0.047 Magnesium sulfate: 0.05

[0075] Ammonium chloride: 0.01 Ferrous sulfate: 0.002

[0076] Calcium chloride: 0.002 ...

Embodiment 3

[0090] Embodiment 3 adds Zn 2+ Fermentation experiment with flocculant

[0091] Repeat the steps of Example 2, the difference is that in the fermentation basal medium, the added Zn 2+ The amount of flocculant added is 0.15g / 100ml medium, the amount of flocculant disodium hydrogen phosphate added is 0.2g / 100ml medium, the amount of flocculant calcium chloride added is 0.001g / 100ml medium, other conditions are the same .

[0092] Stop fermentation after 8.5 hours, stop fermentation after 8.5 hours, take a sample and measure the expression level of SAM synthetase wherein with SDS-PAGE polyacrylamide electrophoresis, measure the expression level of target enzyme to account for 36.7% of thalline soluble protein, relative embodiment 1 ( Without adding this divalent metal ion), the expression level of SAM synthetase increased by 5.9%; the turbidity after 8 hours was 12.2, which decreased by 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com