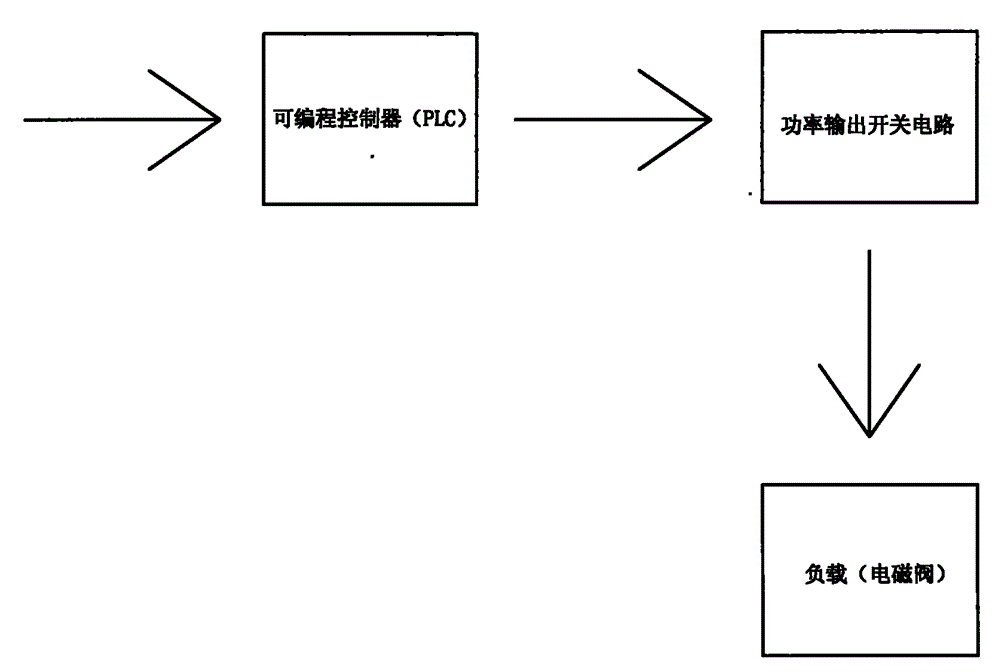

Power output switching circuit

A switching circuit and power output technology, which is applied in the field of switch modules of refill assembly machines, can solve the problems of reducing downtime, reducing maintenance costs, and short service life, and achieves the effect of reducing downtime, reducing maintenance costs, and solving short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: a kind of power output switch circuit, comprises programmable logic controller (PLC) output interface connector JP0, load terminal connector JP1 and several groups of switching loops 1, two of described PLC output interface connector JP0 use The energy terminal is connected in parallel to form the chip working voltage (VDD) receiving terminal, the two enabling terminals of the load terminal connector JP1 are connected in parallel to form the chip working voltage (VDD) transmitting terminal, the anode of the diode D01 is connected in series to the VDD transmitting terminal, and the negative pole of the diode D01 The VDD receiving end is connected in series, and the VDD sending end, the diode D01 and the VDD receiving end correspondingly connected in series form a power supply polarity protection circuit;

[0022] The two ground ends of the PLC output interface connector JP0 are connected in parallel to form a ground wire (VSS) receiving end, the two ground end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com