Method for measuring content of decabromodiphenyl oxide in plastics by liquid phase chromatography

A technology of decabromodiphenyl ether and liquid chromatography, which is applied in the field of rapid detection of typical brominated flame retardants, can solve the problems of poor spectrum quality, long solvent extraction time, and difficult to quantify accurately, achieving high applicability, Effect of shortening sample processing time and avoiding yield problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

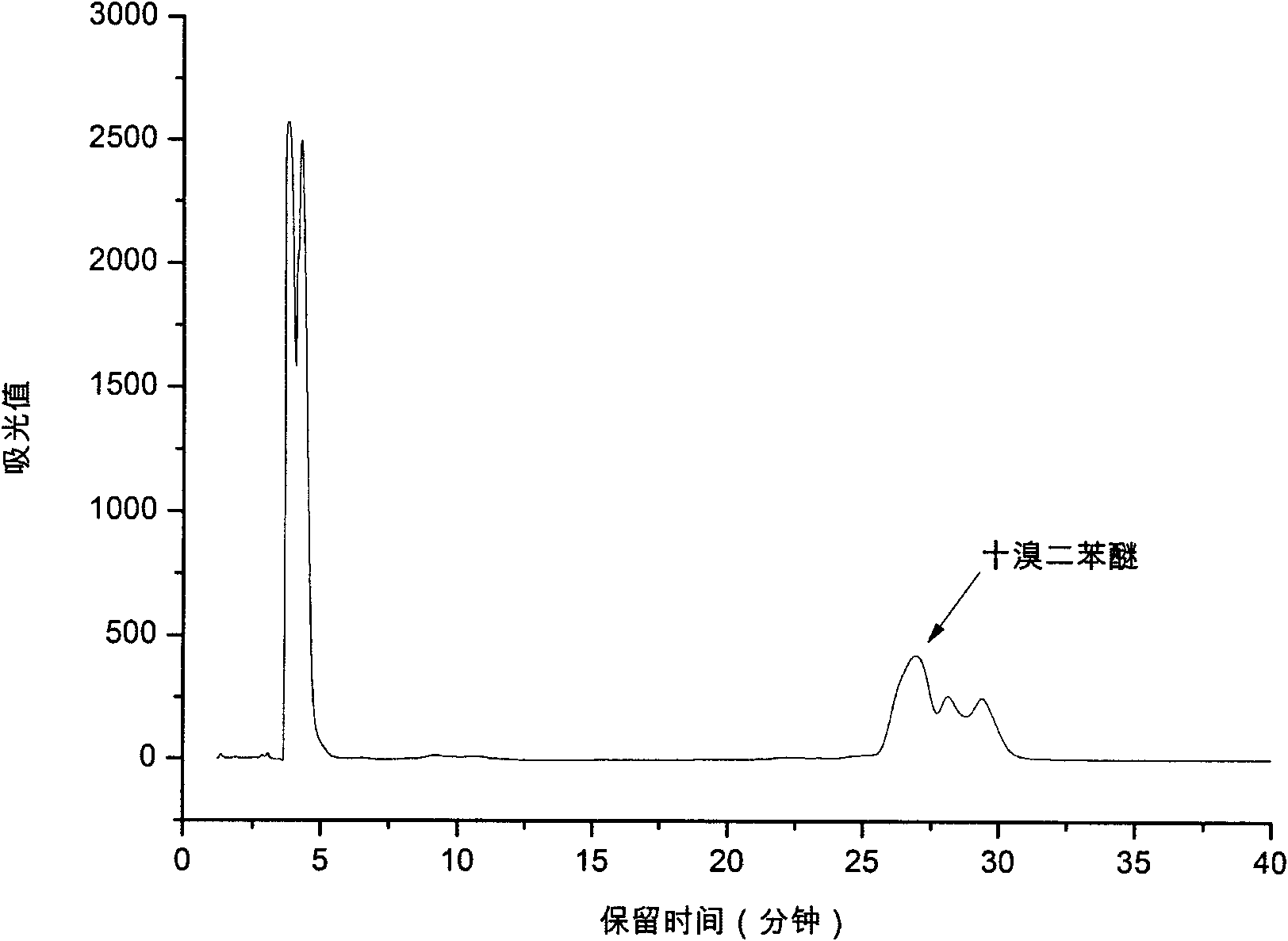

[0030] Embodiment 1: Decabromodiphenyl ether content determination in high impact polystyrene

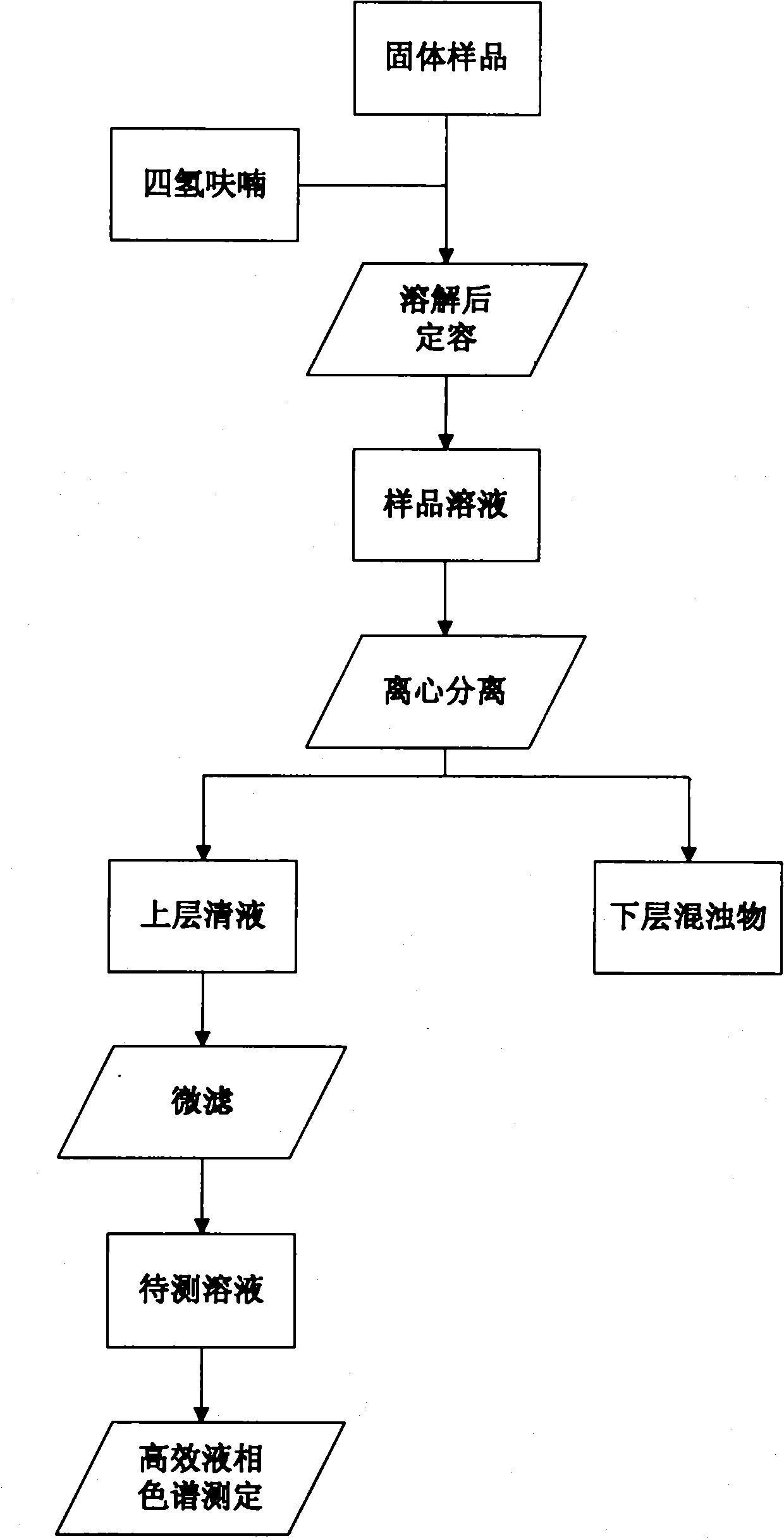

[0031] Such as figure 1 Shown, the present invention measures the flow process of the content of decabromodiphenyl ether in high-impact polystyrene plastics. The solid sample is made of a high-impact polystyrene plastic masterbatch of a domestic brand PS-I and a decabromodiphenyl ether industrial product, which is mixed evenly by banburying, and the mass content of decabromodiphenyl ether is 10.3%. After the above solid sample was crushed into a solid powder with an average size of 0.5 mm by a blade type solid crusher, 0.5821 g of the solid powder was weighed with an analytical balance and placed in a 150 mL Erlenmeyer flask, and then about 50 mL of analytically pure tetrahydrofuran solvent was added. The above solvent and solid sample powder were magnetically stirred for 10 minutes to completely dissolve the solid sample in the tetrahydrofuran solvent. Transfer the above liquid i...

Embodiment 2

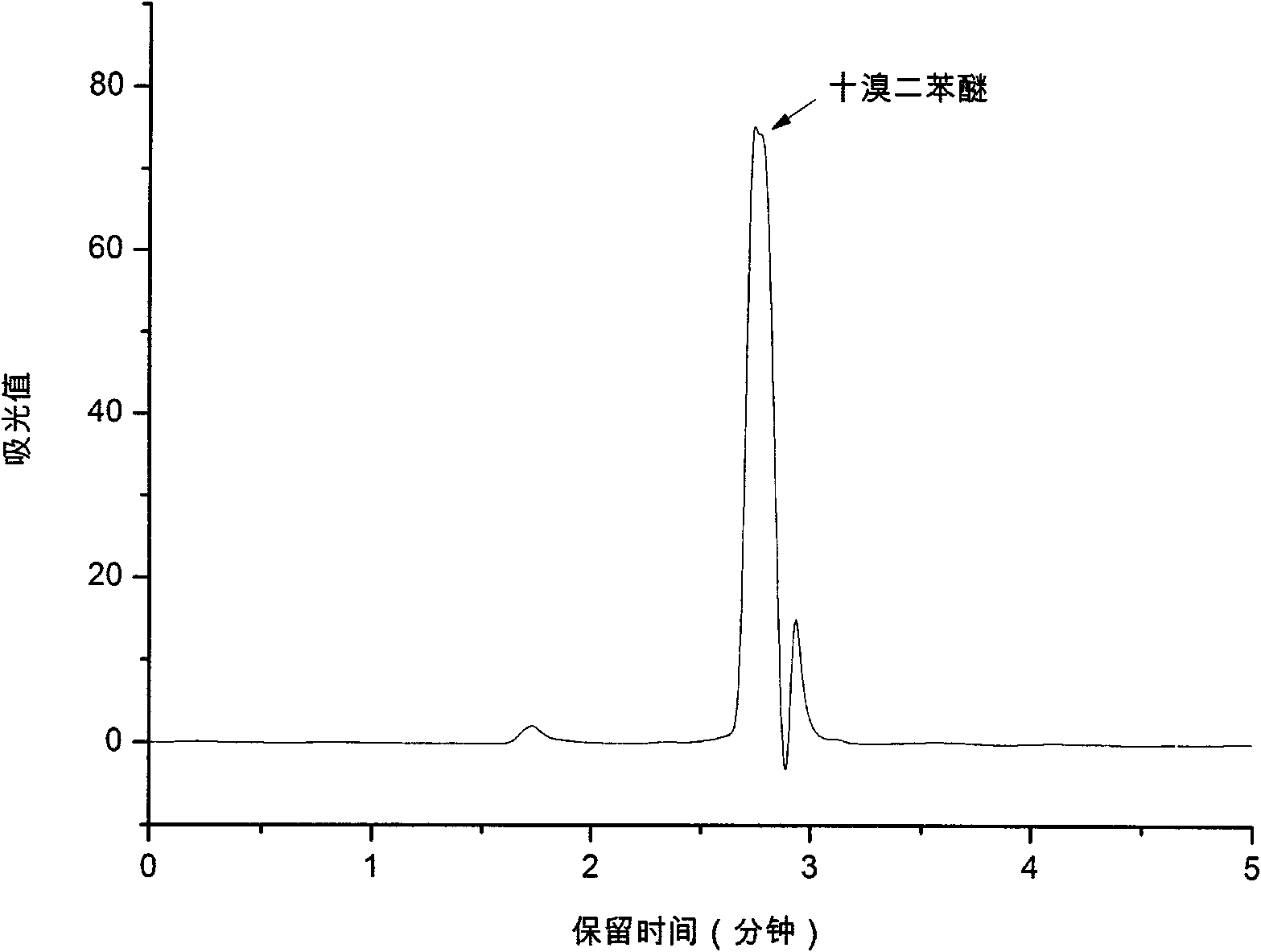

[0035] Embodiment 2: Decabromodiphenyl ether content determination in waste TV casings

[0036] The invention is used to determine the content of decabromodiphenyl ether in an imported waste TV casing. After the solid sample is washed and dried, it is crushed into solid powder with an average size of 0.5 mm by a blade-type solid crusher, and 0.6522 g of the solid powder is weighed with an analytical balance and placed in a 150 mL conical flask, and then about 50 mL of analytically pure tetrahydrofuran solvent is added. . The above solvent and solid sample powder were magnetically stirred for 10 minutes to completely dissolve the solid sample in the tetrahydrofuran solvent. Transfer the above liquid into a 100mL volumetric flask and dilute with tetrahydrofuran to obtain a sample solution.

[0037] Take about 3mL of the sample solution and place it in a 5mL glass centrifuge tube, and centrifuge at a speed of 3000rpm for 15 minutes to separate the sample solution into a superna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com