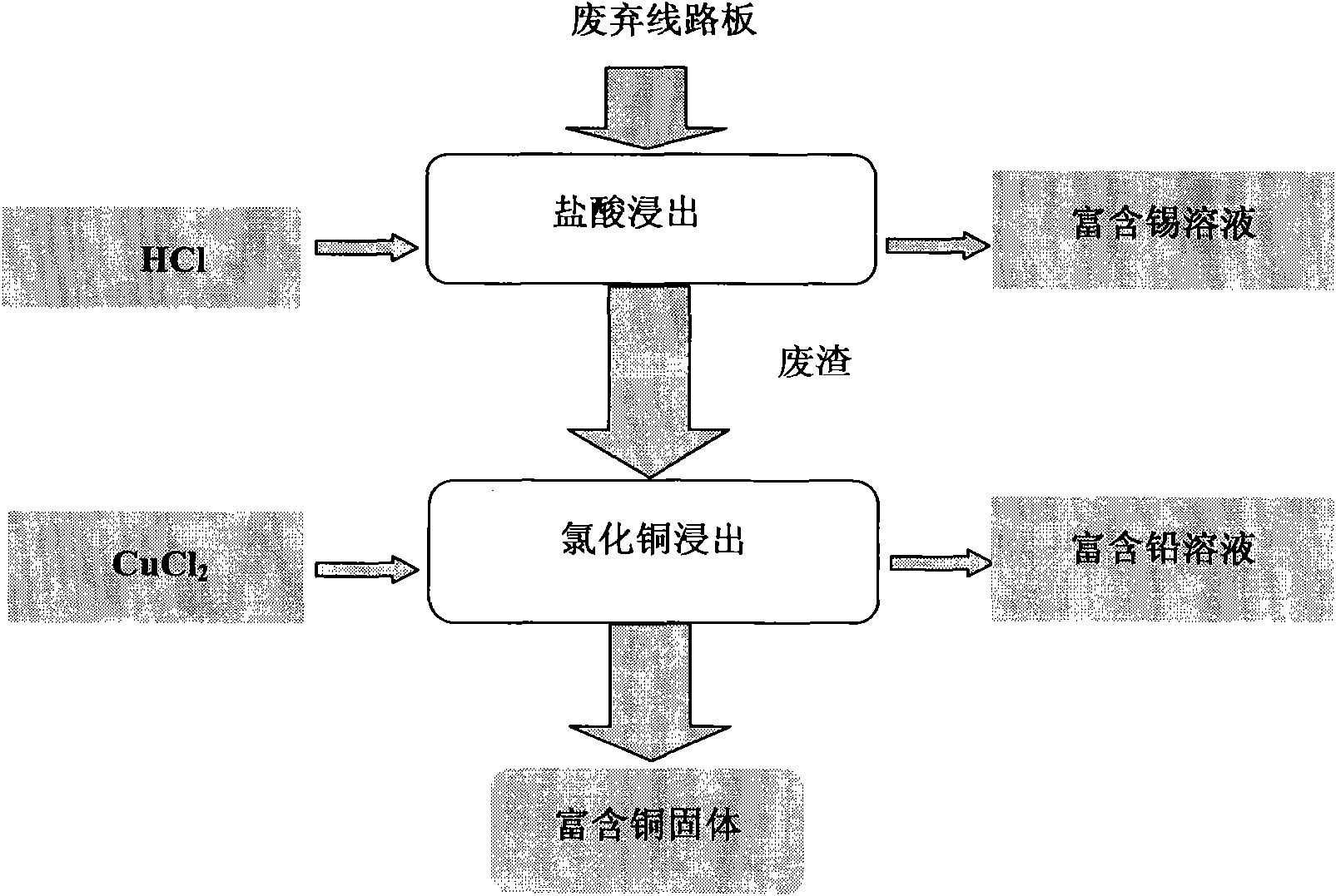

Method for selectively leaching and separating tin, lead and copper from waste circuit board

A waste circuit board, selective technology, applied in the direction of process efficiency improvement, etc., can solve the problems of high energy consumption, high equipment requirements, high processing costs, etc., and achieve the effect of saving operating costs and saving separation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Use waste circuit boards with an average particle size of 0.5mm and containing copper (5000mg / kg), tin (1000mg / kg) and lead (1000mg / kg) as raw materials, and use 0.5mol / L hydrochloric acid as the leaching agent to extract The temperature is 50°C, the leaching rate is 10 minutes, the leaching rate of copper is less than 0.06%, the leaching rate of tin is more than 91%, and the leaching rate of lead is less than 1%.

[0022] 2) Using hydrochloric acid leaching residue as raw material, using 0.005mol / L copper chloride as leaching agent, leaching temperature is 45°C, leaching for 300 minutes, lead leaching rate > 97%.

Embodiment 2

[0024] 1) Use waste circuit boards with an average particle size of 50mm and containing copper (70000mg / kg), tin (8000mg / kg) and lead (20000mg / kg) as raw materials, use 2.0mol / L hydrochloric acid as the leaching agent, and the leaching temperature leaching for 30 minutes at 35°C, copper leaching rate 93%, lead leaching rate < 0.4%.

[0025] 2) Using hydrochloric acid leaching residue as raw material, using 0.03mol / L copper chloride as leaching agent, leaching temperature is 50°C, leaching for 60 minutes, lead leaching rate > 97%.

Embodiment 3

[0027] 1) Use waste circuit boards with an average particle size of 100mm, containing copper (100000mg / kg), tin (12000mg / kg) and lead (10000mg / kg) as raw materials, use 2.5mol / L hydrochloric acid as the leaching agent, and the leaching temperature leaching for 300 minutes at 15°C, copper leaching rate 98%, lead leaching rate < 1.2%.

[0028] 2) Using hydrochloric acid leaching residue as raw material, using 0.05mol / L copper chloride as leaching agent, leaching temperature is 40°C, leaching for 10 minutes, lead leaching rate > 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com