Scratch resistant and shock proof propylene-ethylene block copolymerization polypropylene modified material

A technology of copolymerizing polypropylene and ethylene blocks, applied in the field of propylene-ethylene block copolymerized polypropylene modified materials, can solve the problems of poor impact performance, easy precipitation on the surface, reducing material strength and toughness, etc., and achieve excellent scratch resistance. The effect of wiping performance, broad market prospect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

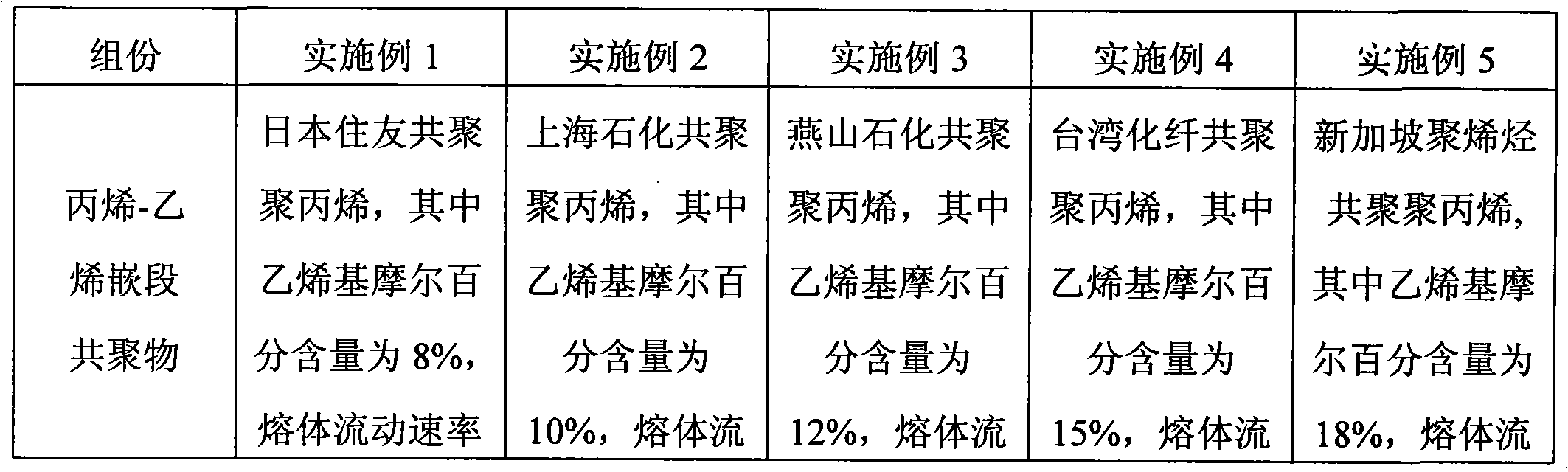

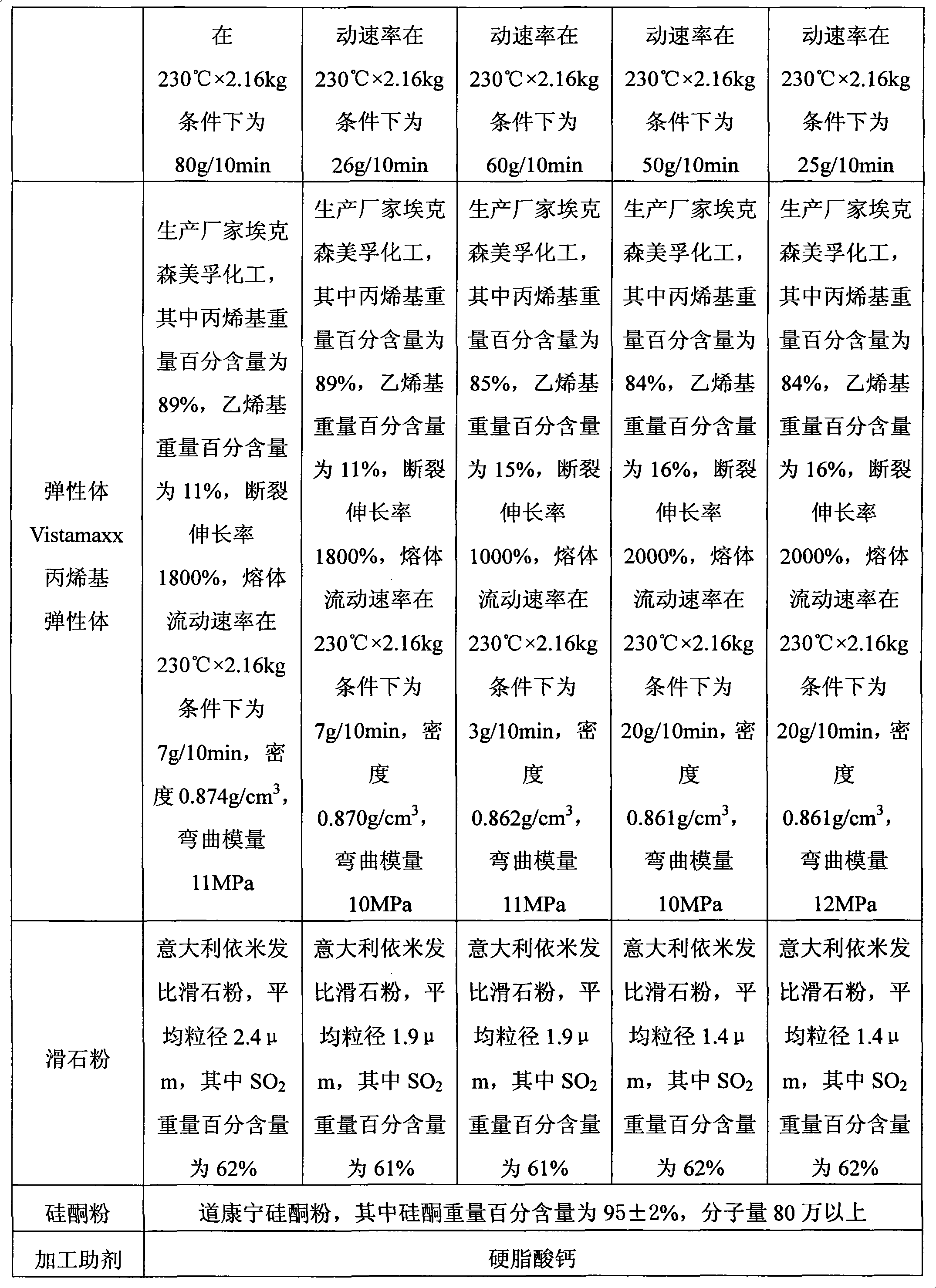

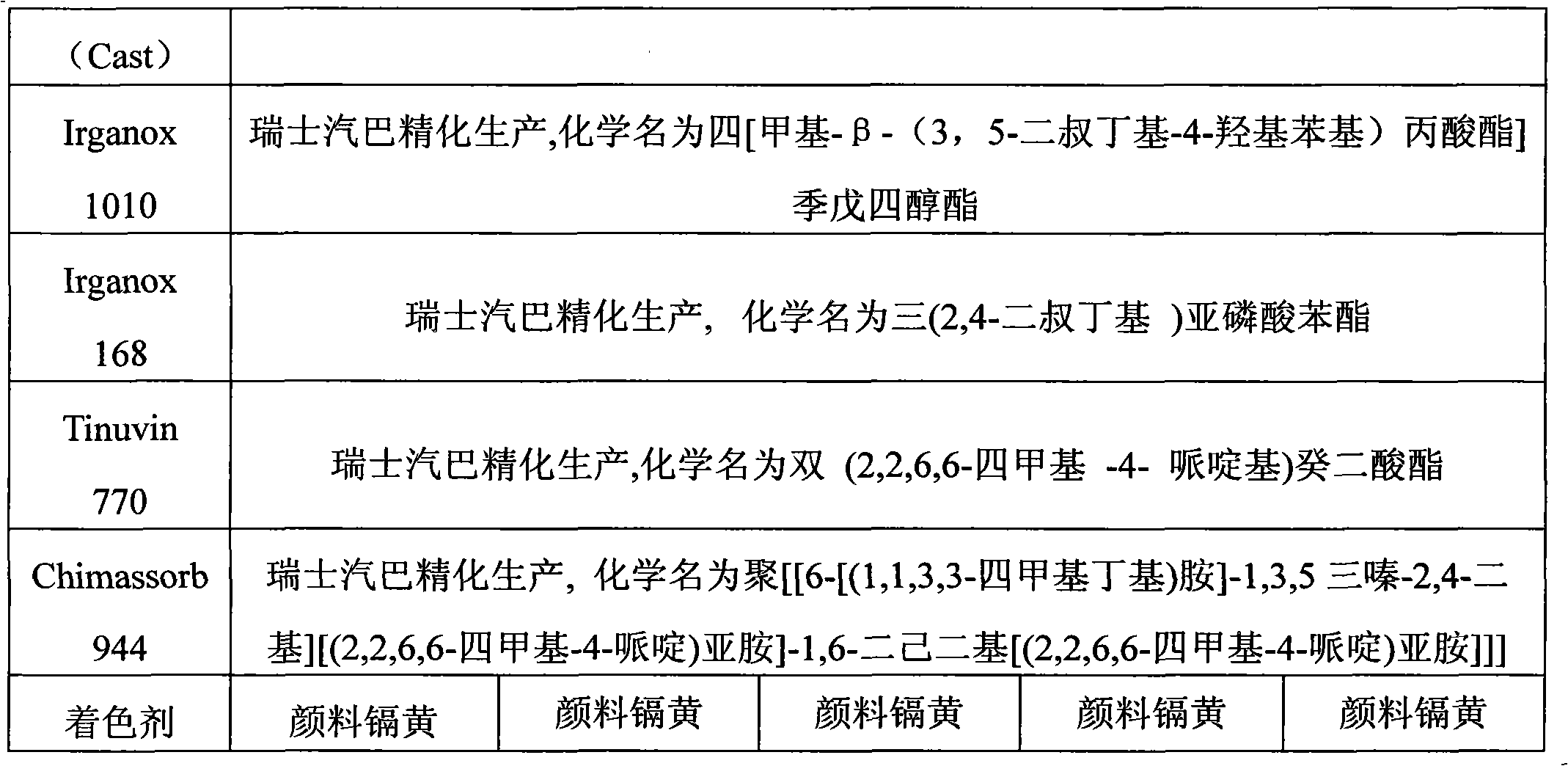

[0045] Propylene-ethylene block copolymerized polypropylene, talcum powder, elastomer, silicone powder, processing aids, stabilizers and other components were uniformly mixed in a mixer according to the proportions in parts by weight in Table 1. The mixed material is fed into the twin-screw extruder from the feeder. The temperature of the twin-screw extruder from the feeding section to the head is as follows: 190°C, 210°C, 220°C, 220°C, 220°C, 220°C, 220°C, the temperature of the die is: 210°C. After high-speed twin-screw (screw speed: 800r / min) shearing and mixing, extruding from the machine head, drawing, air cooling, pelletizing, drying and packaging, the propylene-ethylene block copolymer polypropylene modified material is obtained. finished product.

[0046] Table 1

[0047] Component

Example 1

Example 2

Example 3

Example 4

Example 5

Propylene-Ethylene Block Copolymerization

54Kg

61Kg

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com