Method for reducing SO2 content in exhaust gas in production of sulfuric acid

A technology of SO2 and exhaust gas, applied in the field of sulfuric acid, can solve problems such as equipment corrosion, corrosion, and small market demand, and achieve low maintenance costs, increase sulfuric acid output, and significant environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

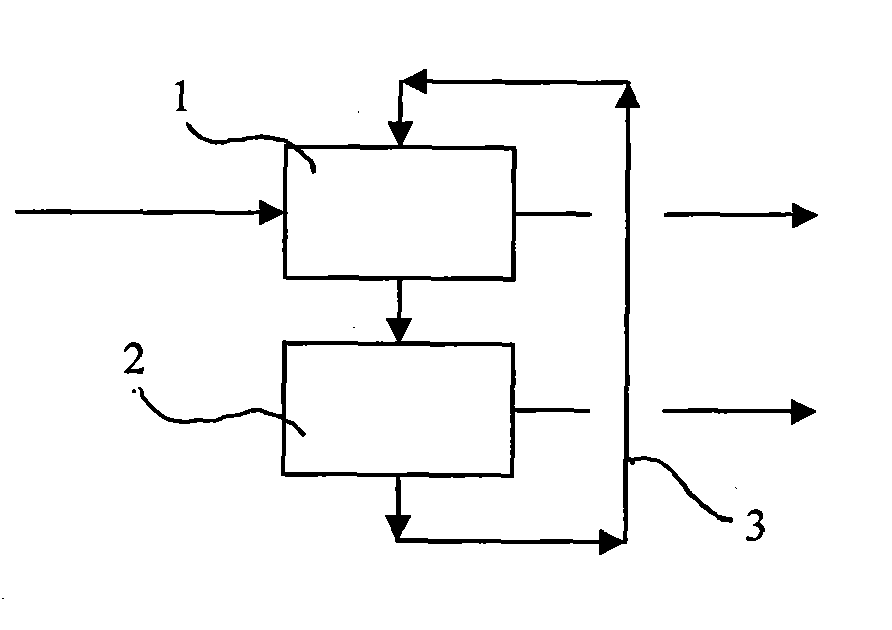

[0021] The sulfuric acid branch of Wengfu Phosphate Fertilizer Plant added a tail gas desulfurization device consisting of an adsorption tower and a desorption tower between the second acid absorption tower of the existing sulfuric acid plant and the tail gas discharge chimney, as a bypass line of the tail gas pipeline; the adsorption tower consists of two Cross-flow bed adsorption layer, a gas distribution chamber and two gas collection chambers, where each adsorption layer length × width × height = 13000mm × 1000mm × 15000mm, gas distribution chamber length × width × height = 13000mm × 2000mm × 15000mm, Length × width × height of each gas collection chamber = 13000mm × 1000mm × 15000mm; the desorption tower is a square vertical shell-and-tube heat exchanger, length × width × height = 49000mm × 2800mm × 12000mm, and the heat exchange tubes are arranged in a serpentine shape The steam heating tube and the heat exchange tube are φ19×3.8.

[0022] During production and operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com