Combination method of polymer carbon nanotube chromatographic column and ion chromatography single pump column switching technology

A technology for switching ion chromatography columns and single-pump columns, which is applied in the field of ion chromatography single-pump column switching, can solve problems such as long retention time and limited application range, and achieve the effects of accelerating analysis speed, saving analysis time, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the making process of polymer carbon nanotube composite chromatographic filler is as follows, and its steps are:

[0034] (1) Synthesize 1.8 μm monodisperse polystyrene seed by dispersion polymerization method earlier, monomer concentration is 20%, stabilizer concentration is 3%, initiator consumption is 4% of monomer, and reaction medium is 95% ethanol aqueous solution, The reaction temperature was 70°C, the stirring speed was 250 rpm, and the reaction time was 24 hours.

[0035] (2) 50 mg of multi-walled carbon nanotubes were oxidized with 200 mL of concentrated sulfuric acid / concentrated nitric acid=3:1 (v / v) mixed acid solution, ultrasonicated at 35° C. for 6 hours, washed until neutral and then dried. Then, monodisperse polystyrene-divinylbenzene-carbon nanotube composite microspheres with a crosslinking degree of 55% were prepared by seed swelling method. The concentration of the monomer is 10%, the content of carbon nanotubes accounts for 1% of the...

Embodiment 2

[0037] Example 2: The specific detection steps of polymer carbon nanotube composite chromatography and ion chromatography single-pump column switching are as follows:

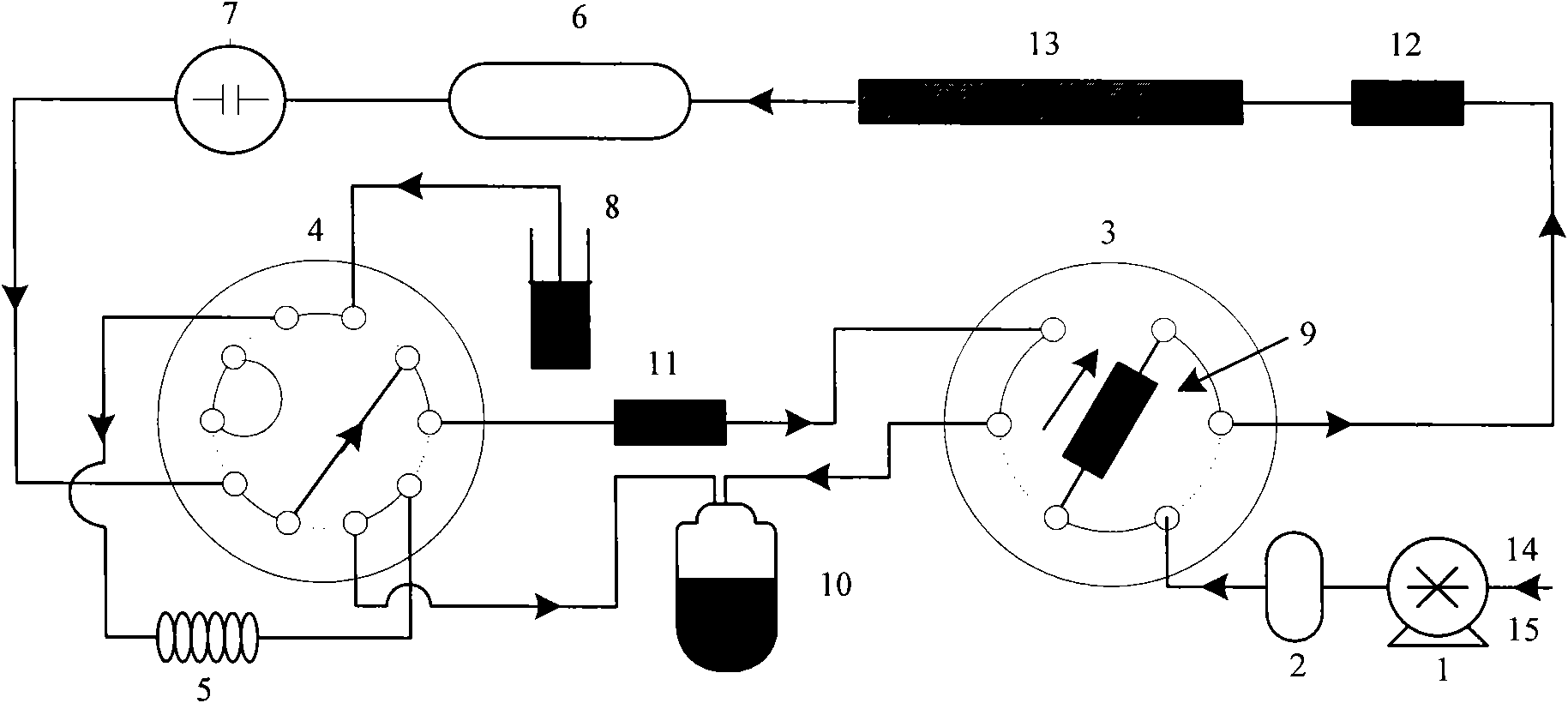

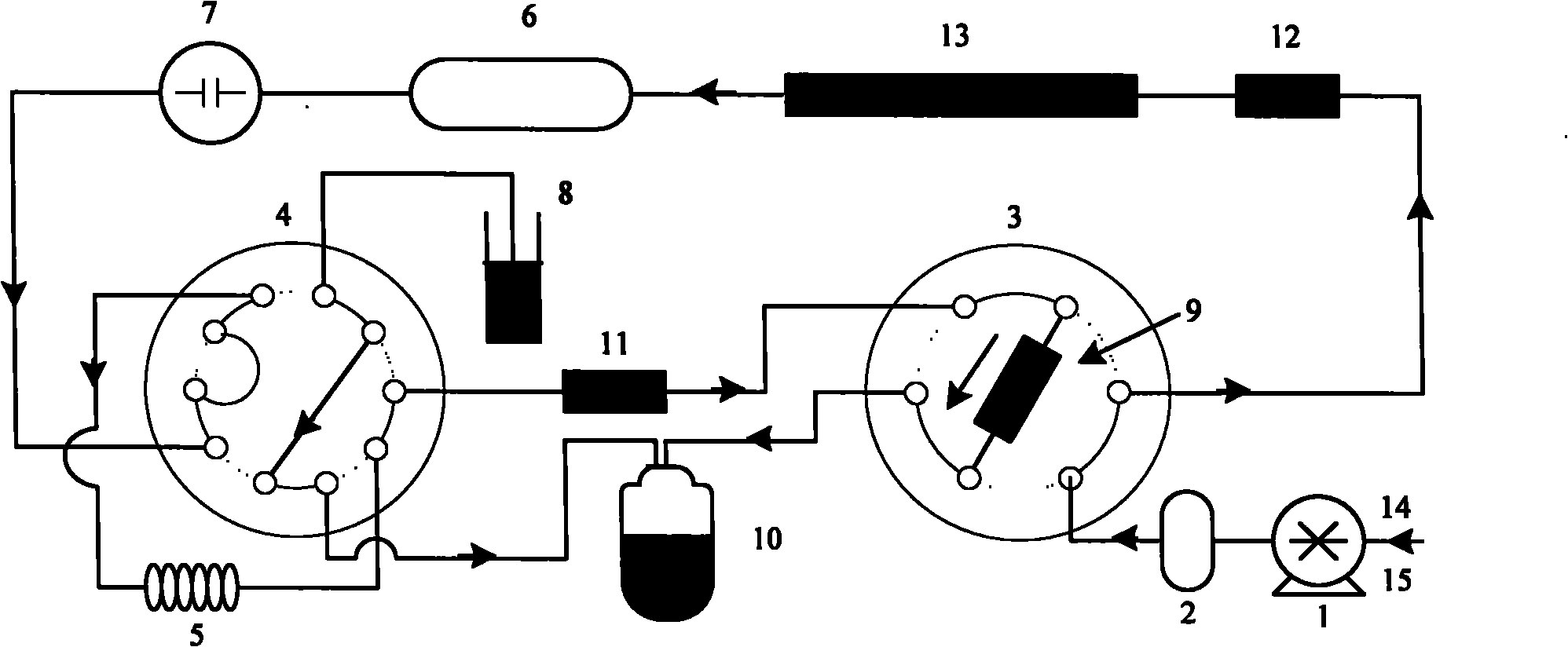

[0038] 1) Set the system according to figure 1 Well connected: the pump 1 is connected to the eluent generator 2, then the eluent passes through the six-way valve 3, connects the guard column 12 and the analysis column 13, passes through the suppressor 6, enters the detector 7 for detection, and then passes through the ten-way valve 4 is connected with the pretreatment column 11, and finally enters the waste liquid bottle 10. A 200 μL quantitative loop 5 is connected to the ten-way valve 4 , and the entire system is protected by nitrogen gas, 14 is a nitrogen cylinder, and a concentration column 8 is connected to the six-way valve 3 . After pump 1 was filled with mobile phase, it was turned on at a flow rate of 0.5 mL / min. The nitrogen gas 14 for protection is opened to a pressure of about 5 psi. Detector 7 ...

Embodiment 3

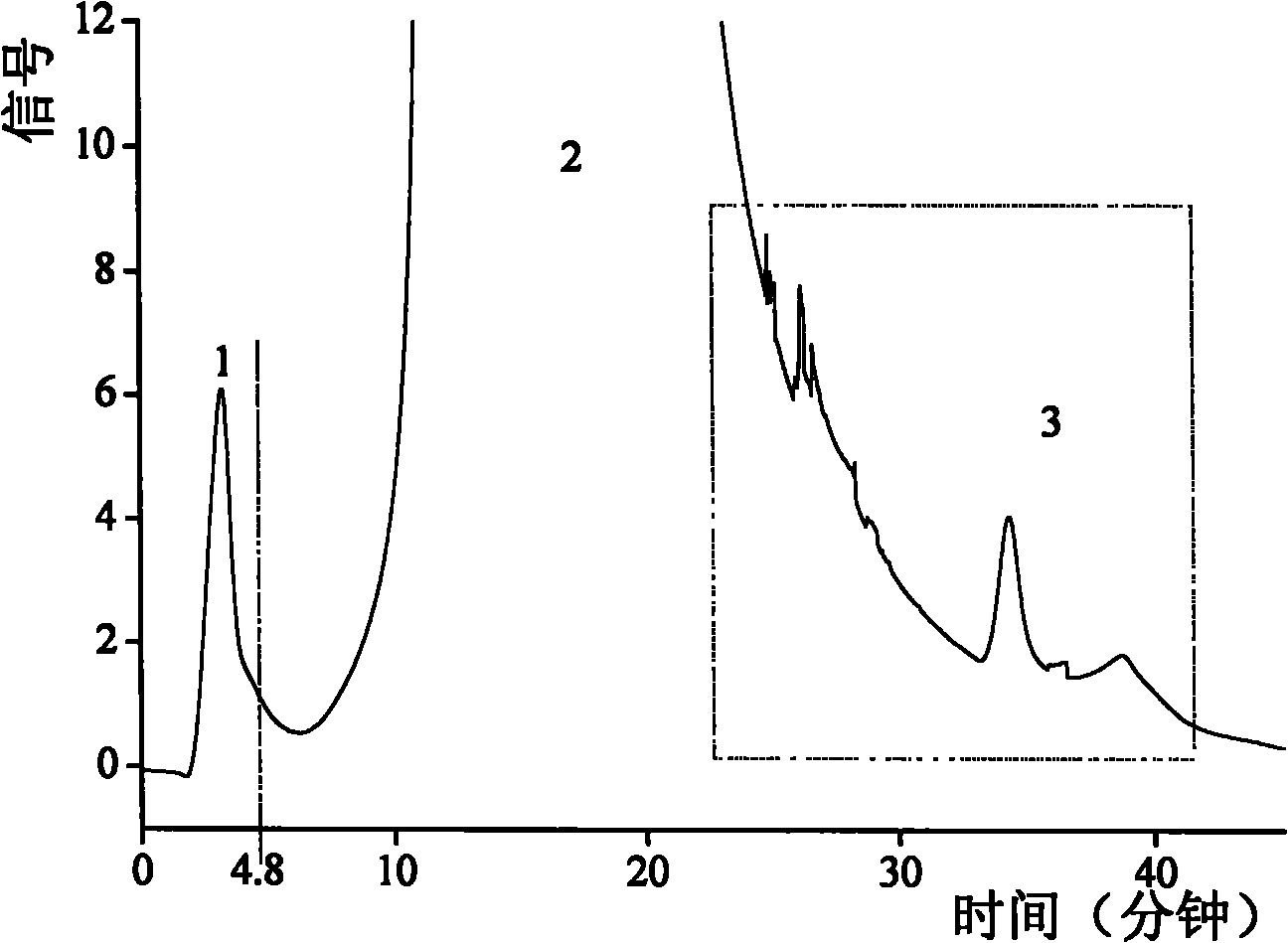

[0044] Embodiment 3: This embodiment is to analyze seven kinds of common inorganic anion mixed standard samples with column switching technology

[0045] Instruments used: ion chromatograph; chromatographic pump; conductivity detector; chromatographic workstation; one six-way valve; one ten-way valve; high-purity nitrogen cylinder; analytical column; guard column; enrichment column; 200 μL injection volume; electrochemical Self-regenerating suppressor.

[0046] Pretreatment column: use the polymer carbon nanotube composite filler in Example 1 to fill in a 4.6×150mm stainless steel column.

[0047] Eluent: H 2 O, KOH eluent generator concentration: 18mM, suppressor current: 90mA, flow rate 0.65mL / min.

[0048] Analysis steps:

[0049] (1) Baseline surveying and mapping

[0050] The eluent is pumped into the chromatographic separation column to achieve equilibrium, and the eluent output from the chromatographic separation column is converted into an electrical signal by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com