Preparation method of ultrafine grained Ni-Al alloy

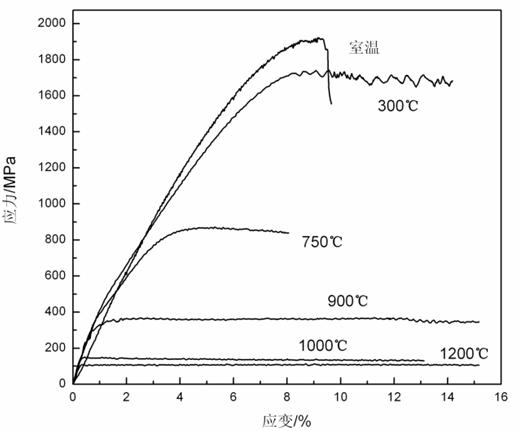

A technology of nickel-aluminum alloy and ultra-fine grain, which is applied in the field of alloy preparation, can solve the problems of low density and low mechanical properties of NiAl alloy, and achieve the effect of improving the strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

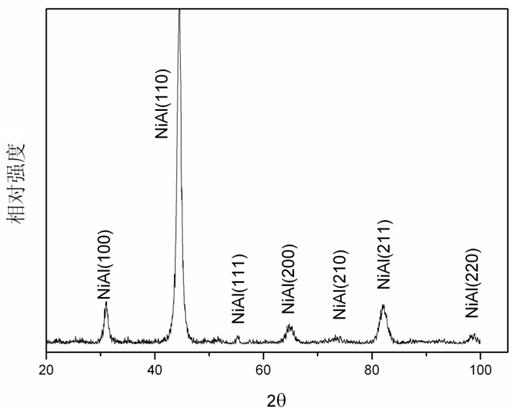

[0008] Specific Embodiment 1: The preparation method of ultra-fine-grained nickel-aluminum alloy in this embodiment is as follows: 1. Mechanical alloying: according to the ratio of nickel to aluminum atomic ratio of 1:1, nickel powder and aluminum powder are mixed and then added to a high-energy ball mill , and add absolute ethanol, the amount of absolute ethanol added is 3~5% of the volume fraction of nickel and aluminum mixed powder, and then under the protection of argon, ball mill at a speed of 280~320r / min, and each ball mill is 0.5 h, stop for 0.5h, the effective ball milling time is 18~24h, and the ball mill tank is cooled by circulating water to obtain completely alloyed nickel-aluminum alloy powder; 2. Vacuum hot pressing sintering: put the fully alloyed nickel-aluminum alloy powder into graphite mold, and then put the graphite mold into the vacuum hot-press sintering furnace, and vacuum the vacuum hot-press sintering furnace to 1.3×10 -2 Pa, and then heated to 1200~1...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the addition of absolute ethanol in step one is 4% of the volume fraction of nickel and aluminum mixed powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, ball milling is performed at a speed of 290-310 R / min. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com