Modified ultra-high molecular weight polyethylene (UHMWPE) and application thereof on centrifugal pump

An ultra-high molecular weight, high-volume polyethylene technology, applied in the field of modified ultra-high molecular weight polyethylene, can solve the problems of wear resistance, performance degradation, and increased production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

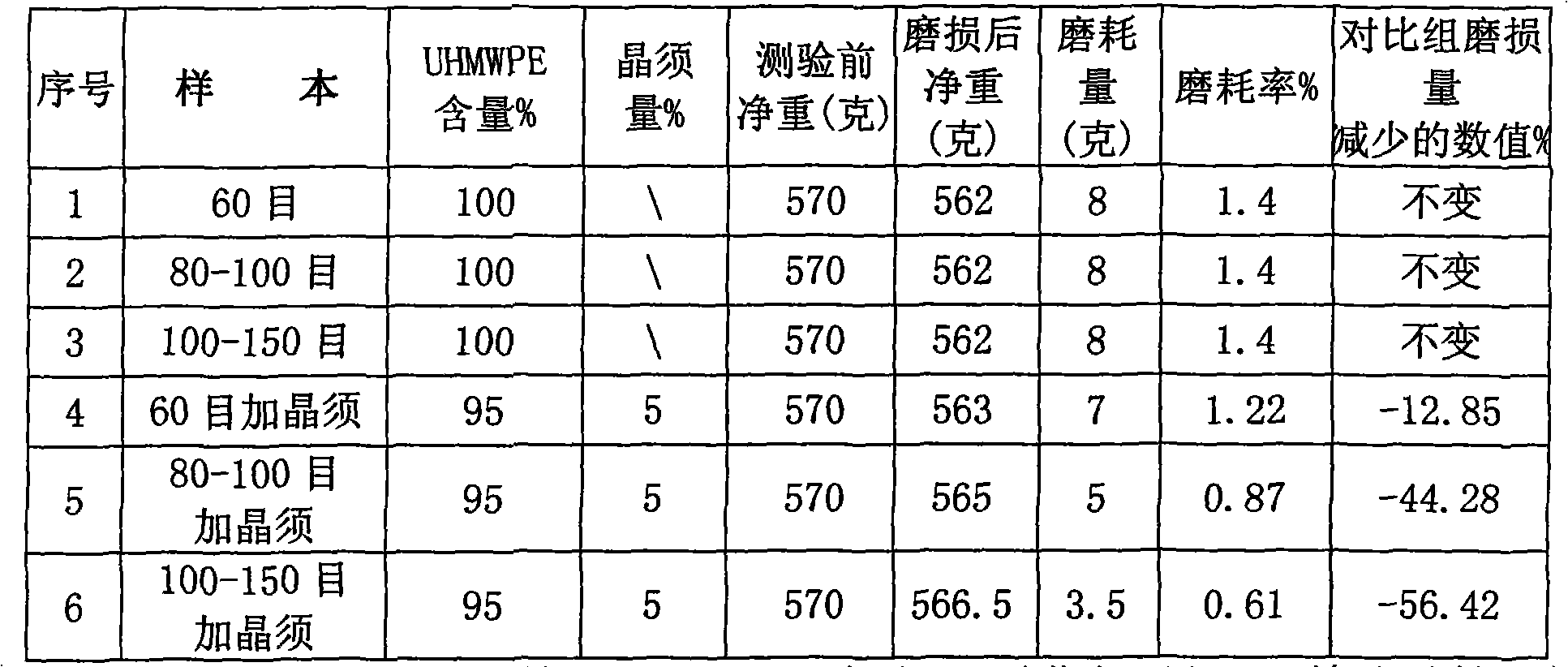

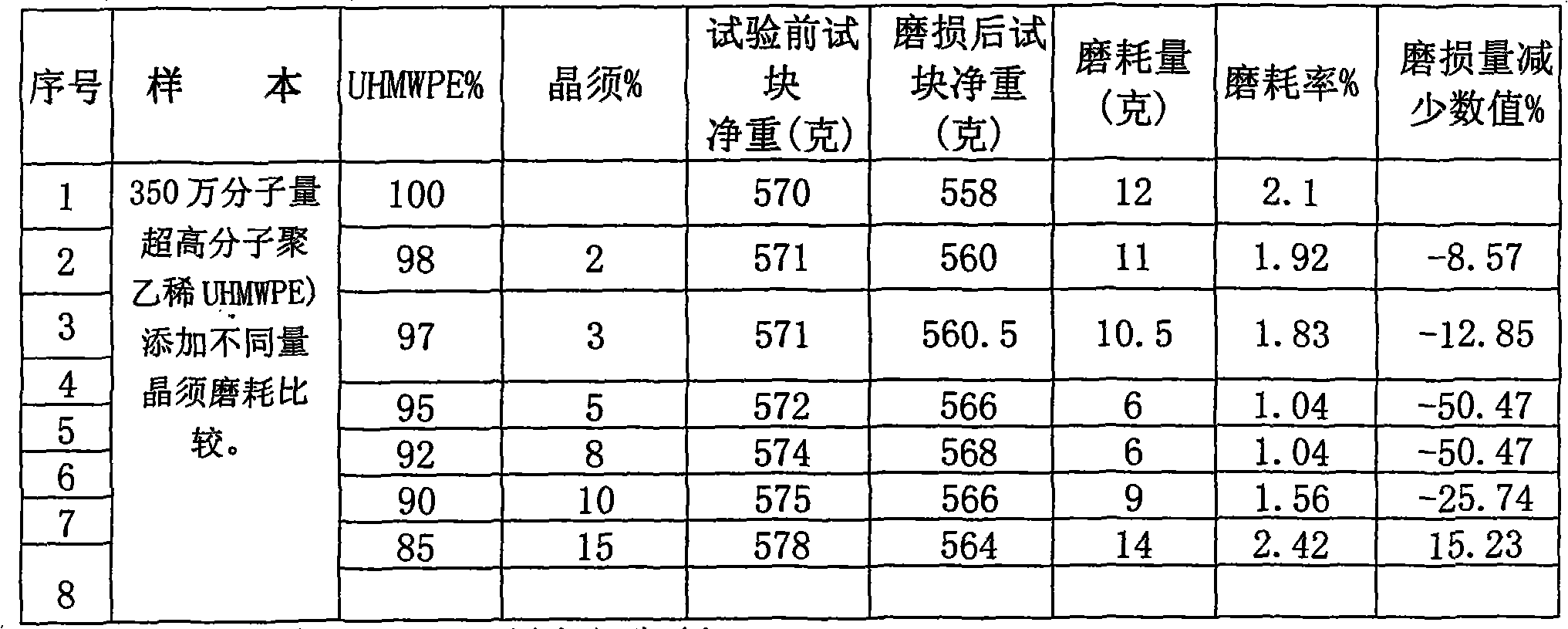

[0023] Embodiment 1: 95wt% of the commercially available molecular weight 5,000,000 40 order ultra-high molecular weight polyethylene is pulverized into 80 order fine powder, adds 5wt% potassium hexacarbonate whisker (average diameter 3 μm) through use temperature 180 ℃ of silane coupling agents , aspect ratio 10-30), mixed in a low-speed mixer for 5-15 minutes to obtain modified ultra-high molecular weight polyethylene powder. Potassium hexacarbonate whisker coupling treatment, with γ-aminopropyltriethoxysilane coupling agent (KH-550) of whisker weight 1-2wt%, by diluting with ethanol 1:50 times, spray on whisker , mix, and dry to get the potassium hexacarbonate whisker that coupling agent handles (also can adopt dilute coupling agent to soak processing). ;

[0024] Put the obtained modified UHMWPE powder into the outer mold of the metal volute of the centrifugal pump according to the usual lining molding method, and heat the belt mold until the mold temperature is 240-280°C...

Embodiment 2

[0025] Example 2: As in Example 1, wherein the UHMWPE has a molecular weight of 4 million and a fineness of 60 meshes. Take 3wt% silicone oil (based on the weight of UHMWPE) and add 1-5 times of ethanol to dilute it. Put the UHMWPE into a high-speed 6000-10000 rpm In the mixer, add diluted silicone oil while stirring, stir evenly, and dry; add 7wt% potassium hexacarbonate whiskers (coupling agent treatment is the same as above), and put the two into a low-speed mixer and mix for 5-10 minutes. The methods of the molded pump volute and the all-plastic pump volute are basically the same as those of the prior art, except that the constant temperature time is shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com