Method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation

A technology of shotcrete granulation and compound fertilizer, which is applied to fertilizer mixture, fertilization device, application and other directions, can solve the problems of unreasonable process setting, increased biuret generation, increased fertilizer production cost, etc. The effect of caking, reducing nitrogen loss, reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

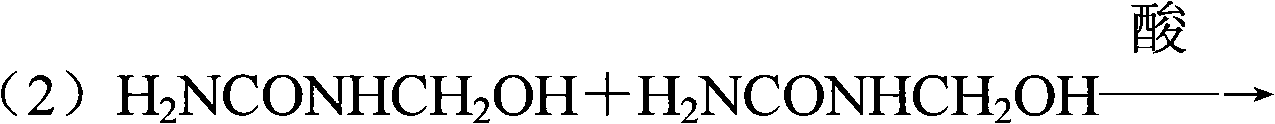

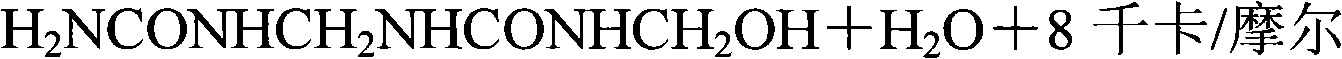

Method used

Image

Examples

Embodiment 1

[0033] Take 250 kg of solid urea, 60 kg of 40% formaldehyde solution, heat and stir to mix to 90°C, and mix the formed mixed slurry with 50 kg of 20% sulfuric acid in the pipeline, and transport the mixed slurry to drum granulation Machine granulation, feed 10 grams of ammonia while granulating, pre-place 340 kg of monoammonium phosphate, 250 kg of potassium chloride, gypsum powder (CaSO 4 ) 120 kg, the granulated fertilizer is cooled and sieved to obtain high-concentration granular nitrogen, phosphorus and potassium compound fertilizer, and the product specification is N-P 2 o 5 -K 2 O=15-15-15.

Embodiment 2

[0035] Take 400 kg of urea solution at the outlet of the second-stage evaporator of the urea plant, with a concentration of 99.7%, mix it with 100 kg of formaldehyde solution with a concentration of 50% in the pipeline, and then mix it with 40 kg of sulfuric acid with a concentration of 80%. The slurry is directly sprayed on the solid material in the drum granulator. The solid material should be crushed in advance until the particle size is less than 2mm. The solid material includes 150 kg of diammonium phosphate, 300 kg of potassium sulfate, 30 kg of talcum powder, and 1.5 kg of zinc sulfate. At the same time, 30 kg of ammonia is fed into the granulation, and the granulated material is cooled and sieved to obtain a high-concentration nitrogen, phosphorus, and potassium compound fertilizer. The specification of the compound fertilizer is N-P 2 o 5 -K 2 O=23-7-15, the compound fertilizer can be used as a special fertilizer for tobacco, and the application effect is obvious.

Embodiment 3

[0037] Take 200 kg of urea solution at the outlet of the second-stage evaporator of the urea plant, with a concentration of 95.0%, and mix it with 80 kg of formaldehyde solution with a concentration of 45% in the pipeline, and then mix the mixed slurry with 40 kg of sulfuric acid with a concentration of 93%. The mixed slurry is sprayed on the mixture of 100 kg of monoammonium phosphate, 400 kg of ordinary calcium, 167 kg of potassium chloride, 10 kg of dolomite and 3 kg of borax in the drum granulator. 50 kg of ammonia is introduced, and the solid material should be crushed in advance until the particle size is less than 1mm. The granulated material is cooled and sieved to obtain a medium-concentration granular nitrogen, phosphorus, and potassium compound fertilizer. The product specification is N-P 2 o 5 -K 2 O=15-10-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com