Preparation method of modified solid acid catalyst and catalyst prepared by same

A solid acid catalyst and catalyst technology, applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., can solve acid residues, increase esterification activity, and temperature sensitivity limits the space for esterification activity improvement, etc. problem, to achieve high esterification catalytic activity and water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

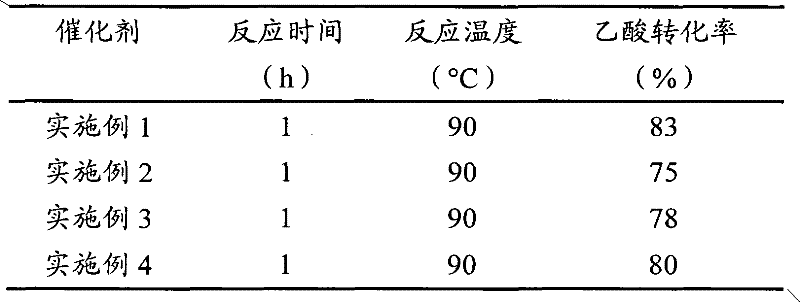

Embodiment 1

[0020] (1) Take 25.58g of tetra-n-butyl titanate and 20ml of ethanol in a 250ml beaker and stir evenly; take 20ml of ethanol, 1.04g of concentrated sulfuric acid and 4ml of distilled water, mix them evenly and put them in a separatory funnel, quickly drop them into the above beaker, Stir to obtain titanium sol. Aging the titanium sol at room temperature for 24 hours, drying at 110°C, and grinding through a 120-mesh sieve to obtain TiO 2 powder.

[0021] (2) According to SiO 2 with TiO 2 Weigh 4g SiO with a mass ratio of 2:3 2 , 6g TiO 2 , perform mechanical mixing, and add an appropriate amount of ethanol to continue stirring, stir and dry the above mixture to obtain a uniform SiO 2 with TiO 2 mixture, add 0.6g La 2 o 3 Powder, mixed evenly, impregnated with equal volume of sulfuric acid of 1 mol / L, stirred well and left for 5 hours, stirred and dried, transferred to muffle furnace for roasting at 400°C for 6 hours, the solid was naturally cooled, and the above solid w...

Embodiment 2

[0023] (1) Take 25.58g of tetra-n-butyl titanate and 20ml of ethanol in a 250ml beaker and stir evenly; take 20ml of ethanol, 1.04g of concentrated sulfuric acid and 4ml of distilled water, mix them evenly and put them in a separatory funnel, quickly drop them into the above beaker, Stir to obtain titanium sol; age the titanium sol at room temperature for 24 hours, dry at 110°C, and grind through a 120-mesh sieve to obtain TiO 2 powder.

[0024] (2) According to SiO 2 with TiO 2 Weigh 3g of SiO with a mass ratio of 3:7 2 , 7g TiO 2 , perform mechanical mixing, and add an appropriate amount of ethanol to continue stirring, stir and dry the above mixture to obtain a uniform SiO 2 with TiO 2 mixture, add 1g La 2 o 3 Powder, mixed evenly, impregnated with equal volume of sulfuric acid of 1 mol / L, stirred well and left for 5 hours, stirred and dried, transferred to muffle furnace for roasting at 400°C for 6 hours, the solid was naturally cooled, and the above solid was taken...

Embodiment 3

[0026] (1) Take 25.58g of tetra-n-butyl titanate, 20ml of ethanol in a 250ml beaker and stir evenly, take 20ml of ethanol, 1.04g of concentrated sulfuric acid and 4ml of distilled water, mix them evenly, put them in a separating funnel, and quickly drop them into the above beaker, Stir to obtain titanium sol; age the titanium sol at room temperature for 24 hours, dry at 110°C, and grind through a 120-mesh sieve to obtain TiO 2 powder.

[0027] (2) According to SiO 2 with TiO 2 Weigh 6g of SiO with a mass ratio of 6:4 2 powder, 4g TiO 2 Powder, mechanically mixed, and add an appropriate amount of ethanol to continue stirring, stir and dry the above mixture to obtain a uniform SiO 2 with TiO 2 mixture, add 0.8g La 2 o 3 The powder is impregnated with equal volume of sulfuric acid of 1 mol / L, stirred fully and left to stand for 5 hours, stirred and dried, transferred to a muffle furnace for roasting at 400°C for 6 hours, and the solid is cooled naturally. Carry out water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com