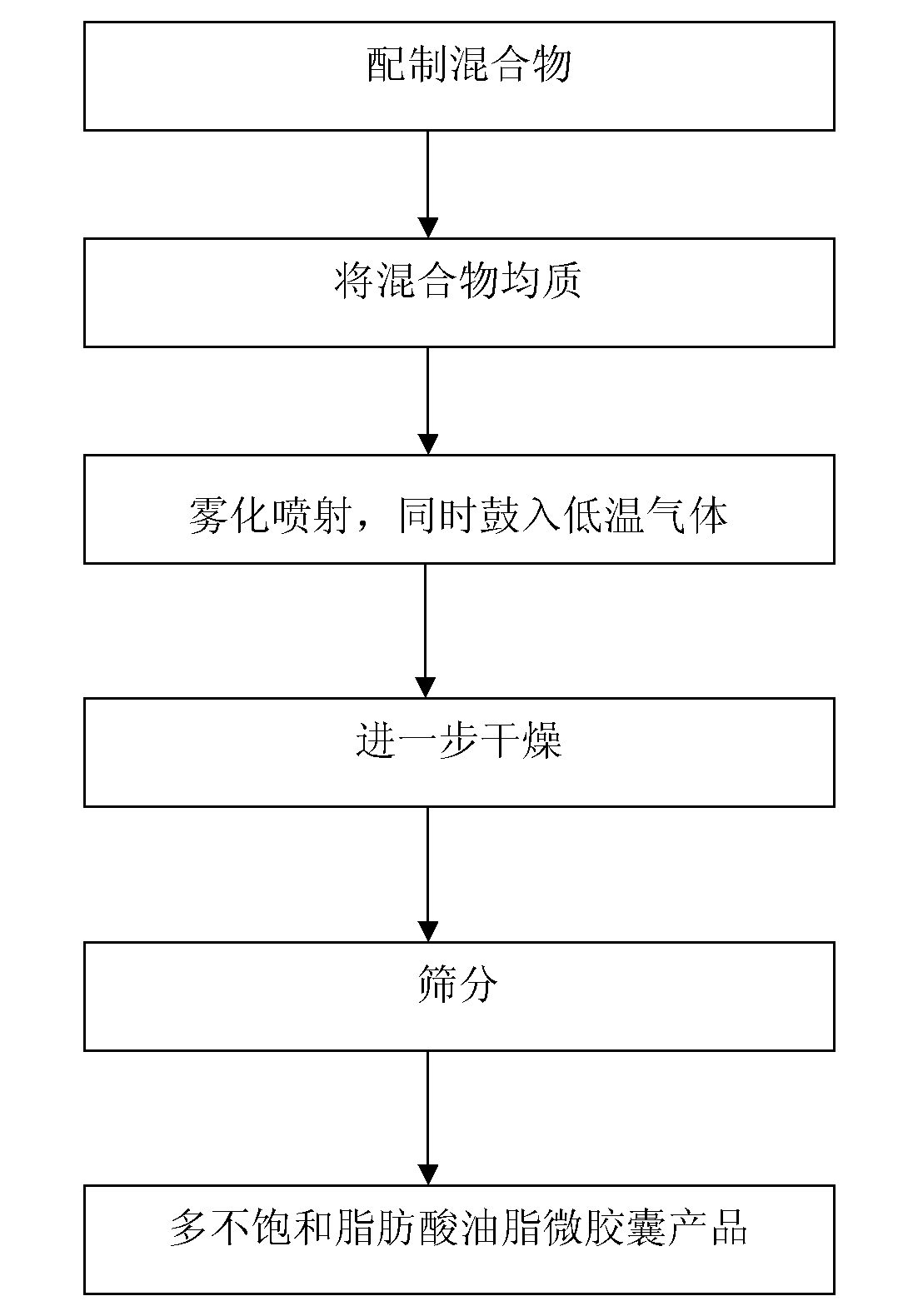

Spray freeze-drying preparation technology for polyunsaturated fatty acid oil microcapsule

An unsaturated fatty acid, spray freeze-drying technology, applied in the field of spray freeze-drying preparation technology, can solve the problems of affecting the yield of drying effect, easy inactivation of active ingredients, and high temperature required for evaporation, so as to improve product shelf life and stability. , The effect of improving oil embedding performance and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After mixing the ingredients in the above table at 60°C, use a homogeneous pressure of 40MPa to homogenize to form a uniform emulsion; then use a high-pressure pump to atomize the emulsion into droplets through an atomizing spray gun and spray it into the cooled spray drying equipment , wherein the atomization pressure of the pressure atomization is 1MPa, the temperature inside the spray drying equipment is -20°C, the bottom of the spray drying equipment is pre-installed with 2000g of maltodextrin, and at the same time blowing low-temperature gas to maintain the spray drying equipment The temperature inside is the set temperature -20°C, so that the atomized liquid droplets are frozen into solid particles in the spray drying equipment, and are covered by maltodextrin. After the emulsion is completely pressed into the spray drying equipment; Transfer the material to the vacuum freeze-drying equipment, adjust the absolute pressure in the vacuum drying equipment below...

Embodiment 2

[0032] After mixing the ingredients in the above table at 40°C, homogenize with a homogeneous pressure of 60MPa to form a uniform emulsion; then use a high-pressure pump to atomize the emulsion into droplets through an atomizing spray gun and spray it into the cooled spray drying equipment Among them, the atomization pressure of the pressure atomization is 1.5MPa, the temperature in the spray drying equipment is -30°C, and 100Kg of starch is pre-installed in the spray drying equipment, and low-temperature gas is blown in at the same time to maintain the temperature in the spray drying equipment. The temperature is set at -30°C, so that the atomized liquid droplets are frozen into solid particles in the spray drying equipment and covered by starch; at the same time, the solidified materials are continuously sent to the external fluidized bed In the process, the dry air at -30℃~-10℃ is used for boiling drying until the drying is completed. At the same time, 200kg of starch...

Embodiment 3

[0037]After mixing and emulsifying the ingredients in the above table at 80°C, homogenize under a homogeneous pressure of 80MPa to form a uniform emulsion; then use a pump to centrifugally atomize the emulsion into droplets and enter it into the cooled spray drying equipment , wherein the rotational speed of the centrifugal disc of the centrifugal atomization is 3000-4500rpm / min, the temperature in the spray drying equipment is -40°C, 150Kg of tricalcium phosphate is pre-added in the spray drying equipment, and low-temperature gas is blown in at the same time to maintain The temperature in the spray drying equipment is set at -40°C, so that the atomized liquid droplets are frozen into solid particles in the spray drying equipment and covered by tricalcium phosphate; at the same time, the solidified material is continuously sent to into the continuous vacuum freeze-drying equipment, vacuum freeze-drying for 10 hours, and at the same time, 200kg tricalcium phosphate is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com