Full solid-state laser for integrated laser diode intracavity pump

A laser diode and all-solid-state technology, applied in lasers, laser components, laser components, etc., can solve the problems of bulky solid-state lasers, low electro-optical conversion efficiency, and inability to meet energy conservation, and achieve high-efficiency beam quality and electro-optic conversion Efficiency improvement, increased stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

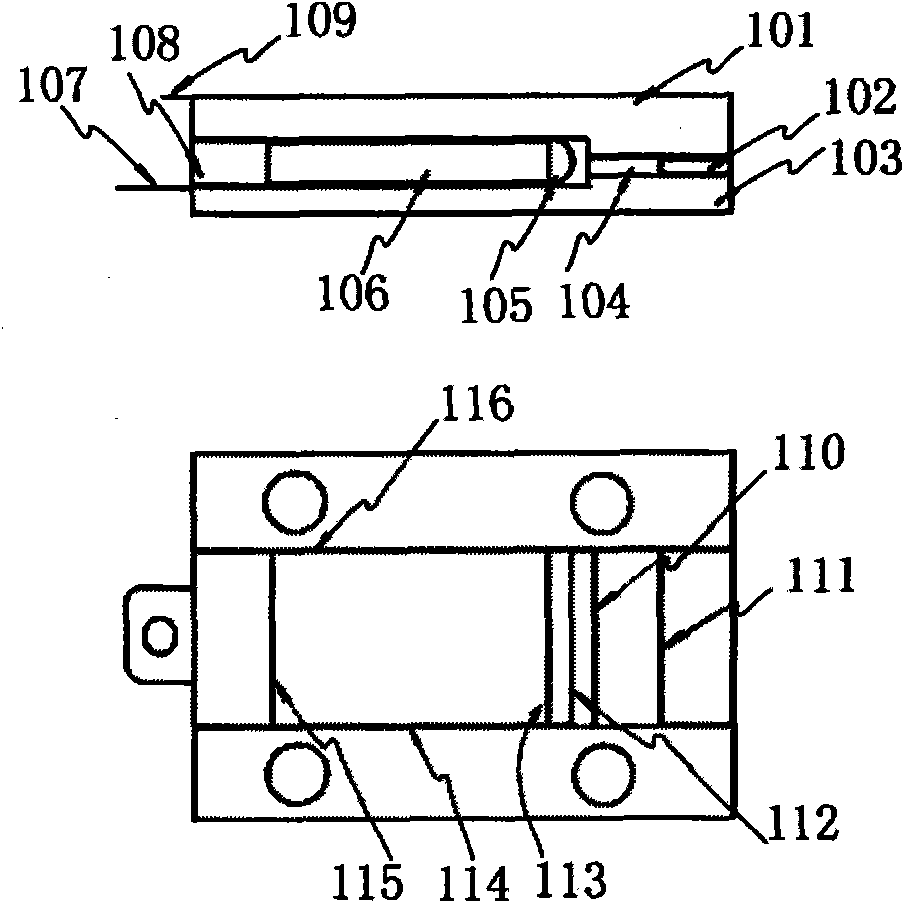

Embodiment 1

[0024] Such as image 3 As shown, the laser medium 106 is made of Nd:YAG crystal strip 301. The size of the crystal strip 301 is 1 mm thick, 8 mm wide, and 10 mm long. The doping concentration of Nd ions is 1%. On one end face of the crystal strip 301 116 is coated with a reflective film with a reflectivity greater than 99.7% to a wavelength of 1064nm, and the other end face 114 of the crystal slat 301 is coated with a partial reflective film with a reflectivity of 75% to a wavelength of 1064nm. An anti-reflection film with an emissivity of less than 0.2% to 808nm is coated, and a total reflection film with an emissivity of more than 99.7% to 808nm is coated on the other side 115 of the crystal slat 301 . The laser diode chip 104 is a chip with an AsGaAl multilayer quantum well structure. The working center wavelength of the laser diode chip is 808nm, the width of the light-emitting area is 0.2mm, and the distance between the light-emitting areas is 0.5mm. A total of 19 light-...

Embodiment 2

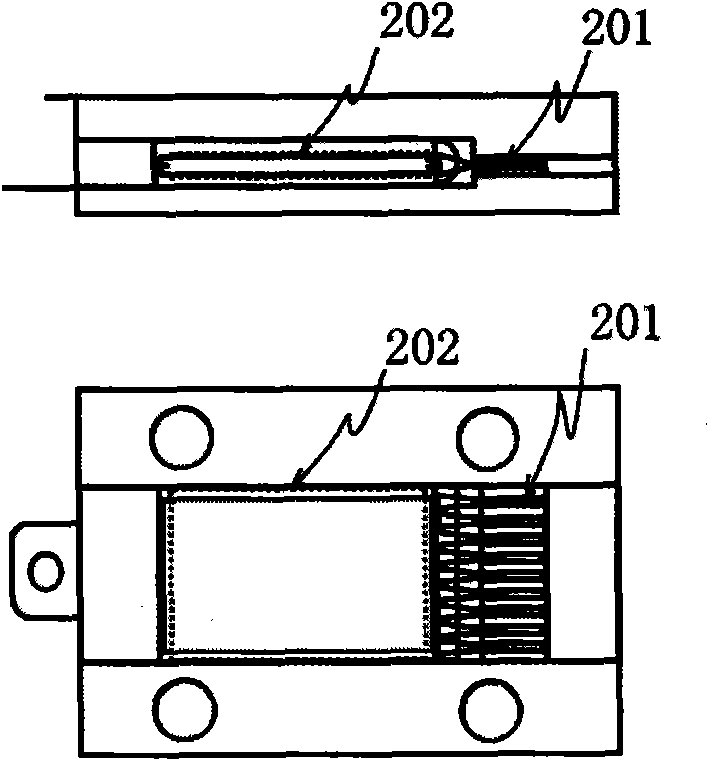

[0026] Such as Figure 4 As shown, the laser medium 106 in Embodiment 2 is made up of an optical fiber array 403, and the optical fiber array 403 is formed by side-by-side fusion splicing of four ytterbium-doped double-clad silica fibers with the outer cladding removed. The inner cladding diameter of the optical fiber is 500 microns, and the numerical aperture of the inner cladding is is 0.46, the core diameter of the ytterbium-doped double-clad fiber is 20 microns, the numerical aperture is 0.07, and the doping concentration of trivalent ytterbium ions in the core is 4000ppm. 4 double-clad silica fibers form a tapered fiber waveguide light cone by the method of parallel melting and tapering. When a 1.7V, 16A current is applied between the anode 107 and the cathode 109, the test result is that the laser of this embodiment The output power is 12W, the output wavelength is 1100nm, and the electro-optical conversion efficiency is 44%.

Embodiment 3

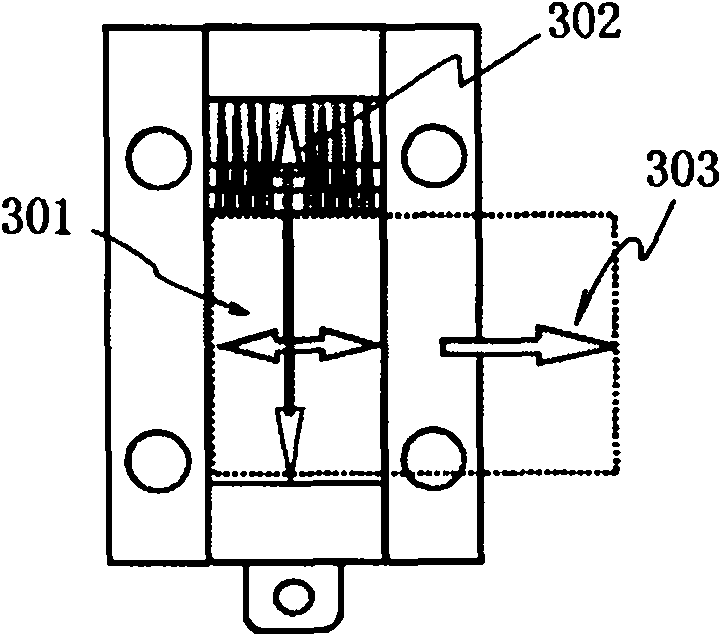

[0028] Multiple modules are connected in series to obtain higher power output. Such as Figure 5 As shown, in this embodiment, three optical fiber modules 501 are connected in series by means of optical fiber fusion. The structure of the optical fiber module 501 is as follows Figure 4 shown. The core diameter of the fiber at the fiber fusion point 502 is consistent with the numerical aperture, and the insertion loss is less than 0.1 dB. The output power of each module is 12W, the total output power of 3 modules connected in series is 36W, and the electro-optic conversion efficiency is still 44%.

[0029] In summary, the present invention is an integrated, miniature, high-efficiency and high-beam-quality high-power output all-solid-state laser. It greatly reduces the unit power-to-weight ratio of the current laser diode-pumped all-solid-state laser, and at the same time the electro-optic conversion efficiency has been greatly improved. Compared with the traditional all-soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com