Gutter snow melting plate

A technology for melting snow and gutters, which is applied to roof covering, program control in sequence/logic controllers, buildings, etc. It can solve problems such as roof collapse, gutter weight increase, and complicated construction, so as to prevent snow water from pouring back , good snow melting effect, simple laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

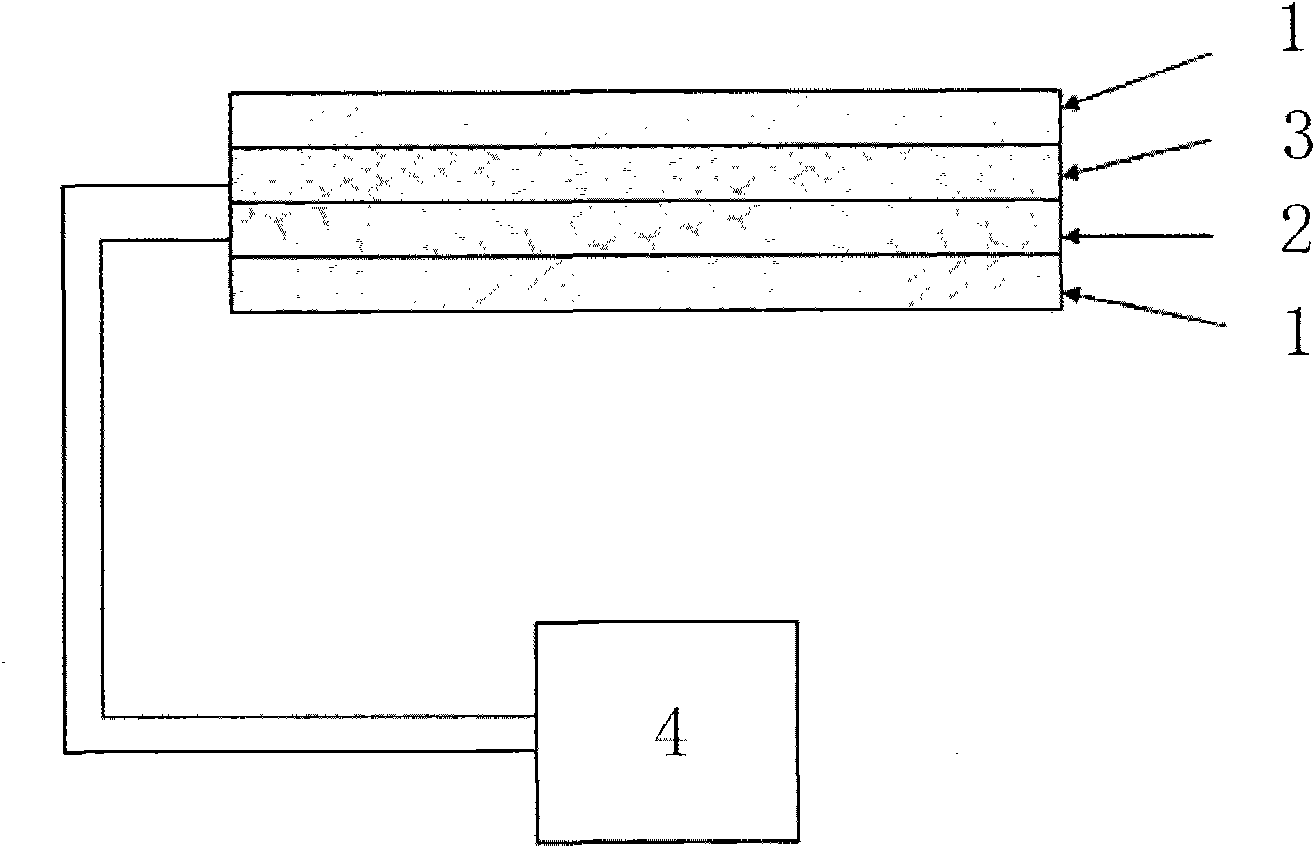

[0026] Such as figure 1 As shown, a gutter snow melting board is provided with a heat source layer 2 and an electric leakage protection layer 3 inside the gutter snow melting board protective layer 1, wherein the heat source layer 2 and the electric leakage protection layer 3 are respectively connected to the temperature control box 4 through a power line .

[0027] The material of the protective layer 1 is a polymer material, and its preparation method is as follows:

[0028] 1) masticating 40 parts of EPDM rubber and 10 parts of butyl rubber in proportion by weight;

[0029] 2) Then add 20 parts of carbon black, 15 parts of active rubber powder, 10 parts of naphthenic oil, 3 parts of zinc oxide, 1 part of stearic acid and 1 part of sulfur, fully mix, and then pour to the level In the template, use it after cooling under pressure.

[0030] The protective layer 1 made of this material has high tensile strength and tear strength, high elongation at break, good heat resistanc...

Embodiment 2

[0061] The material of the protective layer 1 is a polymer material, and its preparation method is as follows:

[0062] 1) masticating 30 parts of EPDM rubber and 5 parts of butyl rubber in proportioning by weight;

[0063] 2) Add 10 parts of carbon black, 10 parts of active rubber powder, 5 parts of naphthenic oil, 1 part of zinc oxide, 1 part of stearic acid and 1 part of sulfur, fully mix, and then pour to the level In the template, use it after cooling under pressure.

[0064] The heat source layer 2 is a resistive heating plate, and its preparation method is as follows:

[0065] 1) Mix 26 parts of dibutyl diformate, 12 parts of ethylenediamine pentahydrate and 58 parts of polytetrafluoroethylene resin in a proportion by weight, and then coat the template to form a base layer;

[0066] 2) Apply insulating varnish on the base layer and let it dry to form an insulating layer;

[0067] 3) Pour 7 parts of borax, 12 parts of insulating varnish, and 15 parts of graphite into ...

Embodiment 3

[0071] The material of the protective layer 1 is a polymer material, and its preparation method is as follows:

[0072] 1) by weight ratio, 50 parts of EPDM rubber and 15 parts of butyl rubber are masticated;

[0073] 2) Add 30 parts of carbon black, 20 parts of active rubber powder, 15 parts of naphthenic oil, 5 parts of zinc oxide, 5 parts of stearic acid and 5 parts of sulfur, fully mix, and then pour to the horizontal In the template, use it after cooling under pressure.

[0074] The heat source layer 2 is a resistive heating plate, and its preparation method is as follows:

[0075] 1) Mix 30 parts of dibutyl diformate, 14 parts of ethylenediamine pentahydrate and 60 parts of polytetrafluoroethylene resin in a proportion by weight, and then coat the template to form a base layer;

[0076] 2) Apply insulating varnish on the base layer and let it dry to form an insulating layer;

[0077] 3) Pour 11 parts of borax, 15 parts of insulating varnish, and 18 parts of graphite i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com