Double-component waterborne polyurethane glass transparent insulating coating

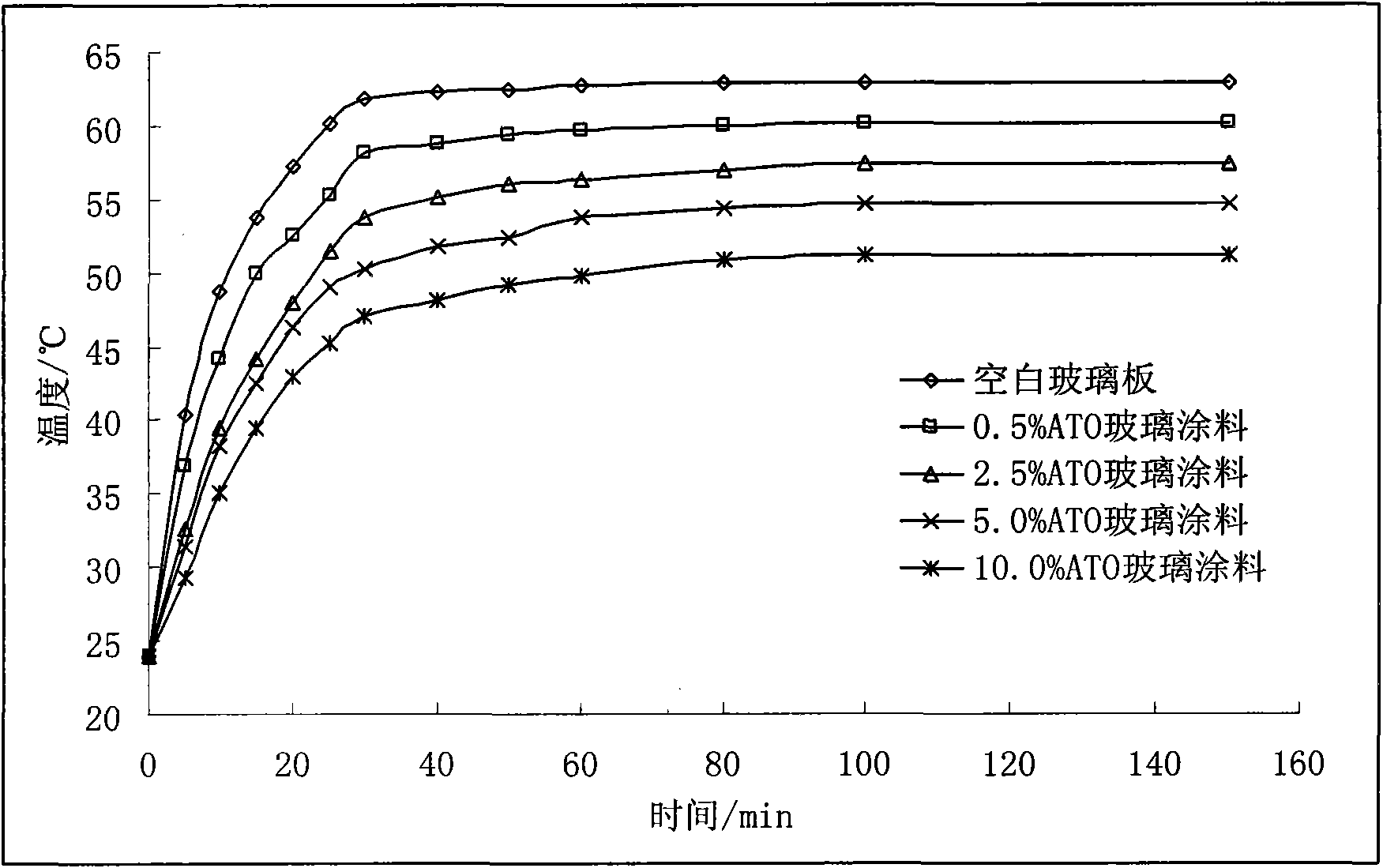

A technology for water-based polyurethane and heat-insulating coatings, applied in the field of coatings, can solve the problems of unsatisfactory performance of water-based glass heat-insulating coatings, and achieve the effect of improving low hardness and high infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

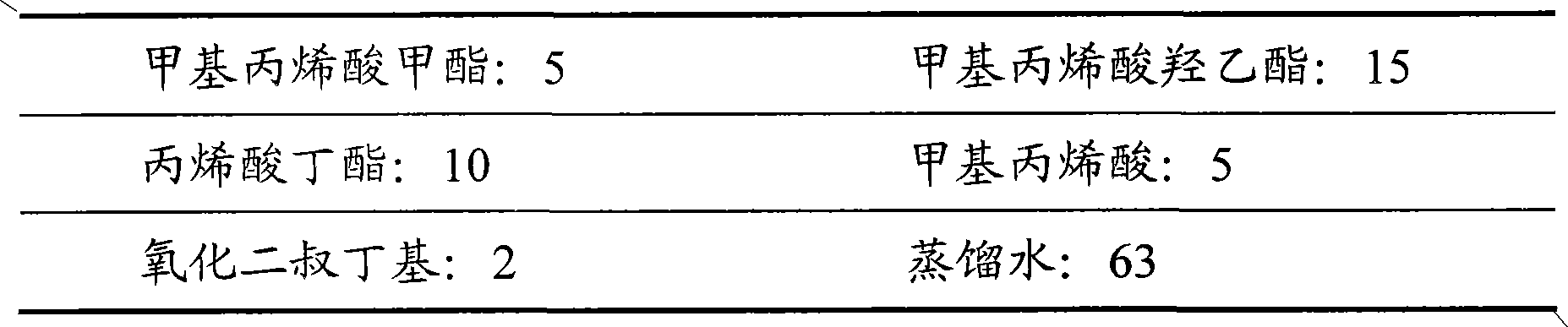

[0039] The specific implementation method: two-component water-based polyurethane glass transparent heat-insulating coating, its formula ratio is (percentage by weight):

[0040] Acrylic Dispersion:

[0041]

[0042] Put 50g of acetone into a four-neck flask equipped with a stirring blade and a condenser tube, raise the temperature to 80°C with a heating mantle, then add 5g of methyl methacrylate, 15g of hydroxyethyl methacrylate, 10g of butyl acrylate, and methacrylic acid Put the mixture of 5g and 1.5g di-tert-butyl peroxide into the constant pressure funnel, drop it into the four-necked bottle in 2-3h, add 0.5g di-tert-butyl peroxide after the dropwise addition and react for 2h, then lower the temperature to 60 ℃, neutralized with TEA to pH 7-8, and then added 63g of distilled water. The solvent was distilled off under reduced pressure to obtain a self-synthesized acrylic acid dispersion.

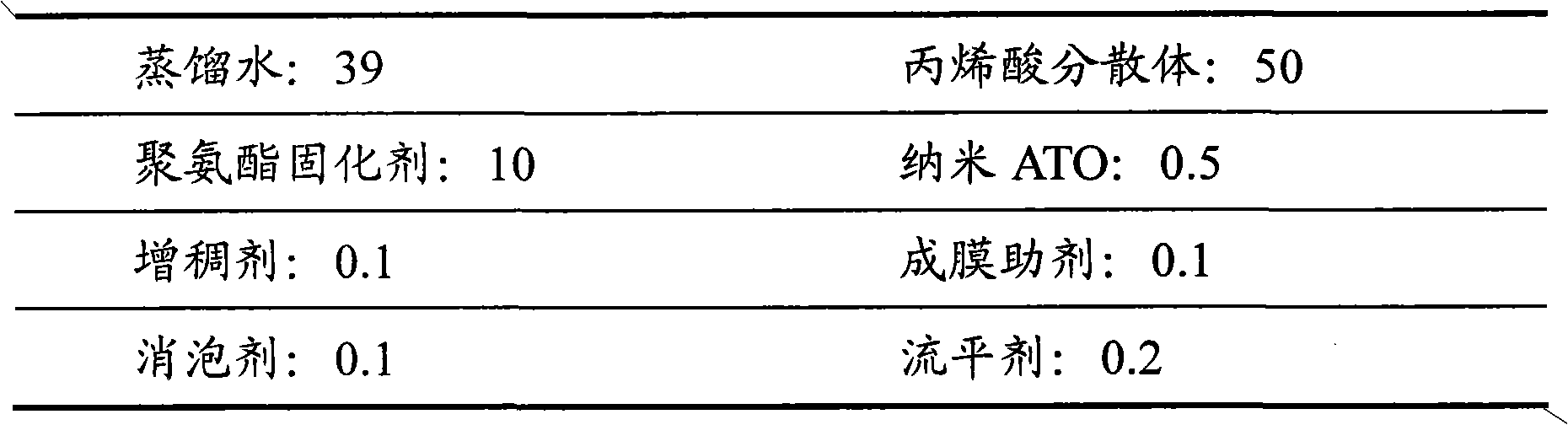

[0043] Thermal insulation coating:

[0044]

[0045] Take 39g of distilled ...

Embodiment 2

[0047] The specific implementation method: two-component water-based polyurethane glass transparent heat-insulating coating, its formula ratio is (percentage by weight):

[0048] Acrylic Dispersion:

[0049]

[0050] Put 50g of acetone into a four-necked flask equipped with a stirring blade and a condenser tube, raise the temperature to 80°C with a heating mantle, then add 10g of methyl methacrylate, 20g of hydroxyethyl methacrylate, 10g of butyl acrylate, and methacrylic acid Put the mixture of 10g and 4.5g of di-tert-butyl peroxide into a constant pressure funnel, drop it into a four-necked bottle in 2-3 hours, add 0.5g of di-tert-butyl peroxide after the addition and react for 2 hours, then cool down to 60 ℃, neutralized with TEA to pH 7-8, and then added 45 g of distilled water. The solvent was distilled off under reduced pressure to obtain a self-synthesized acrylic acid dispersion.

[0051] Thermal insulation coating:

[0052]

[0053] Take 7g of distilled water, ...

Embodiment 3

[0055] The specific implementation method: two-component water-based polyurethane glass transparent heat-insulating coating, its formula ratio is (percentage by weight):

[0056] Acrylic Dispersion:

[0057]

[0058] Put 50g of acetone into a four-necked flask equipped with a stirring blade and a condenser tube, raise the temperature to 80°C with a heating mantle, then add 10g of methyl methacrylate, 15g of hydroxyethyl methacrylate, 15g of butyl acrylate, methacrylic acid Put the mixture of 7g and 2.5g di-tert-butyl peroxide into the constant pressure funnel, drop it into the four-necked bottle in 2-3h, add 0.5g di-tert-butyl peroxide after the dropwise addition and react for 2h, then lower the temperature to 60 ℃, neutralized with TEA to pH 7-8, and then added 50 g of distilled water. The solvent was distilled off under reduced pressure to obtain a self-synthesized acrylic acid dispersion.

[0059] Thermal insulation coating:

[0060]

[0061] Take 20.7g of distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com