Low-radiation coating and preparation method thereof

A low-radiation, coating technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of heat loss, glass temperature rise, etc., to achieve the effect of enhanced thermal insulation, low infrared emissivity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

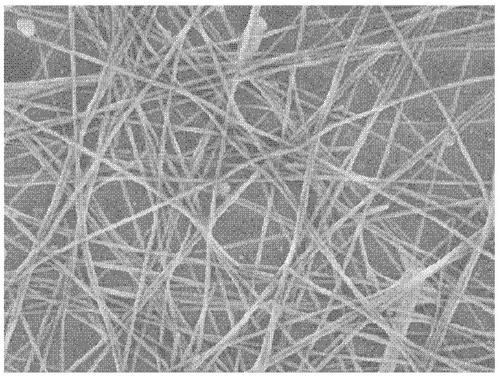

Image

Examples

preparation example Construction

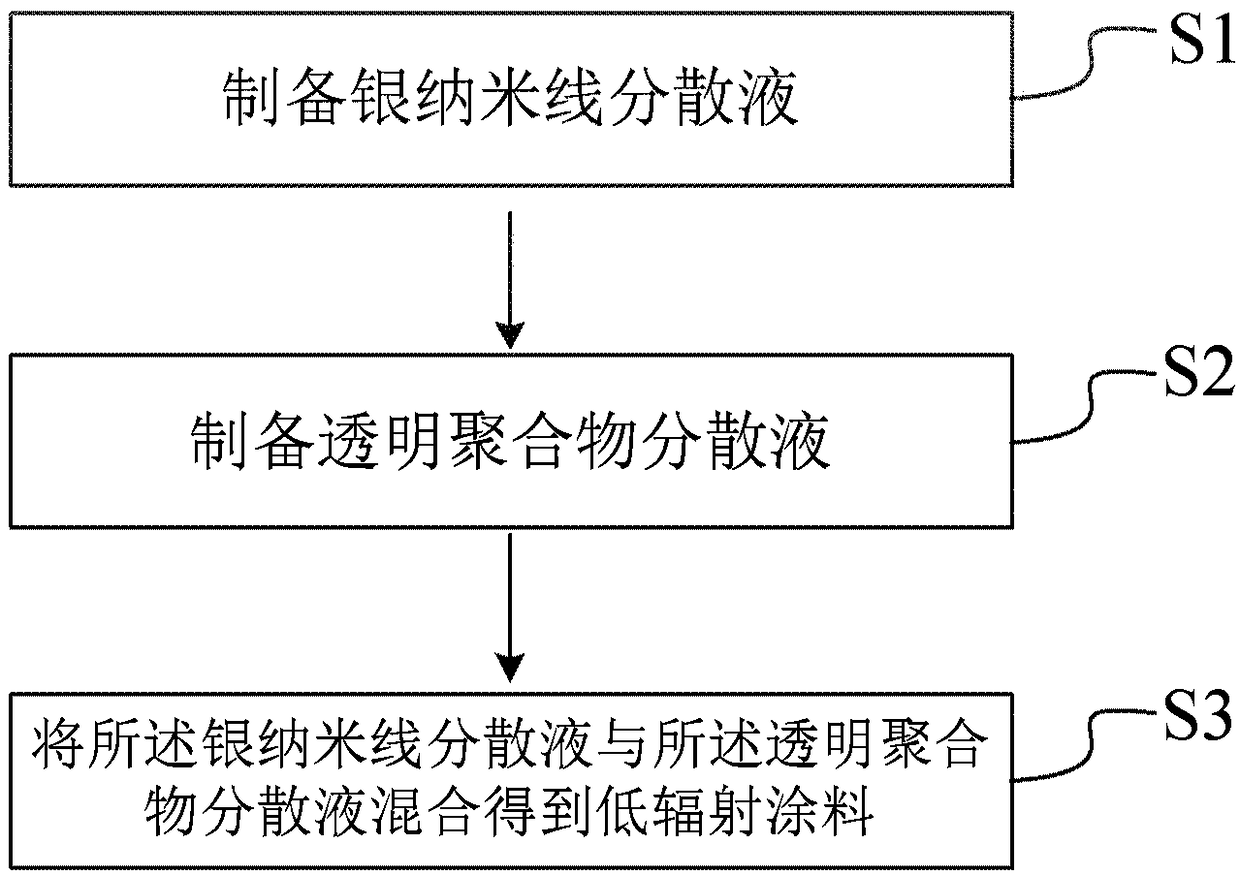

[0028] image 3 show figure 1 Flowchart of the preparation method of the low-E coating. like image 3 Shown, the preparation method of low radiation coating can comprise the steps:

[0029] S1, preparing a silver nanowire dispersion, wherein the concentration of the silver nanowire is 1-15 mg / mL;

[0030] S2, preparing a transparent polymer dispersion, wherein the mass fraction of the transparent polymer is 1-15%;

[0031] S3, mixing the silver nanowire dispersion with the transparent polymer dispersion to obtain a low-emissivity coating, where the concentration of the silver nanowires in the low-emission coating is 1-10 mg / mL.

[0032] Specifically, the polyol method can be used to prepare silver nanowire dispersions, including:

[0033] Step 1: First add a certain amount of anhydrous ethylene glycol into the spherical flask, then add an appropriate amount of PtCl 2 , heated to 160°C, and stirred with a magnetic stirrer for 10 to 20 minutes;

[0034] Step 2: Incorporat...

Embodiment 1

[0048] Preparation of low-emissivity coatings with transparent polymer as PMMA, including:

[0049] Step 11, prepare silver nano-dispersion liquid

[0050] (1) 1mL PtCl 2 Add to 10mL of anhydrous ethylene glycol, heat and keep at 160°C, stir with a magnetic stirrer to obtain a uniformly mixed solution;

[0051] (2) 5mL AgNO 3 Add 10mL of polyvinylpyrrolidone (PVP) dropwise into the mixture of (1) at the same time, and stir for 50min with a magnetic stirrer;

[0052] (3) Dilute the reactant of (2) with 50mL of acetone, separate the silver nanowires from the solvent with a centrifuge, the speed of the centrifuge is 5000rpm, and the separation time is 10min; repeat 3-5 times until the supernatant becomes colorless , pour the obtained silver nanowires into isopropanol for later use.

[0053] Step 12, prepare PMMA-anisole solution

[0054] Take 4.8g of PMMA particles into the reactor, then add 75.2mL of anisole solution, and finally stir with a magnetic stirrer for 24h.

[00...

Embodiment 2

[0058] Preparation of low-emissivity coatings with transparent polymer as TPX, including:

[0059] Step 21, preparation of silver nano-dispersion

[0060] (1) Dispense 0.5mL PtCl 2 Add to 5mL of anhydrous ethylene glycol, heat and keep at 160°C, stir with a magnetic stirrer to obtain a uniformly mixed solution;

[0061] (2) Add 3mL AgNO 3 Add 6mL of polyvinylpyrrolidone (PVP) dropwise into the mixture of (1) at the same time, and stir for 50min with a magnetic stirrer;

[0062] (3) Dilute the reactant of (2) with 25mL acetone, separate the silver nanowires from the solvent with a centrifuge, the speed of the centrifuge is 5000rpm, and the separation time is 10min; repeat 3-5 times until the supernatant becomes colorless , pour the obtained silver nanowires into isopropanol for later use.

[0063] Step 22. Preparation of TPX-cyclohexane and trichlorethylene solution

[0064] Add 25mL cyclohexane and 25mL trichlorethylene into the reactor, heat to 60°C, then add 1g of TPX, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com