Cooling composite coating for helmet and preparation method thereof

A composite coating and helmet technology, applied in the field of cooling composite coating for helmets and its preparation, can solve the problems of low near-infrared reflection efficiency, poor heat dissipation performance, poor wearer comfort, etc., and achieve excellent compatibility and bonding strength, improving durability, reducing time cost and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

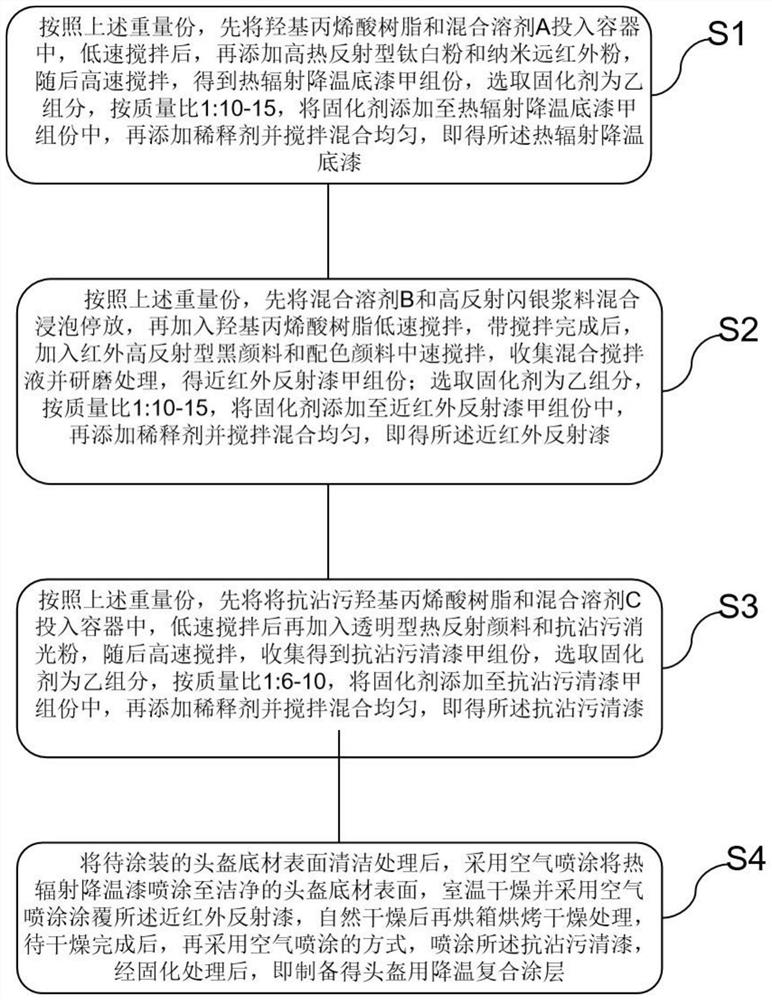

Method used

Image

Examples

Embodiment 1

[0047] Preparation of curing agent and diluent: curing agent is formed by mixing polyisocyanate curing agent and low-viscosity polyisocyanate curing agent in a weight ratio of 3:7; diluent is composed of n-butyl acetate and propylene glycol methyl ether acetate in a weight ratio of 6: 4 mixed; the preparation of thermal radiation cooling primer: by weight parts, first put 40 parts of hydroxyacrylic resin and 20 parts of mixed solvent A into the container, stir at low speed for 5 minutes, then add 20 parts of high heat reflective titanium dioxide and 10 parts of nanometer far-infrared powder, stirred at high speed for 20 minutes, to obtain component A of the thermal radiation cooling primer; then select 6 parts of curing agent as component B, mix the above components A and B together, and add 20 parts to dilute agent, stirred for 3 minutes and mixed evenly to obtain the heat radiation cooling primer.

[0048] Preparation of near-infrared reflective paint: in parts by weight, fi...

Embodiment 2-6

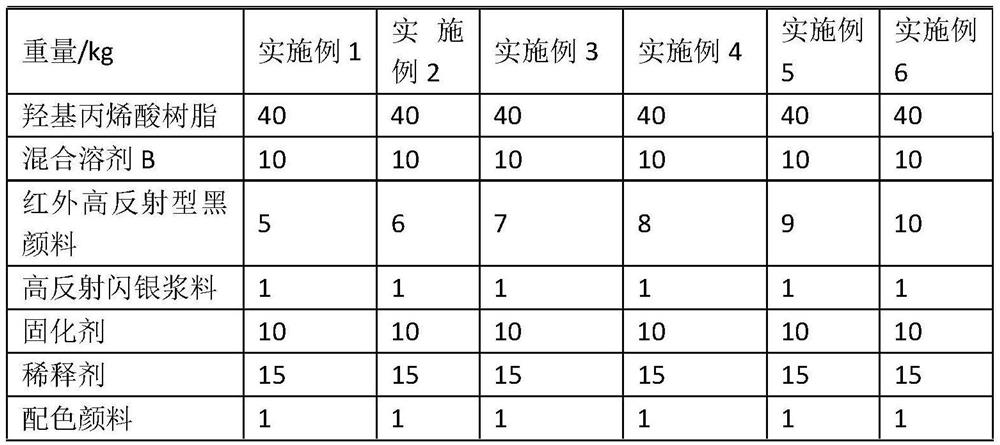

[0052] The near-infrared reflection layer in the helmet with cooling composite coating of embodiment 2-6 is different from the infrared high-reflection type black pigment raw material consumption of the near-infrared reflection layer in embodiment 1, specifically see as shown in table 1, the remaining groups The average is the same as in Example 1.

[0053] The raw material composition of the near-infrared reflective layer in the helmet with cooling composite coating in the embodiment 1-6 of table 1

[0054]

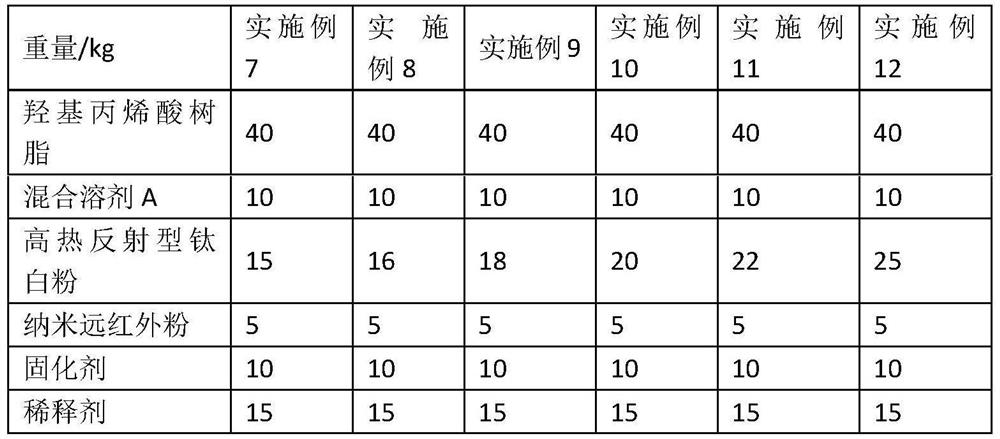

Embodiment 7-12

[0056] The amount of heat radiation cooling layer in the cooling composite coating for helmets in Examples 7-12 is different from that of the high heat reflective titanium dioxide in the heat radiation cooling layer in Example 1, as shown in Table 2 for details, and the rest of the components are the same as those in Example 1. Same as in Example 1.

[0057] The raw material composition of the thermal radiation cooling layer in the cooling composite coating for helmets in Example 7-12 of Table 2

[0058]

[0059] performance test

[0060] Performance tests were carried out on Examples 1-12, specifically testing the color of the cooling composite coating for helmets, near-infrared reflectivity, internal temperature of the helmet, water contact angle, stain resistance level and artificial aging resistance.

[0061] Detection method / test method

[0062] The overall color of the coating: visual observation;

[0063] Near-infrared reflectivity: tested by GJB 2502.2 standard; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com