Cooling composite coating for helmet and preparation method thereof

A technology for composite coatings and helmets, which is applied in the field of cooling composite coatings for helmets and its preparation. It can solve the problems of poor heat dissipation, poor wearer comfort, and low near-infrared reflection efficiency, and achieve bonding strength and compatibility. High compatibility, simple and easy overall operation, excellent compatibility and binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

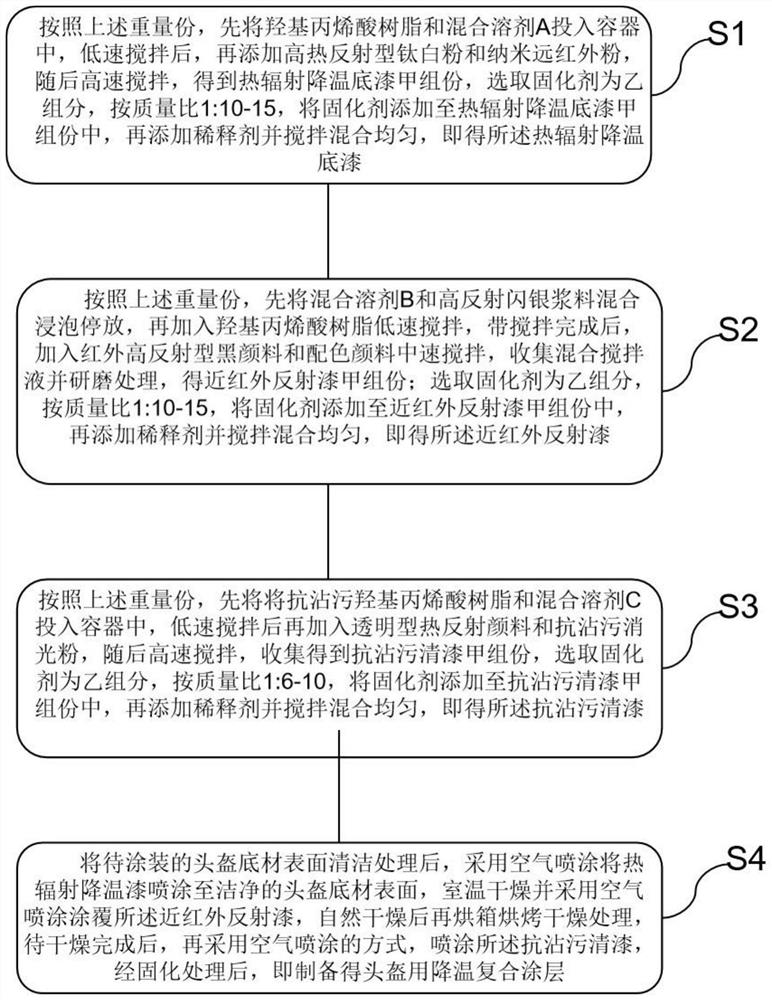

Method used

Image

Examples

Embodiment 1

[0047] Preparation of curing agent and diluent: curing agent is formed by mixing polyisocyanate curing agent and low-viscosity polyisocyanate curing agent in a weight ratio of 3:7; diluent is composed of n-butyl acetate and propylene glycol methyl ether acetate in a weight ratio of 6: 4 mixed; the preparation of thermal radiation cooling primer: by weight parts, first put 40 parts of hydroxyacrylic resin and 20 parts of mixed solvent A into the container, stir at low speed for 5 minutes, then add 20 parts of high heat reflective titanium dioxide and 10 parts of nanometer far-infrared powder, stirred at high speed for 20 minutes, to obtain component A of the thermal radiation cooling primer; then select 6 parts of curing agent as component B, mix the above components A and B together, and add 20 parts to dilute agent, stirred for 3 minutes and mixed evenly to obtain the heat radiation cooling primer.

[0048] Preparation of near-infrared reflective paint: in parts by weight, fi...

Embodiment 2-6

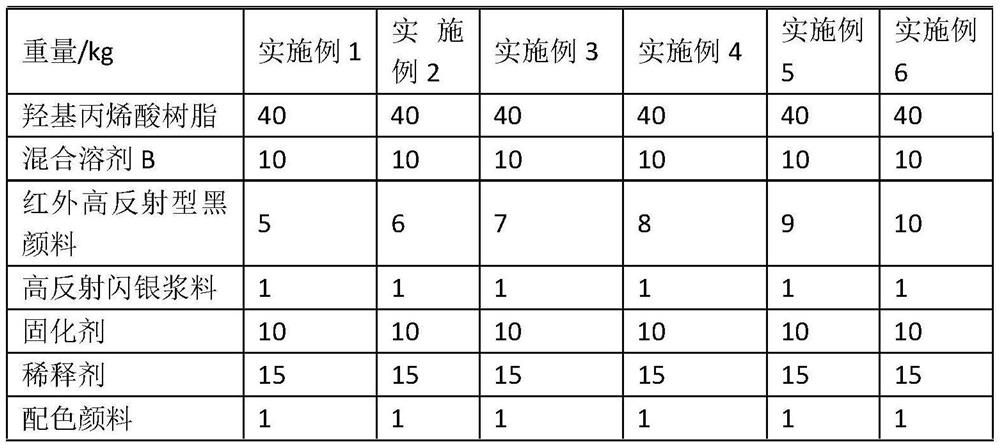

[0052] The near-infrared reflection layer in the helmet with cooling composite coating of embodiment 2-6 is different from the infrared high-reflection type black pigment raw material consumption of the near-infrared reflection layer in embodiment 1, specifically see as shown in table 1, the remaining groups The average is the same as in Example 1.

[0053] The raw material composition of the near-infrared reflective layer in the helmet with cooling composite coating in the embodiment 1-6 of table 1

[0054]

Embodiment 7-12

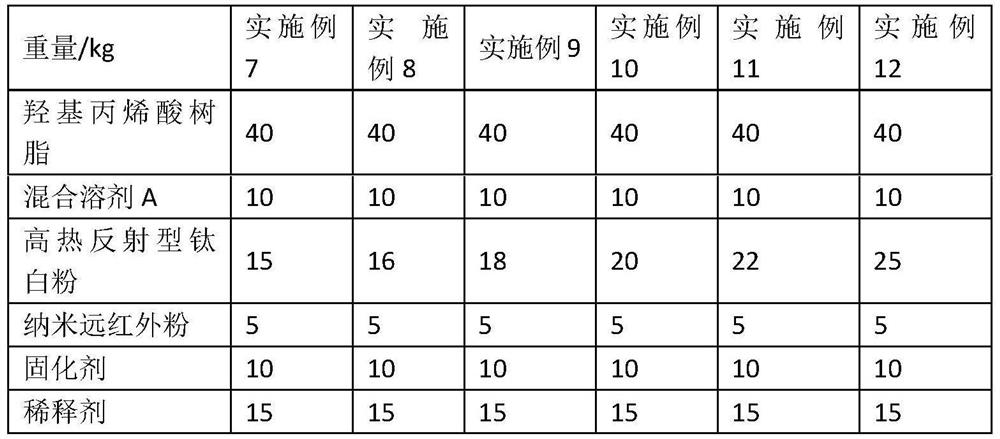

[0056] The amount of heat radiation cooling layer in the cooling composite coating for helmets in Examples 7-12 is different from that of the high heat reflective titanium dioxide in the heat radiation cooling layer in Example 1, as shown in Table 2 for details, and the rest of the components are the same as those in Example 1. Same as in Example 1.

[0057] The raw material composition of the thermal radiation cooling layer in the cooling composite coating for helmets in Example 7-12 of Table 2

[0058]

[0059] performance test

[0060] Performance tests were carried out on Examples 1-12, specifically testing the color of the cooling composite coating for helmets, near-infrared reflectivity, internal temperature of the helmet, water contact angle, stain resistance level and artificial aging resistance.

[0061] Detection method / test method

[0062] The overall color of the coating: visual observation;

[0063] Near-infrared reflectivity: tested by GJB 2502.2 standard; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com