Low-radiation thin film and preparation method thereof

A low-radiation, thin-film technology, applied to flat products, other household appliances, applications, etc., can solve the problems of high energy consumption in the preparation process, inconvenient installation, complicated process, etc., and achieve high solar heat utilization efficiency, stable structure, and infrared reflection high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Figure 5 show figure 1 A flow chart of the method for preparing the low-emissivity film 100. Such as Figure 5 As shown, the preparation method of the low-emissivity film 100 may include the following steps:

[0032] S1, providing silver nanowire dispersion liquid, wherein the concentration of silver nanowires can be 1-15 mg / mL;

[0033] S2, providing a transparent polymer dispersion, wherein the mass fraction of the transparent polymer can be 2-12%;

[0034] S3, mixing the silver nanowire dispersion liquid with the transparent polymer dispersion liquid, and the concentration of the silver nanowires in the obtained mixed liquid may be 1-10 mg / mL;

[0035] S4, providing a substrate, and forming a film of the mixed solution on the substrate; and

[0036]S5, drying the film formed on the substrate in a vacuum environment.

[0037] The solvent of the silver nanowire dispersion liquid may be isopropanol, that is, the silver nanowire-isopropanol dispersion liquid is pr...

Embodiment 1

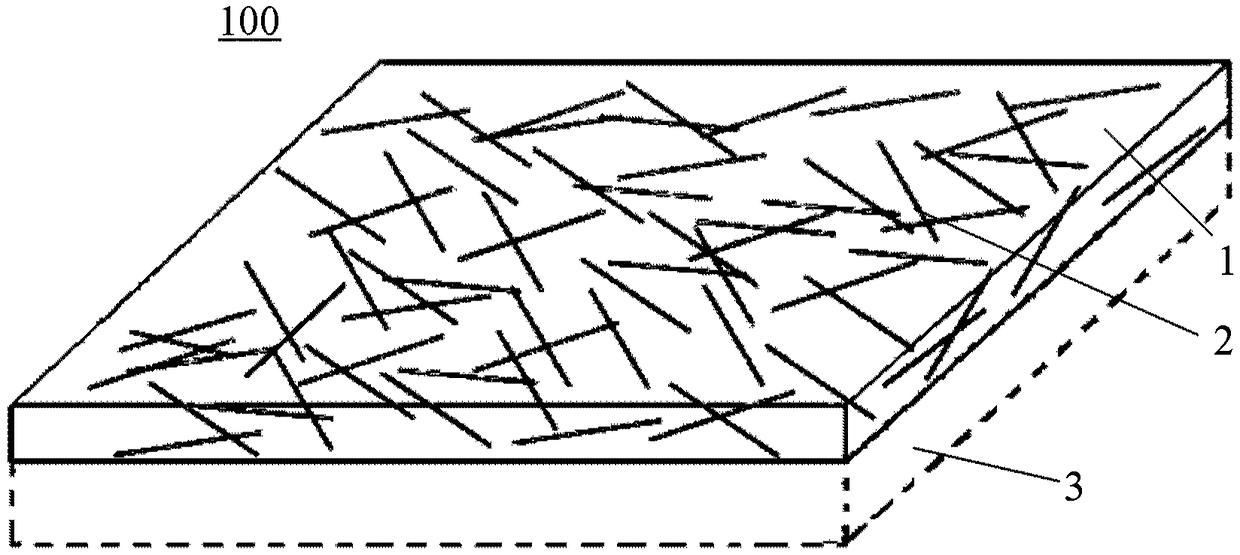

[0051] A single-layer low-emissivity film with a volume fraction of silver nanowires of 5% was prepared.

[0052] Step 1, silver nanowire is dispersed in isopropanol and obtains the silver nanowire-isopropanol dispersion liquid of 10mg / ml, and preparation mass fraction is the PMMA-anisole solution of 6%, the two are by volume ratio The ratio of 50:17 is evenly mixed;

[0053] In step 2, the glass substrate was ultrasonically cleaned with acetone and deionized water for 15 minutes in sequence, and then the glass substrate was dried under flowing nitrogen for 1 minute;

[0054] Step 3, use the glass substrate treated in step 2 as the coating substrate, and prepare a low-emissivity film with a film thickness of about 50nm-10μm by dipping pulling method; wherein, the process parameters of dipping pulling method are: drop The speed is 500-2000μm / s, the dipping time is 5s-10s, the pulling speed is 1500-3000μm / s, and the coating times are 10-50 times;

[0055] Step 4: Place the sam...

Embodiment 2

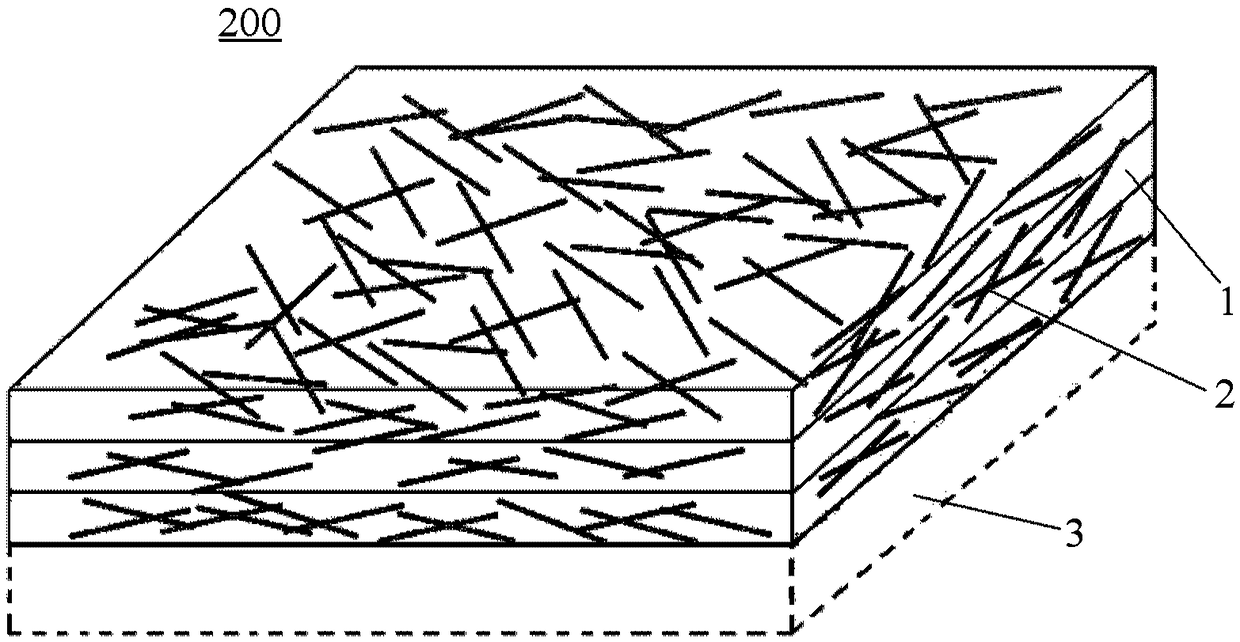

[0057] Three layers of low-emissivity films were prepared.

[0058] Adopt the method similar to embodiment 1 to prepare low-emissivity film, difference is:

[0059] The process parameters of the dipping and pulling method in step 3 are: the descending speed is 1000 μm / s, the dipping time is 5 to 10 s, the pulling speed is 2000 μm / s, and the coating times are 10 times;

[0060] In step 4, dry at a constant temperature at 100° C. for 6 hours;

[0061] Repeat steps 3 and 4 5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com