Reflecting surface of deployable antenna based on shape memory polymer and manufacturing method of skeleton structure thereof

A technology of memory polymer and skeleton structure, applied to antennas, antennas, electrical components and other directions suitable for movable objects, can solve the problems of large weight of deployable antennas, unstable deployment and contraction, complex structure, etc., and achieve convenience The expansion and contraction process, the smooth expansion movement process, and the effect of less system structure and control links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

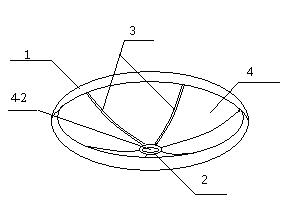

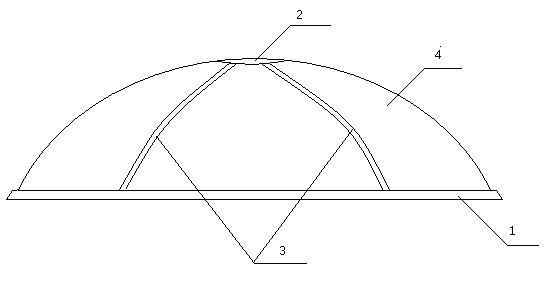

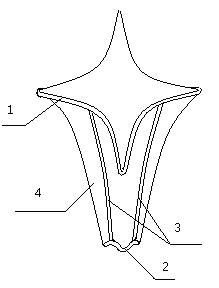

[0021] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment, a deployable antenna reflective surface based on shape memory polymer, which is composed of a hoop power member 1, a hoop stiffener 2, a radial stiffener 3 and a reflective surface 4, the reflective surface 4 It is an annular paraboloid with a circular opening 4-2 at the bottom. The upper edge of the convex paraboloid of the reflective surface 4 is fixedly connected with a hoop power part 1, and the lower edge of the convex paraboloid of the reflective surface 4 is fixedly connected with a hoop. The reinforcement 2, the reflective surface 4 between the hoop power element 1 and the hoop reinforcement 2 is provided with radial reinforcements 3 arranged in the circumferential direction, the radial reinforcement is a parabolic strip, the The hoop power member 1 , the hoop reinforcement 2 , the radial reinforcement 3 and the reflective surface 4 are all made of shape memory polymer ma...

specific Embodiment approach 2

[0024] Specific implementation mode two: The difference between this embodiment and specific embodiment 1 is that the thickness of the hoop power part 1, the hoop reinforcement part 2 and the radial reinforcement part 3 is 0.02-40mm; the radius of the hoop power part 1 is: 0.5-60m; The radius of the hoop reinforcement 2 is 0.1-2m; the ratio of the focal length of the rotating paraboloid formed by the radial reinforcement 3 and the reflective surface 4 to the aperture of the hoop power element 1 is (0.025-2.5):1.

specific Embodiment approach 3

[0025] Specific implementation mode three: The difference between this embodiment and the first embodiment is that the heating method of the reflective surface 4 is electric heating, steam heating or outer space radiation heating when the reflective surface 4 is expanded, and the heating method of the reflective surface 4 is electric heating or steam heating when it shrinks.

[0026] The movement of the reflective surface 4 from the folded and contracted state to the unfolded state is realized by electric heating, steam heating or outer space radiation heating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com